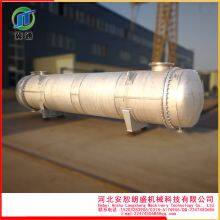

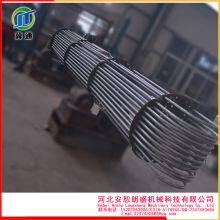

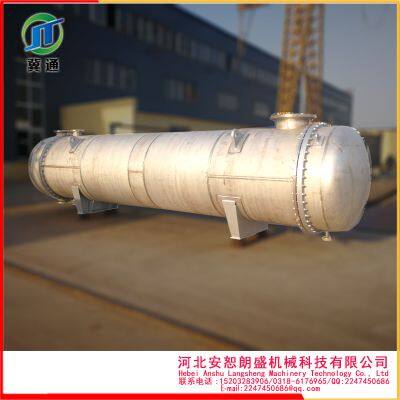

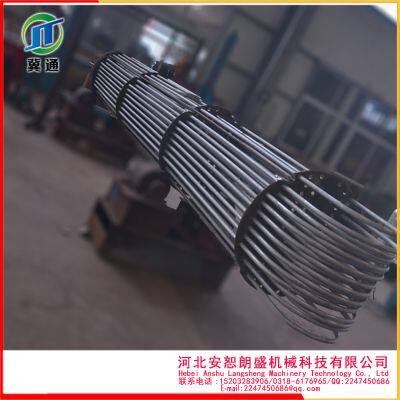

High-pressure Stainless Steel and Carbon Steel Shell-and-tube Heat Exchangers; Reboilers, Heaters, Coolers, and Thermal Petrochemical Equipment.

A heat exchanger is a device that transfers some of the heat from a hot fluid to a cold fluid; it is also called a heat exchanger. Heat exchangers play an important role in chemical, petroleum, power, food, and many other industrial production processes. In chemical production, heat exchangers can be used as heaters, coolers, condensers, evaporators, and reboilers, and their applications are widespread.

Heat exchangers are suitable for different media, operating conditions, temperatures, and pressures, and their structural types also vary. The specific classification of heat exchangers is as follows: Classification by Heat Transfer Principle

1. Indirect-contact heat exchangers: Two fluids at different temperatures flow in a space separated by a wall. Heat exchange occurs between the two fluids through heat conduction at the wall surface and convection at the wall surface. Indirect-contact heat exchangers include shell-and-tube, coaxial, and other types. Indirect-contact heat exchangers are the most widely used type of heat exchanger.

2. Regenerative heat exchangers use a solid material as a heat storage medium to transfer heat from a high-temperature fluid to a low-temperature fluid. The hot medium first passes through the solid material to reach a certain temperature, and then the cold medium is heated by the solid material, thus achieving heat transfer. Regenerative heat exchangers include rotary and valve-switching types.

3. Fluid-connected indirect heat exchangers connect two surface heat exchangers via a circulating heat carrier. The heat carrier circulates between the high-temperature fluid and the low-temperature fluid, receiving heat in the high-temperature fluid and releasing it to the low-temperature fluid in the low-temperature fluid heat exchanger.

4. Direct contact heat exchangers, also known as mixing heat exchangers, are devices where two fluids directly contact and mix for heat exchange. Examples include cooling towers and gas condensers.

5. Dual heat exchangers combine both steam-water surface indirect heat exchange and water-water direct mixed-flow heat exchange methods. Compared to surface-type indirect heat exchangers, it has higher heat exchange efficiency; compared to direct steam-water mixing heat exchangers, it has higher stability and lower unit noise.

Classification by Application:

1. Heaters heat fluids to the necessary temperature, but the heated fluid does not undergo a phase change.

2. Preheaters preheat fluids, providing standard process parameters for operation.

3. Superheaters heat fluids (process gas or steam) to a superheated state.

4. Evaporators heat fluids to temperatures above their boiling point, causing them to evaporate; generally, a phase change occurs.

Classification by Structure: It can be divided into: floating head heat exchangers, fixed tube sheet heat exchangers, U-tube sheet heat exchangers, plate heat exchangers, etc.

Send Inquiry to This Supplier

You May Also Like

-

Shaft Couplings GIICL Drum Gear Coupling Mechanical High TorqueUS$ 998 - 9999MOQ: 10 Pieces

-

Shaft Couplings GICL Drum Gear Coupling Mechanical High TorqueUS$ 888 - 9999MOQ: 10 Pieces

-

Oil Refinery Refinery Explains the Refinery or Refinery Oil PlantUS$ 888 - 999MOQ: 50 Bags

-

Manufacture of Large Cardan Shaft Coupling by Mechanical Transmission Shaft CompanyUS$ 500 - 5000MOQ: 1 Bag

-

JZMJ Heavy-duty Flexible Diaphragm Coupling, High Torque, With Double Key.NegotiableMOQ: 1 Acre

-

500-10000 Ton Fuel Storage Tanks; Petrochemical Storage Tanks; Gasoline Storage Tanks With Internal Floating Roofs; Hot Water Storage Tanks.NegotiableMOQ: 1 Acre

-

Autoclave; Non-fired Bricks; Blocks; Concrete and Aerated Concrete Blocks; Covered Autoclave; Carbon Steel AutoclaveNegotiableMOQ: 1 Acre

-

Industrial Heater/high-power Hot Air Blower/small Steel Cannon Electric Heater(Wechat:13510231336)NegotiableMOQ: 2000 Pieces

-

Industrial Diesel/kerosene Oil HeaterNegotiableMOQ: 1

-

Industrial Electric Blanket Insulation Heater Jacket Temperature Controller Drum HeaterUS$ 280.12MOQ: 200 Pieces