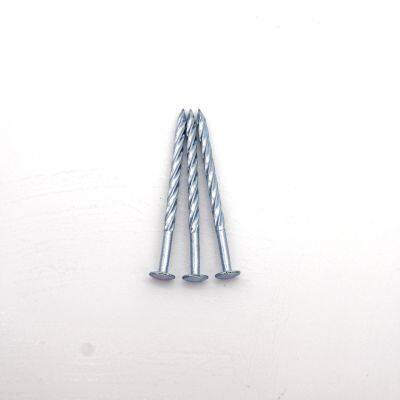

Twisted Shank Nails Q195 Material for Heavy-Duty Construction

Established in 2005, Linyi Power Metal Products Co., Ltd is a dedicated manufacturer based in Linyi, Shandong, China, with over 15 years of expertise in producing high-quality metal products. Our factory, spanning 1,000-3,000 square meters and staffed by 51-100 skilled employees, ensures precision in every batch of Twisted Shank Nails made from Q195 material, designed specifically for heavy-duty construction needs. These nails offer exceptional durability and reliability, reducing maintenance costs and enhancing safety in demanding projects. With an annual export value of US$1 million to US$1.5 million and shipments handled through Qingdao Port, we serve key markets like South America, Southeast Asia, and Africa, delivering consistent quality that builders trust worldwide.

Our Twisted Shank Nails are engineered to provide superior performance in construction applications. The unique twisted shank design increases friction and resistance to pull-out, ensuring a secure hold in wood, concrete, and other materials, while the Q195 steel material offers excellent strength and corrosion resistance. Key features include:

- Enhanced Durability: Q195 steel provides high tensile strength, making these nails ideal for long-term use in harsh environments without bending or breaking.

- Improved Safety: The twisted shank prevents loosening over time, reducing the risk of structural failures in heavy-duty projects like framing, roofing, and decking.

- Versatile Applications: Suitable for a wide range of construction tasks, from residential buildings to industrial infrastructure, ensuring reliable fastening solutions.

- Cost-Effective: By minimizing replacement needs and installation time, these nails help clients save on labor and material expenses over the project lifecycle.

Technical specifications can be tailored to meet specific requirements, but common parameters include customizable dimensions for optimal fit. Below is a table summarizing typical size options available upon request:

| Parameter | Range | Description |

| Length | 50mm - 150mm | Adjustable for various material thicknesses |

| Diameter | 2.5mm - 5.0mm | Designed for optimal strength and penetration |

| Shank Twist Angle | 30° - 45° | Standard twist for maximum grip enhancement |

| Surface Finish | Galvanized or Plain | Optional coatings for corrosion resistance |

With a proven track record, Linyi Power Metal Products Co., Ltd leverages its extensive export experience to markets such as the Middle East and South Asia, ensuring efficient logistics and timely deliveries via Qingdao Port. Our commitment to quality, backed by a dedicated team and modern facilities, makes these Twisted Shank Nails a smart choice for your heavy-duty construction needs, offering unmatched reliability and value. Reach out to us today for customized quotes or to discuss how our products can elevate your projects—let's build stronger together.

Frequently Asked Questions (FAQ):

-

Q: What is Q195 material, and why is it used for these nails?

A: Q195 is a carbon steel grade known for its good weldability and strength, making it ideal for construction nails that require durability and resistance to deformation under heavy loads. -

Q: How does the twisted shank design benefit heavy-duty construction?

A: The twisted shank increases surface friction, preventing nails from loosening in materials like wood or concrete, which enhances structural integrity in high-stress applications such as framing or roofing. -

Q: Are these nails available in different sizes or finishes?

A: Yes, sizes and finishes like galvanized or plain are customizable upon request to suit specific project requirements, ensuring optimal performance and corrosion protection. -

Q: What applications are these nails best suited for?

A: They are designed for heavy-duty tasks such as building foundations, deck installations, and industrial structures, where strong, reliable fastening is critical. -

Q: Can I request custom packaging or bulk orders?

A: Absolutely, we offer flexible packaging options including bulk shipments or custom packing to meet your logistical needs, with details available upon inquiry. -

Q: What is the typical lead time for orders, especially for export markets?

A: Lead times vary based on order size and customization but are optimized for efficiency, with shipments typically processed through Qingdao Port for global markets like South America and Africa. -

Q: How does your company ensure product quality?

A: As a manufacturer with a 1,000-3,000 square meter facility, we implement rigorous quality control processes throughout production to ensure consistent, high-standard nails that meet industry demands. -

Q: Are there any special handling or storage recommendations?

A: Store in a dry, cool environment to prevent rust; for galvanized versions, this extends longevity, but standard care is sufficient for most conditions.

Send Inquiry to This Supplier

You May Also Like

-

Twisted Shank Nails for Timber Connectors in Structural EngineeringNegotiableMOQ: 5 Metric Tons

-

Twisted Shank Nails ASTM F1667 Compliant for Structural ApplicationsNegotiableMOQ: 5 Metric Tons

-

Spiral Shank Nails Electro-Galvanized Surface for Corrosion ResistanceNegotiableMOQ: 5 Metric Tons

-

Spiral Shank Nails With Mill Test Report and WarrantyNegotiableMOQ: 5 Metric Tons

-

Twisted Shank Nails 1.5mm-4.0mm Diameter for Heavy-Duty ConstructionNegotiableMOQ: 5 Metric Tons

-

Twist Nails Factory Direct Supply With Custom Packaging OptionsNegotiableMOQ: 5 Metric Tons

-

Twist Nails 50mm-150mm Length With Helical Threads for Wood FramingNegotiableMOQ: 5 Metric Tons

-

Spiral Shank Nails High Tensile Strength for Concrete FormworkNegotiableMOQ: 5 Metric Tons

-

Twisted Shank Nails for Timber Construction and Pallet ManufacturingNegotiableMOQ: 5 Metric Tons

-

Twist Nails Q195 Low Carbon Steel With Zinc Plating for Enhanced GripNegotiableMOQ: 5 Metric Tons