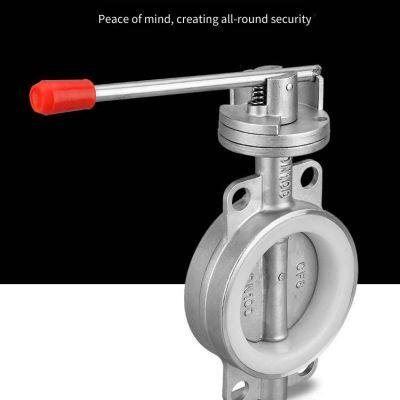

Stainless Steel Precision Casting Industrial Grade Wafer Type Four-eared Butterfly Valve D71x Straight Rod Handle Adjustable Control Valve

D71X is the model code of the wafer soft-sealed butterfly valve. The butterfly plate of this butterfly valve is installed in the diameter direction of the pipeline. Inside the cylindrical passage of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, with a rotation angle between 0° and 90°. When it rotates to 90°, the valve is in the fully open state.

High-performance soft-sealed butterfly valve,

It is characterized in that: the valve seat sealing ring is composed of a soft T-shaped sealing ring with multiple layers of stainless steel sheets on both sides.

The sealing surfaces of the valve plate and the valve seat are in an oblique cone structure. Heat-resistant and corrosion-resistant alloy materials are overlaid on the oblique cone surface of the valve plate. It has a structure where the spring fixed between the adjusting ring pressure plates is assembled with the adjusting bolts on the pressure plates. This structure effectively compensates for the tolerance zone between the bushing and the valve body and the elastic deformation of the valve stem under the medium pressure, and solves the sealing problem existing in the bidirectional interchangeable medium transportation process of the valve.

Using a sealing ring composed of multiple layers of stainless steel sheets on both sides of the soft T-type, it has the dual advantages of metal hard sealing and soft sealing. It has zero-leakage sealing performance under both low and high temperatures. Tests have proven that in the forward flow state (the medium flow direction is the same as the rotation direction of the butterfly plate), the pressure on the sealing surface is generated by the torque of the transmission device and the action of the medium pressure on the valve plate. When the forward medium pressure increases, the oblique cone surface of the valve plate and the valve seat sealing surface are squeezed more tightly, and the sealing effect is better.

In the reverse flow state, the sealing between the valve plate and the valve seat relies on the torque of the driving device to press the valve plate against the valve seat. As the reverse medium pressure increases, when the unit positive pressure between the valve plate and the valve seat is less than the medium pressure, the deformation energy stored by the spring of the adjusting ring after being loaded compensates for the pressing force on the sealing surfaces of the valve plate and the valve seat, playing an automatic compensation role.

2. Characteristics of the D71X wafer soft-sealed butterfly valve:

1. This valve adopts a double-eccentric structure, with a sealing function that becomes tighter as it closes, and the sealing performance is reliable.

2. The sealing pair materials are selected from the pairing of stainless steel and nitrile oil-resistant rubber, with a long service life.

3. The rubber sealing ring can be located either on the valve body or on the butterfly plate, which can be suitable for media with different characteristics for users to choose.

4. The butterfly plate adopts a frame structure, with high strength, a large flow area, and small flow resistance.

5. The overall baking finish can effectively prevent corrosion. As long as the sealing material of the sealing valve seat is replaced, it can be used for different media.

6. This valve has a two-way sealing function. When installing, it is not controlled by the medium flow direction and is not affected by the spatial position. It can be installed in any direction.

7. This valve has a unique structure, and is flexible, labor-saving and convenient to operate.

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Male and Female Threaded Union, Cast Pipe Fittings With Male and Female Threads UnionsUS$ 3.23 - 3.85MOQ: 10 Sets

-

Ibc Powder Butterfly Valve, Discharge Valve at the Bottom of Turnover Silo, Large Diameter Butterfly Valve, Sanitary Butterfly Valve, Center Clamp Butterfly ValveUS$ 140.77 - 153.85MOQ: 1 Piece

-

316 Stainless Steel Fixed Cleaning Ball Spray Nozzle Cleaning BallUS$ 5.38MOQ: 10 Pieces

-

304 Stainless Steel Baijiu Glass, Small Stemmed Glass, Thickened Stainless Steel Wine Cup, Shatterproof DrinkwareUS$ 40MOQ: 1 Set

-

13sf Heavy-duty Double-pin Round Clamp, 304 Stainless Steel Quick-installation Connector, Universal ClampUS$ 2.31 - 2.77MOQ: 1 Piece

-

Factory Direct Supply 304, 316l 360-degree Rotating Cleaning Balls, Spray Balls, Rapid Cleaning Dn50 my Dream FieldUS$ 6.62 - 7.38MOQ: 1 Piece

-

Factory Direct Sale 304 316l Stainless Steel Rotary Spray Ball, Cleaning Ball With 360-degree Rotation, Dn25 my Dream FieldUS$ 6.62 - 6.92MOQ: 1 Piece

-

Stainless Steel 304 Quick - Install Spraying Ball 360 - Degree Rotating Tank Cleaner Universal Threaded Pin - Type Double Chuck Cleaning Ball Dn25US$ 6.46 - 7.38MOQ: 1 Piece

-

Wenzhou my Dream Field Hygienic Quick - Install Rotary Cleaning Ball 360 - Degree Rotary Spraying Ball Dn50US$ 6.62 - 7.38MOQ: 1 Piece

-

316l Stainless Steel Rotating Spray Ball With Quick - Installing Threaded Pin, Dn10 - 50 Cleaning Ball, my Dream FieldUS$ 6.46 - 7.38MOQ: 1 Piece