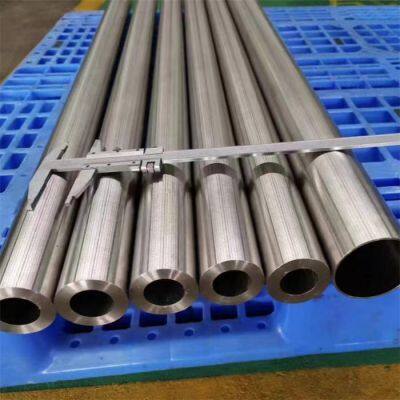

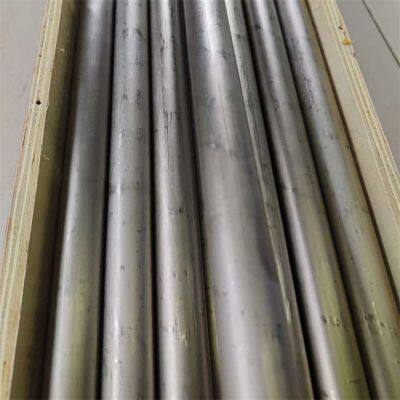

High-Strength Corrosion-Resistant Titanium Alloy Tube for Enhanced Performance

Engineered for extreme environments, our titanium alloy tubing delivers unparalleled corrosion resistance and structural integrity. These seamless tubes combine lightweight advantages with exceptional strength-to-weight ratios, making them ideal for mission-critical applications where failure is not an option. Through advanced metallurgical processes, we achieve consistent material properties that outperform conventional stainless steel alternatives.

Core Performance Advantages:

Superior corrosion resistance in acidic, saline, and high-temperature environments

Excellent fatigue strength and fracture toughness

Biocompatible properties suitable for medical applications

Non-magnetic characteristics for specialized equipment

Technical Specifications:

Custom dimensional configurations are available to meet specific project requirements. Our manufacturing capabilities include cold-drawing and pilgering processes that maintain precise dimensional tolerances of ±0.05mm. All products undergo rigorous non-destructive testing including ultrasonic examination and eddy current testing to ensure defect-free performance.

Industry Applications:

Aerospace: Hydraulic systems, engine components

Chemical Processing: Heat exchangers, reactor tubing

Marine Engineering: Seawater piping systems

Medical: Surgical instruments, implant devices

Backed by our ISO9001 certified quality management system, we guarantee traceability from raw material to finished product. Jiangsu Zhonggongte Metallurgical Technology maintains an annual export volume exceeding $100 million, with logistics support through Shanghai and Tianjin ports for efficient global distribution.

Frequently Asked Questions:

Q: What is the lead time for custom orders?

A: Standard production lead time is 4-6 weeks, with expedited options available for urgent requirements.

Q: Do you provide material certification?

A: All shipments include mill test certificates with full chemical composition and mechanical properties.

Q: What packaging standards do you use?

A: Tubes are protected with plastic end caps and packed in wooden crates with waterproof wrapping.

Q: Can you match specific industry standards?

A: We regularly produce to ASTM B338, AMS 4928, and DIN 3.7165 specifications.

Q: What is your minimum order quantity?

A: MOQ starts at 100kg with no maximum limit for bulk orders.

Contact our technical team today for project-specific solutions and volume pricing. With established overseas offices and extensive experience serving global markets, we provide reliable supply chain solutions for your most demanding engineering challenges.

Send Inquiry to This Supplier

You May Also Like

-

Titanium Alloy Plate Ta2 in Custom Sizes and Thicknesses for Precision Engineering ProjectsNegotiableMOQ: 1 Ton

-

Lightweight and Corrosion-Resistant Titanium Alloy Bar TC4 for Marine and Offshore EquipmentNegotiableMOQ: 1 Ton

-

Aerospace Application Titanium Alloy Bar TC11, Compatible With Aircraft Frames and Satellite ComponentsNegotiableMOQ: 1 Ton

-

Custom Size Titanium Alloy Bar TC4, Diameter Range 10-150mm for Precision Machining and Engineering ProjectsNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Bar TC4 for Automotive Engine Parts and Industrial Machinery FabricationNegotiableMOQ: 1 Ton

-

Medical Grade Titanium Alloy Bar TC11 for Orthopedic Implants and Surgical Instrument ManufacturingNegotiableMOQ: 1 Ton

-

Industrial Pure Titanium Plate Ta2 With Excellent Formability and Weldability for Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

Precision Titanium Alloy Bar TA15 in Various Diameters (5mm-200mm) for Industrial MachiningNegotiableMOQ: 50 Kilograms

-

Custom Precision Titanium Alloy Bar Stellite6 Factory Marine Corrosion Resistant Titanium Rod SupplierNegotiableMOQ: 50 Kilograms

-

High-Strength Titanium Alloy Bar Stellite12 With Superior Corrosion Resistance for Demanding EnvironmentsNegotiableMOQ: 50 Kilograms