High-Precision Crankshaft, Crankshaft Grinding & Machining Services

As a critical core component in internal combustion engines, crankshafts are essential for converting linear piston motion into rotational energy, directly determining the efficiency, stability, and service life of engines across automotive, marine, construction, and agricultural machinery fields. We specialize in professional crankshaft manufacturing, precision crankshaft grinding, and full-process crankshaft machining, delivering reliable, high-performance solutions tailored to global industrial demands.

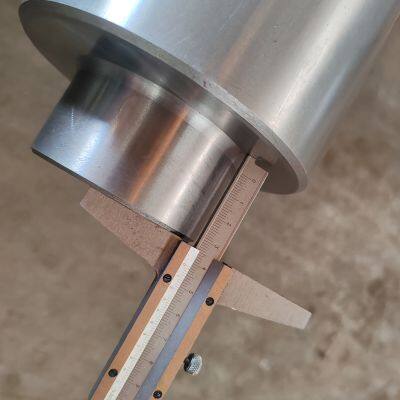

Our crankshaft machining process adheres to strict international standards, covering forging, turning, milling, heat treatment, and precision grinding to form a complete production closed loop. We use high-quality alloy steel and microalloyed steel materials, combined with advanced die forging technology, which increases material density by 15% and improves fatigue resistance significantly compared to traditional casting processes. The entire machining process is controlled by CNC equipment, ensuring crankshaft length up to 2000mm, journal roundness error within 0.003mm, and surface roughness reaching Ra0.4 for superior performance under high-load and high-speed operations.

Precision crankshaft grinding is the key to our product excellence. Equipped with advanced CBN crankshaft grinders featuring high-stability bearings and intelligent control systems, we achieve high-precision grinding of main journals and connecting rod journals. Our grinding technology minimizes thermal displacement, maintains consistent precision during long-term production, and ensures surface hardness up to 60HRC, balancing surface wear resistance with core toughness to extend crankshaft service life by more than twice that of standard products.

We offer flexible customization for crankshaft, crankshaft grinding, and crankshaft machining services, adapting to various engine models and industrial scenarios. From prototype development to mass production, we implement strict non-destructive testing and quality inspection procedures, ensuring a 99.9% product qualification rate. Our cost-effective solutions, timely delivery, and professional after-sales support have made us a trusted partner for global OEMs and aftermarket clients.

Choose our crankshaft machining and grinding services to get high-precision, durable components that enhance your equipment performance. We are committed to providing one-stop solutions that meet your specific needs, driving efficiency and reliability in your industrial operations.

Send Inquiry to This Supplier

You May Also Like

-

Mill Gear Shaft: High-Precision Durable Component for CEMEX Mexico Cement GrindingNegotiableMOQ: 1 Piece

-

ML Series Vertical Scraper Centrifugal Dehydrator-Luoyang Centrifuge ManufacturerNegotiableMOQ: 1 Unit

-

Hydraulic Station - Underground Hydraulic Station - Direct Sales of Hydraulic StationsNegotiableMOQ: 1 Unit

-

Sanyong Machinery Imported Gear Grinding Machine Shaft Processing Corrosion and Wear Resistance Heat Treatment Process OptimizationNegotiableMOQ: 1 Unit

-

Sanyong Large-Scale Machinery Precision Gears High Strength Load-Bearing Smooth and Reliable OperationNegotiableMOQ: 1 Unit

-

Large Ring Gear, Precise Dimension Control, Large Modulus, Sanyong Machinery, Manufacturer of Non-standard Customized Processing and ProductionNegotiableMOQ: 1 Unit

-

Sanyong Machinery: Manufacturer of Slewing Bearings for Rotary Tables, Processing According to Drawings, With High-precision Tooth Profile DesignNegotiableMOQ: 1 Unit

-

Segmented Gear Ring, Precision Large Gear, Arc Rack, Driving Wheel ManufacturerNegotiableMOQ: 1 Unit

-

Sanyong Machinery: Precision Large Gears, Empowering Industrial CoreNegotiableMOQ: 1 Unit

-

Sanyong Machinery: Precision Gear Shaft Machining via Horizontal LathesNegotiableMOQ: 1 Unit