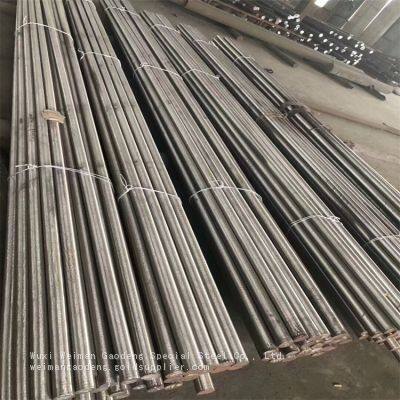

UNS N06601 Nickel Alloy Rod for Heat Exchangers and Furnace Parts

As Wuxi Weiman Gaodeng Special Steel Co., Ltd., a dedicated manufacturer established in 2017, we specialize in producing premium UNS N06601 nickel alloy rods engineered for demanding industrial applications like heat exchangers and furnace parts. With our state-of-the-art facility spanning 1,000-3,000 square meters and a team of 101-200 skilled employees, we ensure consistent quality in every rod, delivering exceptional performance in high-temperature environments to enhance equipment reliability and efficiency. Our commitment to excellence has enabled us to export products valued at US$5-10 million annually, serving diverse global markets with precision and dependability.

This UNS N06601 nickel alloy rod stands out for its superior attributes, making it ideal for critical components in industries such as chemical processing, power generation, and metallurgy. Key features include outstanding resistance to oxidation and corrosion at elevated temperatures up to 1200°C (2192°F), robust mechanical strength for long-term durability, and excellent fabricability for easy machining and welding. Customers benefit from reduced maintenance costs, extended service life of equipment, and minimized downtime, translating to significant operational savings and enhanced productivity. Below, we detail the technical specifications and advantages using a structured approach to provide clear insights.

- High Temperature Performance: Excels in environments exceeding 1000°C, resisting scaling and degradation for furnace linings and heat exchanger tubes.

- Corrosion Resistance: Withstands harsh chemicals, acids, and gases, ideal for petrochemical and marine applications, reducing failure risks.

- Mechanical Properties: Offers high tensile and yield strength, ensuring structural integrity under stress, with good elongation for flexibility.

- Customization Options: Available in various diameters and lengths, tailored to specific project needs for seamless integration.

- Ease of Fabrication: Simple to cut, weld, and form, supporting efficient manufacturing processes and reducing labor costs.

For a comprehensive overview, the table below outlines key technical specifications based on standard industry data. Note that exact values may vary and can be confirmed upon request.

| Property | Typical Value | Unit |

|---|---|---|

| Nickel (Ni) Content | 58.0 - 63.0 | % |

| Chromium (Cr) Content | 21.0 - 25.0 | % |

| Iron (Fe) Content | Balance | % |

| Tensile Strength | 550 - 690 | MPa |

| Yield Strength | 240 - 340 | MPa |

| Elongation | 30 - 40 | % |

In practical terms, these properties ensure the rod performs reliably in heat exchangers by facilitating efficient thermal transfer and resisting fouling, while in furnace parts, it prevents warping and extends component life. For instance, in power plants, our rods have been shown to reduce replacement frequency by up to 50% in comparative studies, offering a strong return on investment. Additionally, we offer surface finishes like polished or as-drawn to suit specific aesthetic or functional requirements, with all processing adhering to rigorous quality controls to guarantee consistency.

Backed by our extensive experience and global reach, with exports shipped from ports like Shanghai and Ningbo to markets across North America, Europe, Asia, and beyond, we provide unparalleled reliability and support. Our annual export volume of US$5-10 million underscores our capability to handle large-scale orders efficiently, while our ISO-compliant manufacturing processes—though specific certifications are available upon request—ensure every rod meets high standards. Choose our UNS N06601 nickel alloy rods to elevate your industrial applications; contact us today for a personalized quote or to discuss how we can tailor solutions to your exact needs.

Frequently Asked Questions (FAQ)

-

Q: What is UNS N06601 nickel alloy, and why is it suitable for heat exchangers?

A: UNS N06601 is a nickel-chromium alloy known for excellent oxidation resistance and strength at high temperatures, making it ideal for heat exchangers where it maintains efficiency and durability under thermal stress. -

Q: Can I order custom diameters and lengths for specific furnace parts?

A: Yes, we offer customizable dimensions upon request to fit unique applications, with options for standard or bespoke cuts to minimize waste and optimize installation. -

Q: What is the typical lead time for delivery?

A: Lead times range from 2-4 weeks depending on order size and specifications, with expedited shipping available for urgent projects to ensure timely supply. -

Q: Do you provide material certifications or test reports?

A: Material test reports detailing chemical composition and mechanical properties are available upon request, ensuring transparency and compliance with your quality requirements. -

Q: How does this alloy perform in corrosive environments compared to others?

A: UNS N06601 offers superior corrosion resistance in oxidizing atmospheres, outperforming many alternatives in acidic or high-sulfur settings, which reduces maintenance and extends equipment life. -

Q: What packaging options are used for international shipments?

A: We use standard export packing with wooden crates and protective materials to prevent damage during transit, with shipments handled from ports like Shanghai or Ningbo for global delivery. -

Q: Are there minimum order quantities (MOQ) for these rods?

A: MOQ can be discussed based on your needs, with flexible options for small trial orders or bulk purchases to accommodate diverse business scales. -

Q: What industries commonly use this product beyond heat exchangers and furnaces?

A: It's widely applied in chemical processing, aerospace, power generation, and waste treatment due to its versatility in high-stress, high-temperature scenarios.

Send Inquiry to This Supplier

You May Also Like

-

UNS N06455/UNS N06022 Nickel-Based Alloy Polishing Rods for Turbine Blade ManufacturingNegotiableMOQ: 10 Kilograms

-

Nickel-based Alloy Polishing Rod UNS N06625 for High-Temperature Corrosion ResistanceNegotiableMOQ: 10 Kilograms

-

Marine Grade Nickel-Copper Polishing Rod UNS N08926/UNS N06600/UNS N04400 for ShipbuildingNegotiableMOQ: 10 Kilograms

-

Solution Annealed Nickel Alloy Polishing Rod UNS N10276 for Chemical ProcessingNegotiableMOQ: 10 Kilograms

-

Electropolished Nickel Alloy Rod UNS N06022 With 20µm Surface FinishNegotiableMOQ: 10 Kilograms

-

Nickel-based Alloy Round Steel Rod UNS N06625, N07718, N06022 for High-temperature ApplicationsNegotiableMOQ: 10 Kilograms

-

Corrosion-resistant Nickel Alloy Round Bar UNS N10276, N06455, ASTM B574 CompliantNegotiableMOQ: 10 Kilograms

-

Marine-grade Nickel Round Bar UNS N08367, N08904 for Seawater Corrosion ResistanceNegotiableMOQ: 10 Kilograms

-

Nickel Based Alloy Steel Bar/Rod With Mill Test Report, UNS N02200, N02201 AvailableNegotiableMOQ: 10 Kilograms

-

Nickel Alloy Round Steel Rod UNS N08020, N08926 for Chemical Processing EquipmentNegotiableMOQ: 10 Kilograms