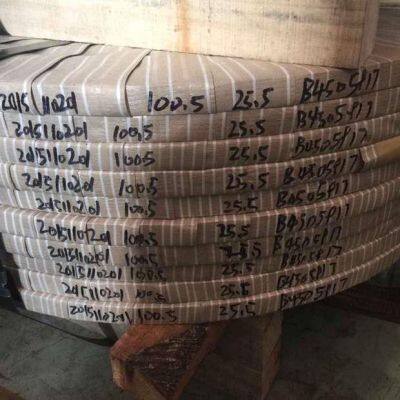

High Magnetic Permeability DT4C Cold Rolled Electrical Steel Coil 600mm Width

Shanxi Jurun Technology Co., Ltd., a specialized manufacturer based in Taiyuan, China, proudly presents our High Magnetic Permeability DT4C Cold Rolled Electrical Steel Coil. Engineered for exceptional electromagnetic performance, this 600mm-wide coil delivers reduced energy loss and enhanced efficiency in critical electrical applications. Our state-of-the-art production facility ensures precise control over grain orientation and surface quality, providing reliable material solutions for power-intensive industries worldwide.

Key Technical Advantages:

- Superior Magnetic Properties: Optimized grain structure achieves permeability up to 1,800 mH/m (B50 value), significantly improving flux density in rotating machinery.

- Precision Thickness Control: Consistent 0.5mm thickness with ±0.02mm tolerance ensures uniform laminations for vibration reduction.

- Customizable Insulation Coating: Optional C3/C4/C5 surface treatments provide interlamination resistance of 5-20 Ω·cm² per layer.

- Low Core Loss: P1.5/50 values as low as 2.8 W/kg minimize heat generation under high-frequency operation.

Performance Specifications:

| Parameter | Standard Value | Testing Standard |

| Thickness Tolerance | ±0.02mm | GB/T 2521 |

| Coil Inner Diameter | 508mm (Standard) | Customizable |

| Surface Roughness (Ra) | ≤0.5μm | ISO 4287 |

| Flatness | ≤5mm/m | ASTM A1038 |

This electrical steel coil enables manufacturers to achieve:

- 15-20% higher power density in transformer cores compared to conventional grades

- Reduced audible noise (3-5 dB lower) in motor applications due to precise thickness control

- Extended service life through corrosion-resistant coating options

With over 12 years of metallurgical expertise in Shanxi's industrial hub, our factory maintains strict process controls from smelting to slitting. All coils undergo triple-check quality verification including Epstein frame testing, ensuring magnetic properties meet project specifications. We support customized orders with technical consultation for specific application requirements - from alternative widths (400-1200mm) to specialized annealing treatments.

FAQ Section:

-

Q: What is the maximum coil weight available?

A: Standard coils weigh 3-5 metric tons, but we can accommodate up to 10-ton coils for high-volume orders. -

Q: Can you provide material certification?

A: Yes, each shipment includes Mill Test Certificates with actual magnetic properties and chemical composition. -

Q: What packaging ensures ocean freight protection?

A: We use triple-layer waterproof wrapping with steel pallets and corner guards, meeting IP67 standards. -

Q: Is laser cutting compatible with this material?

A: Absolutely. Our surface-controlled coils maintain consistent kerf width with -

Q: How does DT4C compare to DW470 in motor applications?

A: DT4C offers 12% lower core loss at 400Hz frequencies, making it preferable for high-speed EV motors. -

Q: What lead time applies for 20-ton orders?

A: Standard specification orders ship within 15 days. Custom coatings may add 5-7 days.

Send Inquiry to This Supplier

You May Also Like

-

DT4C Super Grade Pure Iron Coil Stock With Low Coercivity and Stable Magnetic PropertiesNegotiableMOQ: 1 Ton

-

DT4C Coil Stock Pure Iron Cold Rolled Coil for DC Motor Housings in Aviation and Defense IndustriesNegotiableMOQ: 1 Ton

-

Electrical Pure Iron Coil Stock High Purity Electromagnetic Iron Coil With Excellent Cold Workability for StampingNegotiableMOQ: 1 Ton

-

Industrial Pure Iron Coil for Magnetic Shielding Equipment, Superior Shielding EffectivenessNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Coil Bright Annealed, Tolerance Compliant With GB/T 708 StandardNegotiableMOQ: 1 Ton

-

Customizable Grades DT4, DT4A, DT4E Pure Iron Coil for Versatile Electromagnetic ComponentsNegotiableMOQ: 1 Ton

-

Pure Iron Coil DT4C Cold Rolled Coil for Automotive Electrical Parts: Regulators, Starters, and HornsNegotiableMOQ: 1 Ton

-

Industrial Pure Iron Coil Stock With Surface Quality Meeting GB/T 13237 for Welding and PlatingNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Coil DT4C Cold Coil Density 7.85 G/cm³, Tensile Strength 176-274MPaNegotiableMOQ: 1 Ton

-

Cold Rolled Pure Iron For Instrumentation: High-Resolution Pole Pieces Material, Pure Iron DT4C Cold Rolled CoilNegotiableMOQ: 1 Ton