High Capacity Full-Automatic Dip PVC Mold Machine for Efficient Small Black PVC Caps Production

Introduction: Boost Output & Cut Costs With Automated PVC Molding

For manufacturers focused on high-volume production of small-sized black PVC caps (8mm diameter, 14mm length), sleeves, or root protectors, the Full-Automatic Dip PVC Mold Machine is a transformative solution. Designed to eliminate low output, labor dependency, and quality inconsistencies—common pain points in manual or semi-automatic production—this machine integrates intelligent automation with energy-efficient design. Whether you’re a packaging supplier, component manufacturer, or industrial parts producer, it delivers rapid, reliable production to meet tight delivery timelines while reducing operational costs.

Core Advantages: High Productivity & Labor Savings

The machine’s standout strength lies in its ability to maximize output without compromising efficiency:

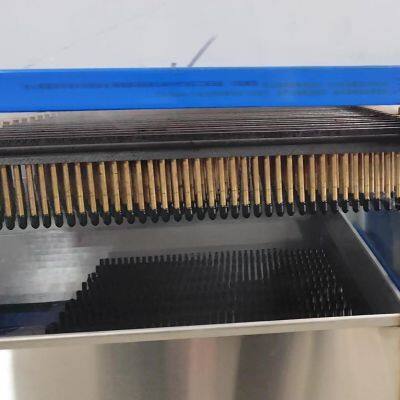

• Exceptional Capacity: The optimized mold base plate (495mm length) accommodates 200–300 molds per cycle, leveraging compact design to fit more molds in limited space. With a 3–4 minute cycle time per plate, it achieves impressive daily production volumes—ideal for scaling operations or fulfilling large orders.

• 100% Automated Process: From mold preheating and PVC plastisol liquid immersion to water cooling and demolding, the entire workflow is fully automated. This eliminates the need for continuous manual operation, cutting labor costs by 60% or more compared to semi-automatic alternatives.

• Energy-Efficient Performance: Equipped with a 30kW total power system, the machine balances high productivity with energy conservation. It avoids wasteful power consumption during idle periods, reducing long-term operational expenses.

Technical Specifications

Parameter | Details |

Machine Dimensions | 5330mm (L) × 1200mm (W) × 1100mm (H) |

Output per Cycle | 200–300 molds/plate (3–4 minutes/cycle) |

Material Tank Size | 800mm × 600mm × 160mm |

Production Material | PVC plastisol liquid |

Total Power | 30kW |

Production Lead Time | 20–25 days after payment |

Warranty | 2 Years |

After-Sales Service | Lifetime support |

Transport Package | Wooden packaging |

Origin | China |

Key Applications: Small PVC Components Manufacturing

This machine is specifically engineered for producing small PVC parts, with versatility to adapt to multiple use cases:

• Small Black PVC Caps: The primary application—8mm diameter, 14mm length caps used for protecting pipe ends, bolts, or electronic components from dust, moisture, and damage.

• PVC Sleeves: Thin-walled PVC sleeves for insulating wires, bundling cables, or enhancing the durability of small mechanical parts.

• Root Protectors: PVC root sleeves for horticultural or industrial use, shielding plant roots or small pipelines from external wear.

Its compatibility with PVC plastisol liquid ensures smooth, uniform coating on all small components, making it a valuable asset for packaging, electronics, construction, and horticultural supply industries.

Why Choose This Full-Automatic Dip PVC Mold Machine?

Beyond productivity and cost savings, this machine offers tangible long-term value:

• Reduced Defects: Automated processes minimize human errors (e.g., misfeeding, uneven immersion) that cause defective products, lowering scrap rates and material waste.

• Reliable Safety Features: Integrated leakage protection, power-off protection, and fault early warning mechanisms prevent electrical hazards and batch scrapping—critical for maintaining consistent production.

• Strong After-Sales Support: A 2-year warranty and lifetime after-sales service ensure peace of mind, with technical support available to resolve operational issues quickly.

For manufacturers looking to scale small PVC component production, cut labor costs, and meet high-demand timelines, this machine is a strategic investment that delivers measurable returns.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Dip PVC Plastisol Coating Equipment Line For Metal Handles RacksUS$ 2000 - 40000MOQ: 1 Set

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

High Efficiency Automatic PVC Dip Mold Machine for Small Caps (200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Small Plastisol PVC Cap Molding Machine (Automatic, 200–300 Molds/Plate)US$ 2000 - 40000MOQ: 1 Set

-

Automatic PVC Dip Coating Machine for 8mm×14mm Small CapsUS$ 2000 - 40000MOQ: 1 Set

-

Greenhouse Wiggle Wire Making Machine, Pvc-coated Wiggle Wire MachineUS$ 2000 - 40000MOQ: 1 Set

-

PVC Plastisol Production Equipment, Used to Produce Pvc Plastisol LiquidUS$ 2000 - 40000MOQ: 1 Set

-

Precision-Engineered PVC Plastisol Production Equipment Machine, Mixing TanksUS$ 2000 - 40000MOQ: 1 Set

-

Liquid PVC Plastisol Mixing Equipment MachinesUS$ 2000 - 40000MOQ: 1 Set

-

Thermal Flame Spraying Machine for Thermoplastic PowderUS$ 1000 - 5000MOQ: 1 Set