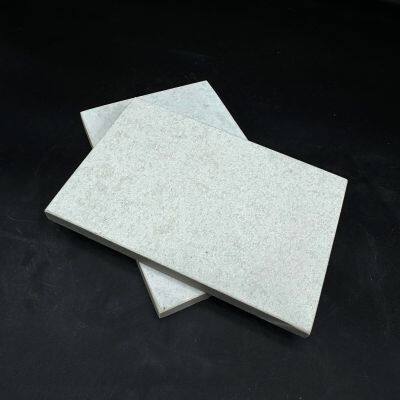

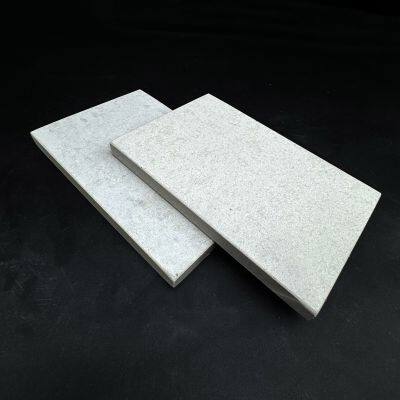

Premium Calcium Silicate Board for High-Temperature Insulation & Fireproofing, 1200°C Resistance

As a leading manufacturer certified with ISO9001 and ISO14000, Shanxi Pano Building Materials Co., Ltd leverages 30,000-50,000 sqm of advanced production facilities to deliver premium calcium silicate boards engineered for extreme thermal protection. Since 2021, our solutions have empowered industrial clients across North America, Europe, and Asia to achieve safer, more efficient high-temperature operations. This board withstands continuous exposure to 1200°C while maintaining structural integrity – making it indispensable for critical fireproofing and insulation applications.

Core Advantages & Technical Specifications:

- Unmatched Thermal Stability: Low thermal conductivity (0.05-0.07 W/m·K) minimizes heat transfer, reducing energy costs by up to 30% in kilns, boilers, and pipelines.

- Superior Fire Resistance: Non-combustible (A1-rated) composition prevents flame spread and toxic smoke emission, meeting stringent safety codes for commercial and industrial structures.

- Mechanical Durability: High compressive strength (≥1.2 MPa) and minimal shrinkage at 1000°C ensure long-term reliability in vibrating environments.

- Chemical Inertness: Resists corrosion from oils, alkalis, and weak acids, extending service life in aggressive industrial settings.

Key physical properties include:

| Parameter | Value |

|---|---|

| Density | 220-280 kg/m³ |

| Thermal Conductivity (at 600°C) | 0.07 W/m·K |

| Linear Shrinkage (1000°C × 24h) | ≤2% |

| Compressive Strength | ≥1.2 MPa |

Applications span diverse sectors:

- Industrial: Insulation for steel ladles, reactors, and exhaust systems

- Construction: Fire-rated partitions, elevator shafts, and HVAC duct enclosures

- Energy: Backup protection for LNG tanks and power plant equipment

Backed by an annual export volume of US$2.5-5 million and a 200-strong technical team, we ensure consistent quality through automated production lines. Our boards ship globally via ports in Tianjin and Qingdao, with tailored thicknesses (25-100mm) and sizes to fit project-specific requirements. Partner with us to enhance operational safety while reducing maintenance costs – request a sample today to validate performance in your application.

Frequently Asked Questions (FAQ):

Q1: What is the maximum service temperature for this board?

A: The board maintains structural stability at continuous temperatures up to 1200°C (2192°F), with short-term tolerance to 1300°C.

Q2: Can it be cut or shaped onsite?

A: Yes, standard woodworking tools easily cut the material. Custom pre-fabricated shapes are also available upon request.

Q3: Does it contain asbestos or other hazardous materials?

A: No. Our boards are asbestos-free and comply with international health and safety regulations.

Q4: What certifications support the fireproofing claims?

A: While specific fire test reports vary by market, our ISO-certified manufacturing process ensures consistent adherence to non-combustible (A1) standards per EN 13501-1.

Q5: How does moisture affect performance?

A: The closed-cell structure resists water absorption (

Q6: What is the typical lead time for orders?

A: Standard specifications ship within 14 days. Customized orders may require 3-4 weeks depending on complexity.

Send Inquiry to This Supplier

You May Also Like

-

Non-Asbestos Calcium Silicate Board for Ceiling & Wall Applications in Industrial and Civil ConstructionNegotiableMOQ: 100 Pieces

-

A1 Fire-Rated Calcium Silicate Board for Partition Walls and Suspended Ceilings in Public SpacesNegotiableMOQ: 100 Pieces

-

Low Thermal Conductivity Calcium Silicate Board for Enhanced Thermal Insulation PerformanceNegotiableMOQ: 100 Pieces

-

Moisture-Resistant Calcium Silicate Board Suitable for High Humidity Environments and Clean RoomsNegotiableMOQ: 100 Pieces

-

Durable Calcium Silicate Board 2440x1220mm for Industrial Furnaces and High-Temperature ApplicationsNegotiableMOQ: 100 Pieces

-

High Density Calcium Silicate Board 10-15mm Thickness Thermal Insulation Wall PanelNegotiableMOQ: 500 Pieces

-

Precision Cut Calcium Silicate Sheets Smooth Surface for Interior Decoration 9mm-20mmNegotiableMOQ: 500 Pieces

-

A1 Fire Rated Calcium Silicate Board Moisture Resistant for Commercial BuildingsNegotiableMOQ: 500 Pieces

-

Non-Combustible Calcium Silicate Wall Cladding Low Thermal Conductivity 2400x1200mmNegotiableMOQ: 500 Pieces

-

Calcium Silicate Insulation Board Chemical Resistant for Clean Rooms and LaboratoriesNegotiableMOQ: 500 Pieces