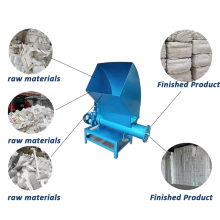

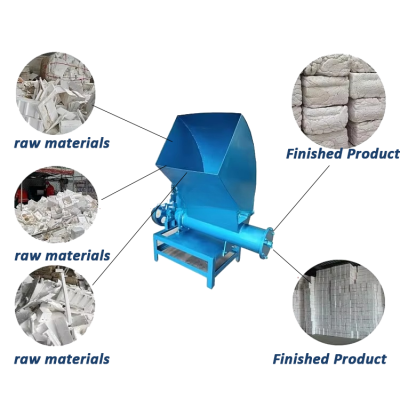

Industrial Foam Hot Melt Machine for XPS Board & Home Appliance Packaging Processing

As a trusted manufacturer established in 2019, Henan Panqi Heavy Industry Technology Co., Ltd. proudly introduces our Industrial Foam Hot Melt Machine, designed to revolutionize your XPS board and home appliance packaging processes. With a sprawling factory spanning 10,000-30,000 square meters and a dedicated team of 51-100 professionals, we leverage cutting-edge technology to deliver machines that enhance production efficiency and reduce operational costs. Our commitment is reflected in an annual export value of US$5-10 million, serving diverse markets from North America to Southeast Asia, ensuring global reliability and support. This machine embodies our expertise in industrial solutions, offering unparalleled durability and precision for high-volume packaging needs.

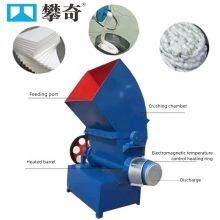

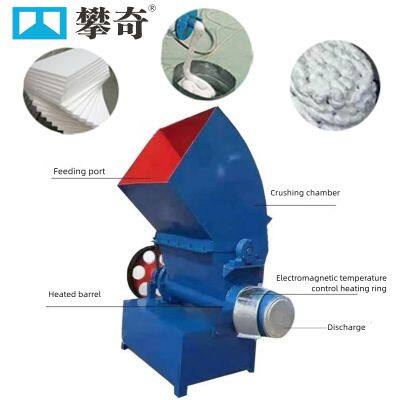

The Industrial Foam Hot Melt Machine excels in handling foam materials for XPS boards and appliance packaging, featuring robust components that ensure long-term performance. Key technical specifications include:

Advanced Heating Mechanism: Equipped with a precision temperature control system that maintains optimal melting points between 150°C and 250°C, preventing overheating and ensuring consistent foam adhesion.

Customizable Capacity: With adjustable processing rates, this machine can handle loads up to 100 kg per hour, adapting seamlessly to varying production scales for XPS boards or appliance components.

User-Friendly Operation: An intuitive control panel allows for easy setup and monitoring, reducing training time and minimizing errors during packaging tasks.

Durable Construction: Built from high-grade stainless steel, it resists corrosion and wear, making it ideal for harsh industrial environments while extending lifespan.

For detailed technical specifications, refer to the table below, which highlights core parameters based on standard models. Note that values can be tailored to specific requirements upon consultation.

This machine delivers significant advantages for your business, such as reducing material waste by up to 20% through precise melting and improving packaging integrity for appliances like refrigerators or TVs. For XPS board applications, it ensures uniform bonding, enhancing product durability while cutting energy consumption. Clients report faster turnaround times and lower maintenance costs due to its modular design, which allows easy part replacement. Overall, it streamlines workflows in packaging plants, boosting output without compromising on quality.

Backed by Henan Panqi Heavy Industry's extensive global reach—exporting to major markets including North America, South America, and Southeast Asia—this machine comes with reliable after-sales support from our Zhengzhou-based facility. Our annual exports of US$5-10 million demonstrate a proven track record in delivering industrial-grade solutions, ensuring your investment is secure and efficient. We encourage you to contact us for a customized quote; experience how this machine can elevate your packaging processes and drive operational excellence.

Frequently Asked Questions (FAQ)

What types of foam can this machine process? It is optimized for XPS (extruded polystyrene) boards and common packaging foams used in home appliances, ensuring strong adhesion without degradation.

How energy-efficient is the heating system? The advanced temperature control reduces power consumption by maintaining stable heat levels, leading to lower operational costs over time.

Are certifications available for this machine? Our products adhere to industry standards; specific certifications can be discussed based on regional requirements upon request.

Can it handle different sizes of packaging materials? Yes, with customizable settings, it accommodates various dimensions, making it versatile for small or large appliance components.

What is the typical installation process? Installation is straightforward, often requiring basic electrical setup; we provide remote guidance or optional on-site support for seamless integration.

How does the machine ensure safety during operation? Built-in features like automatic shut-off and thermal sensors prevent hazards, prioritizing user safety in industrial settings.

What maintenance is required? Routine checks involve cleaning the heating elements and lubricating moving parts; detailed manuals and support are included for easy upkeep.

What is the lead time for delivery? Delivery times vary but typically range from 4-8 weeks, depending on customization and port of shipment like Qingdao or Shanghai.

Send Inquiry to This Supplier

You May Also Like

-

Pearl Cotton Granulator With Water Cooling System for Stable PerformanceNegotiableMOQ: 1 Set

-

Energy-Efficient Pearl Cotton Granulator With CE Standard Compliant DesignNegotiableMOQ: 1 Set

-

Stainless Steel EPE Pelletizing Machine With PLC Control SystemNegotiableMOQ: 1 Set

-

EPE Pelletizer With 1-Year Warranty and On-Site Technical SupportNegotiableMOQ: 1 Set

-

High-Speed EPE Pelletizer With 1200rpm Rotor for Continuous OperationNegotiableMOQ: 1 Set

-

Compact Pearl Cotton Pelletizer With 380V Power for Small-Scale RecyclingNegotiableMOQ: 1 Set

-

Industrial EPE Pelletizer With 15kW Motor for High-Density Foam GranulationNegotiableMOQ: 1 Set

-

Automatic Pearl Cotton Granulator With 500kg/h Output for Packaging Material RecyclingNegotiableMOQ: 1 Set

-

High Efficiency EPE Pelletizing Pearl Cotton Granulator Expanded Polyethylene Foam Recycling Granulator MachineUS$ 596 - 6900MOQ: 1 Set

-

High Quality Hot Melt Extruder Plastic Recycling Machine EPS XPS EPP Foam Plastic Pelletizing Machine Foam MachineryUS$ 596 - 6900MOQ: 1 Set