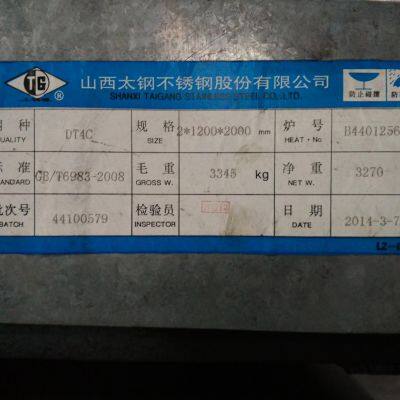

Soft Magnetic Cold Rolled Thin Sheet (Pure Iron) for Efficient Energy Conversion

Shanxi Jurun Technology Co., Ltd., located in the industrial hub of Taiyuan, China, specializes in manufacturing premium soft magnetic cold rolled thin sheets made from pure iron. These advanced materials are engineered to deliver exceptional magnetic performance while minimizing energy loss during conversion processes. Our sheets serve as fundamental components in electrical applications where efficiency directly impacts operational costs and environmental footprint.

With over a decade of metallurgical expertise, we've refined our production process to achieve industry-leading consistency in magnetic properties and surface quality. The pure iron composition ensures predictable performance across varying electromagnetic conditions, making our product a reliable choice for precision applications. Below are key technical specifications presented for clarity:

| Parameter | Value | Measurement |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ISO 9444 |

| Saturation Flux Density | ≥2.15T | ASTM A341 |

| Coercive Force | ≤80 A/m | IEC 60404 |

| Resistivity | 0.1 μΩ·m | Room temperature |

Our cold rolling technique produces sheets with ultra-smooth surfaces (Ra ≤ 0.5μm) that reduce eddy current losses by up to 15% compared to conventional methods. The material's homogeneous grain structure contributes to three primary advantages:

- Reduced Hysteresis Loss: Minimizes heat generation during cyclic magnetization

- Enhanced Permeability: Accelerates magnetic field establishment for responsive devices

- Improved Thermal Stability: Maintains consistent performance from -40°C to 120°C

These properties translate to tangible benefits for equipment manufacturers. When used in transformer cores, our sheets can increase energy transfer efficiency by 3-5%, significantly lowering electricity consumption over the product lifecycle. Motor applications benefit from reduced cogging torque and quieter operation, while sensor manufacturers achieve higher signal-to-noise ratios.

Shanxi Jurun Technology operates a fully integrated production facility with strict quality control protocols. Each batch undergoes:

- Spectroscopic composition analysis

- Magnetic property verification using Epstein frame

- Surface flatness inspection via laser scanning

We offer flexible customization including annealing treatments (optional) for specific coercivity requirements and slit-to-width services. Technical support is available throughout the design phase to help optimize your electromagnetic systems.

Backed by Shanxi Jurun's reputation for supplying major Chinese electrical manufacturers since 2010, these sheets represent a proven solution for energy-critical applications. Our Taiyuan-based plant maintains sufficient inventory for rapid delivery of standard sizes, while custom orders typically ship within 3 weeks. Contact our engineering team today to discuss how our pure iron magnetic sheets can enhance your product performance and contribute to sustainable energy utilization.

Frequently Asked Questions:

Q1: What makes pure iron preferable to silicon steel in certain applications?

A: Pure iron offers higher saturation flux density (2.15T vs 2.0T in typical Si-steel), making it suitable for compact designs where space constraints exist. It also exhibits better ductility for complex stamping operations.

Q2: Can these sheets be used in high-frequency applications?

A: While primarily optimized for 50-400Hz operation, we offer special annealing processes that can extend effective frequency range up to 1kHz. Please consult our technical datasheets.

Q3: Do you provide anti-corrosion treatments?

A: Standard products have no coating, but phosphating or nickel plating is available upon request for harsh environments.

Q4: What packaging options are available?

A: Sheets are typically supplied in moisture-proof paper with wooden pallets. VCI (Vapor Corrosion Inhibitor) packaging can be arranged for international shipments.

Q5: How does thickness affect magnetic performance?

A: Thinner gauges (0.1-0.2mm) reduce eddy current losses at higher frequencies, while thicker sheets (0.3-0.5mm) provide better mechanical rigidity. Our engineers can recommend optimal thickness based on your operating frequency.

Q6: What is the minimum order quantity?

A: Standard sizes have no MOQ, while custom dimensions require 500kg minimum per specification.

Q7: Can you supply pre-annealed material?

A: Yes, we offer stress relief annealing (hydrogen atmosphere optional) to achieve specific magnetic properties. Certificates of analysis are provided.

Q8: How do I request material certification?

A: All shipments include mill test reports covering chemical composition and magnetic properties. Additional third-party certification is available upon request.

Send Inquiry to This Supplier

You May Also Like

-

EN 10130 DC01 Cold Rolled Electromagnetic Pure Iron Sheet for Magnetic CircuitsNegotiableMOQ: 1 Ton

-

Precision Cold Rolled Electromagnetic Pure Iron Sheet With Superior Magnetic ConductivityNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Cold Rolled Steel Sheet With Excellent Formability & WeldabilityNegotiableMOQ: 1 Ton

-

Electrical Pure Iron Cold Rolled Coil/Sheet With Excellent Deep Drawing PropertiesNegotiableMOQ: 1 Ton

-

Cold Rolled Pure Iron Sheet 0.5-3.0mm Thickness for Electromagnetic ComponentsNegotiableMOQ: 1 Ton

-

Soft Magnetic Pure Iron Sheet With Minimum Iron Loss for High-Efficiency MotorsNegotiableMOQ: 1 Ton

-

Electrical Pure Iron Cold Rolled Sheet DT4C Grade for Industrial ApplicationsNegotiableMOQ: 1 Ton

-

Ultra-Low Carbon Cold Rolled Sheet Loss Electrical Pure Iron CR Sheet With High Magnetic PermeabilityNegotiableMOQ: 1 Ton

-

Electrical Pure Iron CR Sheet With Superior Surface Quality for Precision StampingNegotiableMOQ: 1 Ton

-

High Purity Cold Rolled Electrical Pure Iron Sheet for Transformers and MotorsNegotiableMOQ: 1 Ton