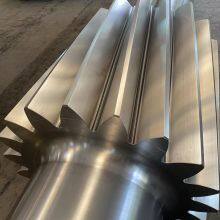

Mill Gear Shaft: High-Precision Durable Component for CEMEX Mexico Cement Grinding

In the high-stakes world of cement production, every component plays a pivotal role in ensuring uninterrupted operations and long-term profitability. The mill gear shaft, a core power transmission part for grinding equipment, is no exception—especially for CEMEX Mexico, a global leader in sustainable building materials. Our custom-manufactured mill gear shaft is specifically engineered to meet the rigorous demands of CEMEX Mexico’s cement grinding processes, delivering unmatched reliability, precision, and durability in harsh industrial environments.

Manufactured from premium alloy steel forgings, the gear shaft undergoes a series of strict thermal and mechanical treatments to optimize its performance. Through carburizing, quenching, and tempering, we achieve a perfect combination of surface hardness (HRC 58–62) and core toughness, enabling the shaft to resist wear, fatigue, and impact even under continuous heavy loads. Precision CNC machining, including hobbing and grinding, ensures tooth profile accuracy up to DIN 6 grade, promoting smooth meshing, low operational noise, and reduced vibration—key factors in extending mill service life.

We prioritize customization to align with CEMEX Mexico’s unique operational needs. Our engineering team collaborates closely with the client to analyze mill specifications, torque requirements, and performance goals, tailoring every detail—from shaft diameter to keyway design—to ensure a seamless fit and maximum power transmission efficiency. Rigorous quality control measures, such as magnetic particle inspection and ultrasonic testing, guarantee that each gear shaft meets or exceeds international industry standards, eliminating the risk of premature failure.

Since its deployment in CEMEX Mexico’s facilities, our mill gear shaft has delivered tangible benefits: reduced maintenance costs, extended service intervals, and improved grinding efficiency. By minimizing unplanned downtime and enhancing energy utilization, we help CEMEX Mexico maintain its competitive edge in the global cement market.

Our commitment to quality, customization, and engineering excellence makes us a trusted partner for heavy-duty industrial components. Whether for cement, mining, or metallurgy, we deliver solutions designed to perform in the world’s toughest environments—empowering our clients to operate more reliably and profitably.

Send Inquiry to This Supplier

You May Also Like

-

Mechanical Manufacturing, Welding Parts Processing, San Yong Machinery, High Precision, Complex Curved Surface Accurate FormingNegotiableMOQ: 1 Piece

-

Sanyong Large-Scale Machinery Precision Gears High Strength Load-Bearing Smooth and Reliable OperationNegotiableMOQ: 1 Unit

-

Large Ring Gear, Precise Dimension Control, Large Modulus, Sanyong Machinery, Manufacturer of Non-standard Customized Processing and ProductionNegotiableMOQ: 1 Unit

-

Sanyong Machinery: Manufacturer of Slewing Bearings for Rotary Tables, Processing According to Drawings, With High-precision Tooth Profile DesignNegotiableMOQ: 1 Unit

-

Segmented Gear Ring, Precision Large Gear, Arc Rack, Driving Wheel ManufacturerNegotiableMOQ: 1 Unit

-

Luoyang Sanyong Precision Forging Machine Crankshaft Connecting RodNegotiableMOQ: 1 Piece

-

Luoyang Sanyong Machinery Industry Provides a Wide Range of Rubber Roller Processing Specifications and Offers Professional Customization Services.NegotiableMOQ: 1 Piece

-

Sanyong Machinery: Precision Large Gears, Empowering Industrial CoreNegotiableMOQ: 1 Unit

-

Luoyang Sanyong 8m Gear Hobbing Machine: The Epitome of High-Precision Machining for Large GearsNegotiableMOQ: 1 Unit

-

Luoyang Sanyong: Leading Precision Deep-Hole Honing for Superior Component PerformanceNegotiableMOQ: 1 Unit