Heavy Duty Boltless Metal Shelving HN-LW328 for Logistics Warehouse, 2000kg Total Load Capacity, Longspan Racking System Manufacturer, OEM/ODM

The Heavy Duty Boltless Metal Shelving HN-LW328 is not merely a shelving unit; it is a structural storage system engineered from the ground up to be the reliable, high-capacity backbone of your logistics operation. With a staggering 2000kg total load capacity and a focus on modular flexibility, it transforms warehouse space into a pinnacle of organized strength.

Beyond Shelving: A Systems Approach to Storage

The HN-LW328 transcends the concept of simple shelving by implementing a comprehensive longspan racking system. This philosophy prioritizes interconnected strength, standardized components, and scalable design. It addresses the core triad of logistics storage needs: Maximum Capacity, Uncompromising Stability, and Operational Adaptability. The system's intelligence lies in its synergy—every component, from the vertical column to the crossbar, works in concert to create a unified, immensely strong storage bay.

Deconstructing the Strength: Core System Architecture

The exceptional performance of the HN-LW328 can be mapped to its fundamental architectural principles. The following table breaks down its key structural elements and their direct contribution to warehouse performance:

| System Component | Engineering Feature | Logistics Warehouse Benefit |

|---|---|---|

| Vertical Upright Columns | High-hardness, thickened cold-rolled steel with Diamond Hole Design. | Provides the primary load-bearing spine. Diamond holes ensure secure, torque-free beam locking that tightens under load. |

| Horizontal Beams (Longspan) | Integrated Triangular Support Gussets at connection points. | Creates a rigid, moment-resistant connection, preventing beam deflection and ensuring level shelves even under asymmetric loads. |

| Shelving Laminate (Decking) | Multi-Reinforcement Bar Backing on each panel. | Transforms the shelf from a simple plate into a structural beam, distributing weight evenly and eliminating sag for pallet racks. |

| Frame Integration | Main Frame & Add-On Frame System. | Enables infinite lateral expansion. Start with a sturdy main frame and add bays seamlessly without redundant columns, maximizing accessible space. |

| Material & Finish | Electrostatic Powder Coating on a cold-rolled steel substrate. | Provides a corrosion-resistant, scratch-resistant shield against warehouse environmental factors, ensuring long-term integrity. |

1. The Foundation: Ultra-High Load Capacity Explained

The headline 2000kg total capacity is a promise backed by physics. This starts with the use of commercial-grade cold-rolled steel, chosen for its superior yield strength and structural uniformity compared to hot-rolled alternatives. This material is formed into robust column profiles and deep-beam channels. Crucially, the load-bearing design is systemic: the capacity is achieved through the combined strength of the reinforced laminate shelves distributing weight to the beams, which then transfer the load through the secured triangular connections into the primary columns. This holistic approach ensures safe performance across the entire structure, not just at isolated points.

2. The Boltless Advantage: Speed, Safety, and Adaptability

In a logistics environment, time is throughput. The HN-LW328's patent-pending boltless connection system is a game-changer. Beams engage with the columns via a butterfly hole bayonet mechanism that locks securely with a simple turn. This system:

Eliminates Tools: Assembly and reconfiguration require no wrenches, sockets, or drills.

Enables Rapid Re-Slotting: Adjust shelf heights in minutes to accommodate different pallet heights or to reconfigure storage zones for seasonal goods.

Enhances Safety: The positive-lock design provides a visible, audible confirmation of secure engagement, reducing human error.

3. Unshakeable Stability: The Geometry of Reliability

Heavy loads and forklift traffic demand inherent stability. The HN-LW328 incorporates strategic triangular bracing at all critical beam-to-column junctions. The triangle is nature's most stable geometric shape, and its application here prevents racking (parallelogram deformation) of the frame. This, combined with the wide-stance, welded base plates at the column feet, creates a unit that stands firm against incidental impacts and dynamic loading, providing a critical safety margin.

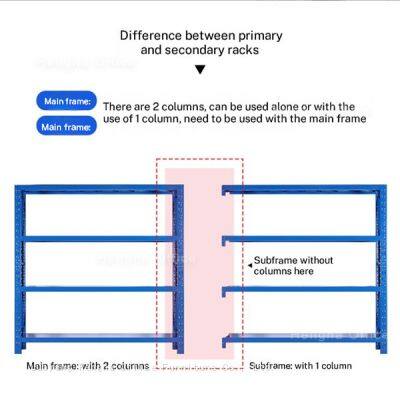

4. The Longspan Flexibility: Main & Add-On Framework

This system intelligently distinguishes between Main Frames and Add-On Frames.

A Main Frame is a complete, free-standing unit with two connected columns. It is the anchor of your system.

An Add-On Frame is a single-column unit designed to connect directly to a Main Frame, extending the shelving bay.

This design allows you to create long, continuous runs of shelving without a forest of redundant columns at the junctions. The result is maximized accessible storage space, fewer obstructions for forklifts and personnel, and a cleaner, more organized warehouse layout.

Technical Specifications & Configuration Data

Model Series: HN-LW328 (Heavy Duty Longspan)

Primary Application: Logistics Warehousing, Bulk Storage, Pallet Racking (non-palletized)

Structural Material: Premium Cold-Rolled Steel, Upgraded Thickness

Total System Capacity: Up to 2000kg (Evenly distributed across all levels)

Beam Span: Available in multiple longspan lengths (e.g., 96", 108", 120")

Assembly: 100% Boltless Snap-In Design

Finish: Durable Electrostatic Powder Coat (Standard Grey, other colors available)

Compliance: Engineered to meet or exceed relevant commercial storage equipment standards.

Ideal Applications in the Logistics Chain

The HN-LW328 system is the optimal choice for:

Centralized Distribution Centers storing mixed SKUs.

Manufacturing Plant Raw Material & Finished Goods Warehousing.

Third-Party Logistics (3PL) Facilities requiring flexible, client-agnostic storage.

Retail Back-of-House Inventory Storage.

Storage of bulky, heavy items like automotive parts, machinery components, or packaged goods.

Frequently Asked Questions (FAQ)

Q1: How is the 2000kg total capacity calculated and ensured?

A: The 2000kg total capacity is a conservative engineering rating based on the system's weakest link under uniformly distributed loads. It involves rigorous load testing and structural analysis of the entire assembly—columns, beams, connections, and laminate. This rating assumes the weight is evenly distributed across all shelf levels. For example, on a 5-shelf unit, this implies approximately 400kg per level. It is crucial to never exceed the per-level load rating specified for your beam length and laminate type, as point loads (concentrated weight in a small area) require separate consideration.

Q2: Can this system handle pallet racking with forklifts?

A: The HN-LW328 is an excellent boltless longspan shelving unit designed for very heavy loads. However, for true pallet racking where entire pallets are placed and removed directly by forklift tines, we recommend our dedicated pallet rack systems. The HN-LW328 is perfect for manual loading/unloading of palletized goods (e.g., with a pallet jack) or for storing heavy, non-palletized bulk items. The key distinction is the direct, dynamic impact force from forklift engagement, for which a different beam profile and safety lock is engineered.

Q3: What is the lead time for OEM/ODM configurations, and what can be customized?

A: As a professional manufacturer, we welcome OEM/ODM projects. Standard models have shorter lead times. For customizations—including specific dimensions (height, depth, width), unique powder coat colors (RAL matched), specialized laminate types (wire mesh, particle board), or custom load capacity engineering—lead times vary based on complexity. Typically, engineering review and production for a custom order takes between 4-8 weeks after final specifications are approved. Contact our engineering sales team with your layout plans for a precise quote and timeline.

Engineer Your Warehouse for Peak Performance

In logistics, storage is not an overhead; it is a critical component of operational velocity and cost control. The Heavy Duty Boltless Metal Shelving HN-LW328 provides a future-proof foundation, combining brute strength with intelligent, adaptable design. It is an investment that reduces handling time, maximizes cube utilization, and stands the test of time.

The contact information of the sales manager is shown in the picture below. You can make inquiries directly without waiting.

Send Inquiry to This Supplier

You May Also Like

-

Industrial Strength Shelving System 400kg Capacity Per Level - Heavy Duty Supermarket Storage Rack for Retail Space OptimizationUS$ 1 - 330MOQ: 5 Sets

-

400kg Load Capacity Industrial Racking System - Warehouse Heavy Duty Storage Unit With Butterfly Hole Plug-In DesignUS$ 1 - 330MOQ: 5 Sets

-

Multi-Layer Industrial Storage Unit 400kg Per Shelf - Space-Saving Library Shelving Solution With Freely Adjustable LayerUS$ 1 - 330MOQ: 5 Sets

-

Robust Industrial Storage Solution- Heavy Duty Medical Shelving Rack for Hospital Clinics and Healthcare FacilitiesUS$ 1 - 330MOQ: 5 Sets

-

Heavy Duty Steel Shelving Bay 200kg Capacity - Industrial Workshop Storage Rack With Butterfly Snap DesignUS$ 1 - 330MOQ: 5 Sets

-

Heavy Duty Parts Storage Rack 300kg Capacity - Workshop Organizer With Main-Subframe DesignUS$ 1 - 330MOQ: 5 Sets

-

Industrial Parts Shelving System 300kg Load Capacity - Garage Storage Solution With Four Reinforcement BarsUS$ 1 - 330MOQ: 5 Sets

-

Customizable Parts Organizer 300kg Per Shelf - Multi-Size Workshop & Factory Storage Rack With High-Quality Cold Rolled SteelUS$ 1 - 330MOQ: 5 Sets

-

Space-Saving Parts Storage Unit 300kg Capacity - Warehouse & Courier Shelving System With Free Combination Main-Subframe DesignUS$ 1 - 330MOQ: 5 Sets

-

Industrial Modular Warehouse Shelving - Heavy Duty Storage Rack With Chipboard Deck for Factory & Workshop OperationsUS$ 1 - 330MOQ: 5 Sets