Precision Ground Nickel Alloy Polishing Rod UNS N07718 With 0.005mm Tolerance

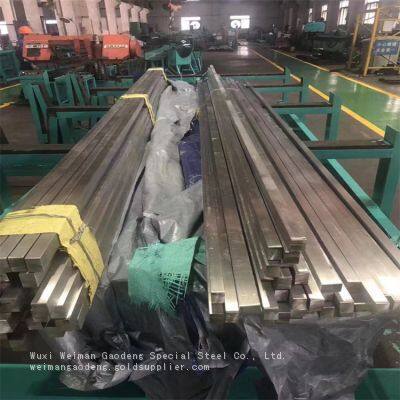

As a dedicated manufacturer since 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. proudly introduces our precision ground nickel alloy polishing rod made from UNS N07718, featuring an ultra-tight tolerance of 0.005mm. With our 1,000-3,000 square meter factory and over 100 employees, we specialize in producing high-quality rods that meet exacting industrial standards, ensuring reliability for demanding applications. Exported globally to markets including North America, Europe, and Asia through ports like Shanghai and Ningbo, our products offer unmatched precision and durability, backed by an annual export value of US$5-10 million. Trust us for consistent quality and efficient solutions tailored to your needs.

Our precision ground rods are crafted for industries requiring superior accuracy and performance. The UNS N07718 nickel alloy provides exceptional properties:

- High Strength and Corrosion Resistance: Ideal for harsh environments like aerospace and chemical processing, where it withstands extreme temperatures and corrosive substances, reducing maintenance costs.

- Precision Grinding: Achieves a smooth, polished surface with minimal roughness, ensuring seamless integration and reducing friction in assemblies.

- Tight Tolerance: The 0.005mm tolerance guarantees exact dimensional accuracy, critical for applications like valve components or precision instruments, minimizing errors and enhancing efficiency.

Key technical specifications include:

| Parameter | Value | Benefits |

|---|---|---|

| Material Composition | Nickel Alloy UNS N07718 | Offers high-temperature stability and corrosion resistance, extending product lifespan. |

| Tolerance | ±0.005mm | Ensures precise fit in critical assemblies, improving overall system reliability. |

| Surface Roughness (Ra) | ≤ 0.2μm (after polishing) | Reduces wear and tear, lowering operational costs. |

| Diameter Range | Customizable (e.g., 5mm-100mm) | Flexible sizing to suit diverse applications, from small tools to large machinery. |

| Length Options | Available upon request (up to 6000mm) | Adaptable to specific project requirements, saving time on customization. |

Advantages for your business include reduced downtime due to the rod's durability, cost savings from extended service life, and enhanced productivity through easy installation. For instance, in aerospace, this rod ensures reliable performance in engine components, while in chemical plants, it resists degradation from acids. Our commitment to quality means each rod undergoes rigorous inspection, delivering consistent results that support your operational goals.

With our established presence since 2017 and a team of 101-200 professionals, we have shipped products to over 14 global markets, including Oceania, Africa, and Europe, via key ports like Suzhou and Lianyungang. This extensive export experience, coupled with a US$5-10 million annual value, ensures dependable delivery and responsive support. Our precision rods are designed to outperform in demanding scenarios—contact us today to discuss your specifications and benefit from our expertise in high-tolerance solutions.

Frequently Asked Questions:

- Q: What are the common applications for UNS N07718 rods? A: They are widely used in aerospace for engine parts, chemical processing for reactor components, and oil and gas for valves, due to their high strength and corrosion resistance.

- Q: How is the 0.005mm tolerance achieved? A: Through advanced precision grinding techniques in our facility, ensuring consistent dimensional accuracy for reliable performance in tight-tolerance assemblies.

- Q: Can I customize the dimensions of the rod? A: Yes, diameter and length are customizable upon request to fit your specific project needs, with options available for various industrial standards.

- Q: What makes UNS N07718 alloy suitable for high-temperature environments? A: Its nickel-chromium composition provides excellent thermal stability and oxidation resistance, making it ideal for applications up to high temperatures without degradation.

- Q: Are there certifications available for these rods? A: Certifications can be provided upon request, tailored to meet regional or industry-specific requirements.

- Q: What is the typical lead time for orders? A: Lead times vary based on customization but are generally optimized for efficiency, with expedited options available to ensure timely delivery.

- Q: How does the polished surface benefit mechanical assemblies? A: It reduces friction and wear, leading to smoother operation and longer component life in moving parts.

- Q: What packaging and shipping options are offered? A: Rods are securely packaged to prevent damage, with shipping from ports like Ningbo and Shanghai to global destinations, ensuring safe transit.

Send Inquiry to This Supplier

You May Also Like

-

Marine Grade Nickel-Copper Polishing Rod UNS N08926/UNS N06600/UNS N04400 for ShipbuildingNegotiableMOQ: 10 Kilograms

-

Solution Annealed Nickel Alloy Polishing Rod UNS N10276 for Chemical ProcessingNegotiableMOQ: 10 Kilograms

-

Electropolished Nickel Alloy Rod UNS N06022 With 20µm Surface FinishNegotiableMOQ: 10 Kilograms

-

Nickel-based Alloy Round Steel Rod UNS N06625, N07718, N06022 for High-temperature ApplicationsNegotiableMOQ: 10 Kilograms

-

Corrosion-resistant Nickel Alloy Round Bar UNS N10276, N06455, ASTM B574 CompliantNegotiableMOQ: 10 Kilograms

-

Marine-grade Nickel Round Bar UNS N08367, N08904 for Seawater Corrosion ResistanceNegotiableMOQ: 10 Kilograms

-

Nickel Based Alloy Steel Bar/Rod With Mill Test Report, UNS N02200, N02201 AvailableNegotiableMOQ: 10 Kilograms

-

Nickel Alloy Round Steel Rod UNS N08020, N08926 for Chemical Processing EquipmentNegotiableMOQ: 10 Kilograms

-

Precision-ground Nickel Round Rod UNS N06030, N08825, 10-500mm Diameter Tolerance ±0.05mmNegotiableMOQ: 10 Kilograms

-

ASTM B166 Compliant Nickel Round Bar UNS N04400, N05500, 1-12 Inch DiametersNegotiableMOQ: 10 Kilograms