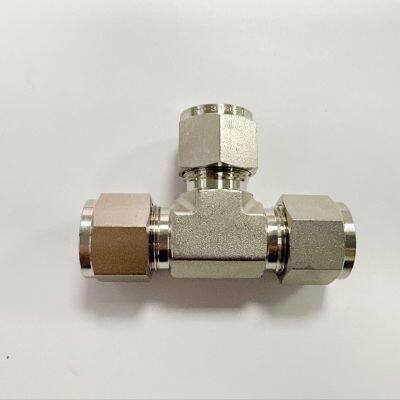

ASME BPE Compliant Stainless Steel Tee Fitting, Electropolished Surface, Biopharma Fluid Transfer

Shanghai Quanbao Electronic Materials Technology Co., Ltd., a specialized manufacturer based in Shanghai, China, presents this precision-engineered ASME BPE compliant tee fitting for critical bioprocessing applications. Designed to meet stringent hygienic requirements, our electropolished stainless steel tee ensures exceptional purity control in pharmaceutical and biotech fluid transfer systems. This product demonstrates our commitment to delivering reliable components that maintain process integrity while reducing contamination risks.

The tee fitting features advanced surface technology and rigorous manufacturing standards essential for maintaining sterile conditions in sensitive operations. With its optimized flow characteristics and durable construction, it provides long-term performance in demanding environments such as vaccine production and cell culture media transfer. Our solution addresses the critical need for consistent product quality throughout biomanufacturing workflows.

Core Technical Specifications:

| Parameter | Specification |

|---|---|

| Primary Material | 316L Stainless Steel |

| Surface Roughness (Ra) | ≤ 0.38 μm (15 μin) after electropolishing |

| Pressure Rating | 10 bar @ 20°C (145 psi) |

| Temperature Range | -20°C to 150°C (-4°F to 302°F) |

| Connection Standard | Tri-Clamp (ISO 2852/ASME B16.9) |

| Dimensional Standard | ASME BPE-2022 SD-03 |

Key Performance Advantages:

Enhanced Cleanability: Electropolished surface minimizes bacterial adhesion and facilitates efficient CIP/SIP cycles, reducing downtime between batches

Corrosion Resistance: High chromium-nickel composition withstands aggressive cleaning agents and process media

Flow Optimization: Smooth internal contours prevent turbulence and particle entrapment for consistent fluid dynamics

Validation Support: Full traceability documentation available for quality assurance protocols

For bioprocess engineers, this tee fitting delivers measurable benefits including reduced risk of cross-contamination, extended service life through superior material integrity, and simplified maintenance due to standardized connections. The optimized design prevents dead zones where media could accumulate, directly supporting product yield and process efficiency in applications such as:

Buffer and media preparation systems

Fermentation and bioreactor piping networks

Purification skids and filtration assemblies

Fill-finish operations and product transfer lines

Shanghai Quanbao leverages its manufacturing expertise in Shanghai – China's biopharma hub – to deliver components that meet global quality expectations. Our production facility maintains strict process controls aligned with industry best practices, ensuring every fitting meets dimensional and surface finish requirements. With over a decade of specialization in high-purity fluid components, we provide technical support throughout equipment integration and validation phases.

Frequently Asked Questions:

Q: What documentation accompanies these fittings?

A: Each shipment includes material certifications (MTRs), surface roughness reports, and certificates of compliance. Additional validation packages are available upon request.Q: Are custom angles or branch sizes available?

A: Yes, we offer customized configurations including different branch orientations and non-standard diameters for specialized applications.Q: How do these fittings perform with high-viscosity fluids?

A: The optimized internal geometry minimizes pressure drop and prevents stagnation even with viscous media like cell cultures or protein solutions.Q: What gasket materials are compatible?

A: Standard EPDM and FKM gaskets are recommended. Alternative materials such as PTFE or silicone can be accommodated based on process requirements.Q: Can these fittings be integrated with existing DIN-standard systems?

A: Yes, adapters for DIN 11851 and other international standards are optionally available to ensure compatibility.Q: What is the lead time for urgent projects?

A: Standard sizes are typically shipped within 2 weeks. Expedited manufacturing options can reduce lead times for critical project timelines.

As a Shanghai-based manufacturer with extensive experience in bioprocessing components, Shanghai Quanbao ensures reliable supply chain solutions for global pharmaceutical partners. Our tee fittings undergo multiple quality checks including dimensional verification, surface profilometry, and visual inspection under controlled lighting. Partner with us for components that enhance system reliability while maintaining compliance with current good manufacturing practices (cGMP).

Contact our technical team today to discuss your specific application requirements or request validation documentation. We offer comprehensive support from component selection through installation validation to ensure seamless integration into your critical processes.

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Male to Female Adapter Connector for Industrial PipingNegotiableMOQ: 500 Pieces

-

Heavy Duty Stainless Steel Flange Pipe Connector for Female Thread ApplicationsNegotiableMOQ: 500 Pieces

-

304/316 Stainless Steel Quicklock Snap-in Male Female Fittings With Insulated ThroatNegotiableMOQ: 500 Pieces

-

Marine Grade Stainless Steel 304/316 Ferrule Tube Fitting Bulkhead Female ConnectorNegotiableMOQ: 500 Pieces

-

N Type Female Test Straight Adapter Connector With Stainless Steel Surface PassivationNegotiableMOQ: 500 Pieces

-

Copper Brass Stainless Steel Camlock Quick Coupling Male Female Connector for Industrial UseNegotiableMOQ: 500 Pieces

-

Reducing Hex Coupling for Hydraulic Systems in Construction and Agricultural Machinery ApplicationsNegotiableMOQ: 10 Pieces

-

Durable Reducing Hex Coupling With Leak-Proof Design for Enhanced Flow Efficiency in Fluid TransferNegotiableMOQ: 10 Pieces

-

Stainless Steel Female Thread to Double Ferrule Straight Union, NPT/BSPT/BSPP, High-Pressure ConnectionNegotiableMOQ: 10 Pieces

-

Stainless Steel Female Thread to Double Ferrule Straight Fitting, Customizable Sizes, Safe for High-Pressure SystemsNegotiableMOQ: 10 Pieces