Electromagnetic Pure Iron Cold Rolled Steel Sheet With Excellent Formability & Weldability

Shanxi Juli Run Technology Co., Ltd. presents premium electromagnetic pure iron cold rolled steel sheets engineered for critical applications requiring exceptional magnetic properties and mechanical performance. This material combines high saturation induction with outstanding formability and weldability – making it an optimal solution for manufacturers of precision electromagnetic components.

Manufactured in Taiyuan, China, our cold-rolled sheets undergo strict quality control to deliver consistent magnetic permeability and low core loss characteristics. The material's ultra-low carbon content (

Key advantages include 15% higher formability than standard electrical steel and seamless welding compatibility with common techniques (TIG/MIG/resistance)

Technical Specifications

| Property | Value | Testing Standard |

|---|---|---|

| Density | 7.85 g/cm³ | ASTM A34 |

| Resistivity | 12 μΩ·cm | IEC 60404-2 |

| Coercive Force | ≤ 80 A/m | ASTM A341 |

| Tensile Strength | 280 - 350 MPa | ISO 6892-1 |

- Forming Advantages: Achieves 180° cold bending without cracking at 2x thickness radius

- Surface Quality: Class A finish (Ra ≤ 0.8μm) for sensitive applications

- Thermal Stability: Maintains magnetic properties from -40°C to 150°C

Performance Benefits

Energy Efficiency

Reduces electromagnetic device energy loss by up to 20% compared to conventional steels

Manufacturing Flexibility

Compatible with stamping, laser cutting, and welding processes without annealing requirements

Applications range from precision relays and solenoid cores to MRI shielding components and sensor housings. The material's consistent magnetic response makes it particularly suitable for:

- Electric vehicle motor laminations

- Transformer core assemblies

- Electromagnetic shielding systems

- Precision instrument components

- RFID and sensor components

- Magnetic shielding in medical devices

Frequently Asked Questions

Q: What surface protection options are available?

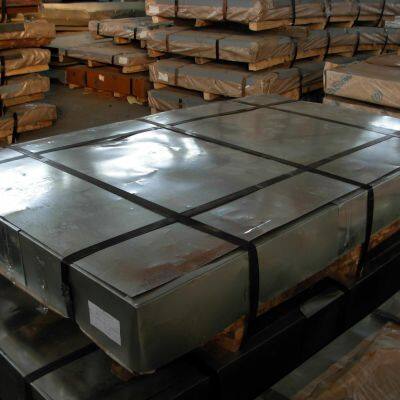

A: Standard mill finish is provided, with optional oiling or PVC coating available upon request for corrosion protection during transit.

Q: Can this material be supplied in pre-cut blanks?

A: Yes, we offer custom shearing and blanking services to your specified dimensions with ±0.2mm tolerance.

Q: How does this grade compare to silicon electrical steel?

A: Our pure iron offers higher saturation induction (2.15T vs 1.8T) and better formability, though with slightly higher core loss at high frequencies.

Q: What certifications support quality claims?

A: Production follows ISO 9001 standards, with material test reports provided for each batch.

Q: What is the minimum order quantity?

A: Standard MOQ is 5 metric tons, with trial quantities available for material testing purposes.

Ready to Optimize Your Electromagnetic Components?

Experience the difference of precision-engineered electromagnetic steel that enhances performance while reducing manufacturing complexity. Our technical team provides application-specific guidance on material selection and processing parameters.

Contact Shanxi Juli Run Technology today to request material samples or discuss custom specifications. All products are shipped with comprehensive technical documentation and international commercial terms.

Note: Specifications subject to technical improvements. Contact us for the latest material data sheets.

Send Inquiry to This Supplier

You May Also Like

-

Electrical Pure Iron CR Sheet With Superior Surface Quality for Precision StampingNegotiableMOQ: 1 Ton

-

High Purity Cold Rolled Electrical Pure Iron Sheet for Transformers and MotorsNegotiableMOQ: 1 Ton

-

Cold Rolled Thin Sheet Pure Iron DT4C for High-Frequency Electromagnetic ApplicationsNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Cold Rolled Thin Sheet DT4C 0.5mm Thick for High Magnetic Permeability ApplicationsNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Cold Rolled Thin Sheet 0.5mm DT4C for Magnetic Core ManufacturingNegotiableMOQ: 1 Ton

-

Electrical Pure Iron Cold Rolled Thin Sheet 0.5mm Thick With Low Iron Loss for Magnetic CircuitsNegotiableMOQ: 1 Ton

-

Industrial Pure Iron Cold Rolled Sheet DT4C With High Saturation Magnetic Flux Density for Motor CoresNegotiableMOQ: 1 Ton

-

High Magnetic Permeability Pure Iron Cold Rolled Thin Sheet DT4C Grade for TransformersNegotiableMOQ: 1 Ton

-

DT4C Cold Rolled Thin Sheet Pure Iron Material 0.5mm Thickness for Electrical EquipmentNegotiableMOQ: 1 Ton

-

DT4C Electromagnetic Pure Iron Cold Rolled Sheet/Plate for High Precision Magnetic ShieldingNegotiableMOQ: 1 Ton