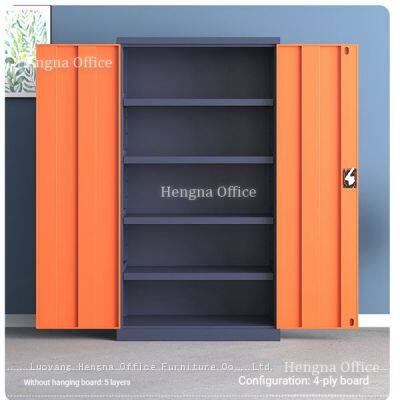

Orange Metal Workshop Storage Locker TC-W207 for 5S Lean Management With Adjustable Shelves &Parts Bins |1800mm High for Factory Assembly Line

The TC-W207 Metal Workshop Storage Locker is engineered as a foundational tool for Lean Manufacturing, specifically designed to optimize the workflow of high-speed factory assembly environments.

The 5S Lean Management Powerhouse

The TC-W207 is not merely a storage unit; it is a discipline enforcer. Built to support 5S methodology, this locker helps factory managers implement a culture of efficiency:

Sort (Seiri): Clear out the clutter by providing designated zones for essential assembly tools.

Set in Order (Seiton): With its adjustable shelves and integrated parts bins, every component has a specific home, reducing "search time" to zero.

Shine (Seiso): The raised base and easy-clean electrostatic finish ensure the workstation remains debris-free.

Standardize (Seiketsu): Deploying TC-W207 units across the entire assembly line creates a uniform, professional look that simplifies training.

Sustain (Shitsuke): Robust construction encourages long-term adherence to organizational standards.

Industrial Specification Matrix: TC-W207

| Feature Category | Technical Specification | Assembly Line Benefit |

| Model Number | TC-W207 | Systematic Inventory Tracking |

| Height | 1800mm (Full-Height) | Maximizes vertical space without increasing footprint |

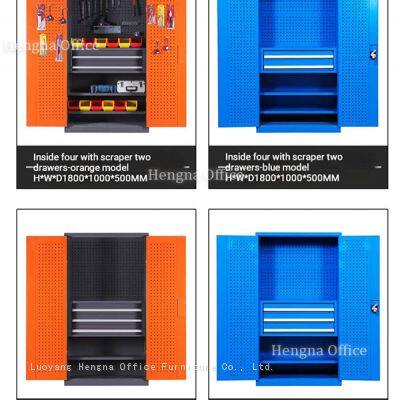

| Storage Type | Shelves + Parts Bins | Hybrid storage for tools and small fasteners |

| Adjustment | Screw-less Card-slot Type | Rapid reconfiguration for different product runs |

| Security | Reinforced Lock Bars | Prevents unauthorized tool removal or "borrowing" |

| Load Rating | Industrial Grade (Reinforced) | Safe storage for heavy jigs and fixtures |

| Footprint | 1000mm x 500mm | Ideal for placement at the end of assembly cells |

Engineered for the Assembly Cell

Factory floors are dynamic environments. The TC-W207 adapts to these changes through its high-density storage logic.

Vertical Space Optimization

Standing at 1800mm high, the TC-W207 takes advantage of verticality. In crowded assembly lines where floor space is at a premium, this locker allows you to store a vast array of assembly jigs, power tools, and raw materials within a compact 0.5 square meter footprint.

Modular "No-Tool" Adjustability

One of the standout features of the TC-W207 is its built-in adjustable laminate system. Using a card-slot design, shelves can be moved up or down without the need for additional tools. This is crucial for factory lines that undergo frequent "Changeovers"—allowing the locker to be reconfigured from storing tall pneumatic hoses to flat electronic components in seconds.

Small Parts Management (The Bin System)

Assembly lines live and die by the availability of small parts like nuts, bolts, and clips. The TC-W207 includes a series of back-mounted parts bins. These bins are removable, allowing workers to take a specific bin directly to the assembly bench and return it to the locker at the end of the shift, ensuring zero part-mix-ups.

Durability for 24/7 Operations

Manufacturing plants often run on multiple shifts. The TC-W207 is built for this non-stop usage:

Heavy-Gauge Steel: Resists warping under the weight of heavy metal components.

Full-Length Stiffeners: The doors feature internal reinforcement to prevent "door-wobble" even after thousands of cycles.

Anti-Rust Treatment: The industrial-grade powder coating is resistant to the oils and coolants typically found in machining and assembly areas.

Safety and Ergonomics

Employee safety is paramount. The TC-W207 features recessed handles and smooth edges to prevent snagging on work uniforms or causing injuries in tight aisles. The "linkage lock" ensures that all doors are flush and secure, maintaining clear pathways for forklifts and automated guided vehicles (AGVs).

Frequently Asked Questions (FAQ)

Q1: How much weight can each shelf realistically hold in a factory setting?

A: Each shelf in the TC-W207 is reinforced with a center support rib, allowing it to hold up to 100kg-120kg of evenly distributed weight. This makes it suitable for heavy copper wiring spools or metal casting jigs.

Q2: Can we customize the color of the bins to match our factory’s color-coding system?

A: Yes. While standard bins are blue, we offer red, yellow, and green bins for bulk orders. This is a common request for factories using "Visual Management" to separate "Pass" parts from "Reject" parts.

Q3: Is the TC-W207 shipped assembled or flat-packed?

A: We offer both options. Most factory clients prefer the fully welded version for immediate deployment and maximum structural integrity. However, for international shipments to reduce freight costs, our knock-down (KD) version is designed for assembly in under 20 minutes with a single wrench.

Send Inquiry to This Supplier

You May Also Like

-

Tapered Bit Storage Organizer CT-B921 for Anti-Collision Safety |Modular Suspension Structure&Oil-Resistant Coating for Automotive Powertrain PlantUS$ 120 - 600MOQ: 5 Combos

-

NC Tool Box BlueTC-T823 for Inventory Management With Transparent 3C Tempered Glass Doors| BT30/BT50 Tapers for Medical Device ManufacturingUS$ 120 - 600MOQ: 5 Combos

-

HSK63 CNC Tool Cabinets UK Automated CT-H284 With Zero-Damage Storage& Adjustable Laminates-500kg Load Capacity for Heavy Engineering Tool CribUS$ 120 - 600MOQ: 5 Combos

-

CLCO23 Janitorial Cabinet |Heavy Duty Cold Rolled Steel With Mop Hanger 1800mm Tall Lockable Broom Closet for Canada Hospital Storage|KD StructureUS$ 80 - 200MOQ: 5 Combos

-

SAKA23 Ventilated Metal Cleaning Supply Storage Cabinet |Cold Rolled Steel Flat Packed Utility Locker With Adjustable Shelves for Office in GermanyUS$ 80 - 200MOQ: 5 Combos

-

Classic Metal Storage Cabinet CMMSD34 KD Design-Anti-rust Powder Coated With Removable Drip Tray|2-Door Cleaning Tool Organizer for Hotel in FranceUS$ 80 - 200MOQ: 5 Combos

-

Broom Storage Locker CLPD345-Industrial Cold Rolled Steel |3-Point Locking System 900x400x1800mm KD Metal Utility Closet for Factory in USAUS$ 80 - 200MOQ: 5 Combos

-

DWIU43 Double Door Housekeeping Cabinet With S-Hooks and Towel Bar |1.2mm Thickness Steel Locker for School in Netherlands-Easy AssembleUS$ 80 - 200MOQ: 5 Combos

-

DWRR43 Metal Janitorial Closet|Water-proof Cleaning Tool Cabinet With S-Tool Hook for Laundry Room |Space Saving KD Structure for AustraliaUS$ 80 - 200MOQ: 5 Combos

-

Janitor Supply Cabinet AISA23|Commercial Grade Cold Rolled Steel With Ventilation Holes |Knock-down Metal Storage Locker for Gym in Spain- OEM/ODMUS$ 80 - 200MOQ: 5 Combos