Twisted Shank Nails Compliant With ASTM Standards for Construction

As a dedicated manufacturer with over 18 years of experience, Linyi Power Metal Products Co., Ltd proudly introduces our high-quality Twisted Shank Nails, engineered to comply with ASTM standards for superior construction applications. Established in 2005 and based in Linyi, Shandong, China, we leverage our expertise to produce reliable fastening solutions that meet global demands, with exports spanning South America, Southeast Asia, Africa, Mid East, and South Asia. Our commitment to innovation ensures these nails deliver exceptional holding power, reducing the risk of structural failures in buildings. With a focus on durability and performance, we provide products that cater to diverse construction needs, backed by our extensive industry knowledge and customer-centric approach. This product represents our dedication to enhancing safety and efficiency in the building sector.

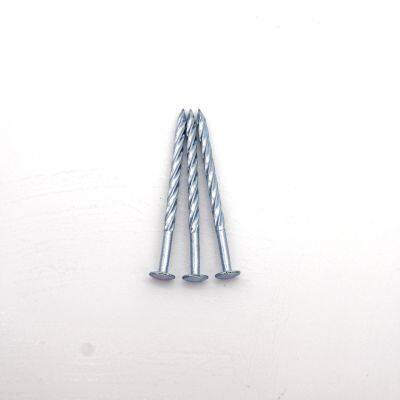

The Twisted Shank Nails feature a unique design that significantly increases pull-out resistance, making them ideal for demanding construction environments. Key characteristics include:

- Enhanced Grip Technology: The twisted shank design creates superior friction when driven into materials, preventing loosening over time and ensuring long-term stability in structures like wooden frames and roofing.

- Corrosion Resistance: A galvanized finish protects against rust and environmental wear, extending the lifespan of the nails even in humid or coastal conditions, which reduces maintenance costs for end-users.

- ASTM Compliance: Rigorously tested to meet ASTM standards, these nails guarantee consistent quality, safety, and reliability, providing peace of mind for builders and contractors in critical applications.

- Versatile Applications: Suitable for a wide range of construction tasks, including framing, sheathing, and decking, offering flexibility and efficiency on job sites.

Technical specifications are detailed in the table below, highlighting common parameters to help buyers make informed decisions. This data underscores the product's adaptability and performance benefits.

| Length (inches) | Diameter (inches) | Recommended Use |

|---|---|---|

| 1.0 - 1.5 | 0.1 - 0.12 | Light framing, trim work |

| 2.0 - 2.5 | 0.13 - 0.15 | General construction, sheathing |

| 3.0 - 4.0 | 0.16 - 0.2 | Heavy-duty framing, decking |

Advantages for customers include reduced installation time due to the nails' easy driving capability, lower replacement frequency from their durable construction, and improved structural integrity that minimizes project risks. These benefits translate to cost savings and enhanced productivity on construction sites. For instance, the twisted shank prevents nail pop in drywall or wood, ensuring smoother finishes and fewer callbacks.

Supported by our robust manufacturing infrastructure, including a 1,000-3,000 square meter factory and a skilled team of 51-100 employees, we consistently achieve an annual export value of US$1 Million - US$1.5 Million, with shipments efficiently handled via Qingdao Port. Our presence in key markets like South America and Southeast Asia demonstrates our reliability and global reach. Trust in our product for dependable performance and explore how our Twisted Shank Nails can elevate your construction projects—contact us today for tailored solutions and competitive quotes.

Frequently Asked Questions (FAQ)

-

Q: What makes twisted shank nails different from standard nails?

A: The twisted shank design increases surface friction, providing better holding power and resistance to pull-out, which is essential for structural stability in construction. -

Q: Why is ASTM compliance important for these nails?

A: ASTM standards ensure the nails meet rigorous quality and safety benchmarks, reducing risks of failure in building applications and ensuring consistent performance. -

Q: What sizes are available for these nails?

A: We offer a range from 1 inch to 4 inches in length, with diameters varying by application; specific sizes can be customized upon request. -

Q: Are these nails suitable for outdoor use?

A: Yes, the galvanized finish provides corrosion resistance, making them ideal for outdoor projects like decks and roofing in various climates. -

Q: What is the minimum order quantity (MOQ)?

A: MOQ is flexible and can be discussed based on your needs; we accommodate both small and bulk orders to suit different project scales. -

Q: How long does shipping take from Qingdao Port?

A: Lead times vary by destination but are typically efficient; we provide estimated delivery schedules upon order confirmation to ensure timely project completion. -

Q: Can I request custom packaging for these nails?

A: Absolutely, packaging options are customizable, including bulk boxes or smaller units, to meet your logistical and handling preferences. -

Q: What applications are these nails best for?

A: They excel in construction framing, woodworking, and other building tasks where enhanced grip and durability are critical for long-term integrity.

Send Inquiry to This Supplier

You May Also Like

-

Twisted Shank Nails 1.5mm-4.0mm Diameter for Heavy-Duty ConstructionNegotiableMOQ: 5 Metric Tons

-

Twist Nails Factory Direct Supply With Custom Packaging OptionsNegotiableMOQ: 5 Metric Tons

-

Twist Nails 50mm-150mm Length With Helical Threads for Wood FramingNegotiableMOQ: 5 Metric Tons

-

Spiral Shank Nails High Tensile Strength for Concrete FormworkNegotiableMOQ: 5 Metric Tons

-

Twisted Shank Nails for Timber Construction and Pallet ManufacturingNegotiableMOQ: 5 Metric Tons

-

Twist Nails Q195 Low Carbon Steel With Zinc Plating for Enhanced GripNegotiableMOQ: 5 Metric Tons

-

Twist Nails for Roofing and Decking With Superior Holding PowerNegotiableMOQ: 5 Metric Tons

-

Spiral Shank Nails for Enhanced Bonding in Plywood AssemblyNegotiableMOQ: 5 Metric Tons

-

Twisted Shank Nails 2.5mm Diameter for Industrial RoofingNegotiableMOQ: 5 Metric Tons

-

Screw Shank Nails With 1-Year Warranty for Reliable FasteningNegotiableMOQ: 5 Metric Tons