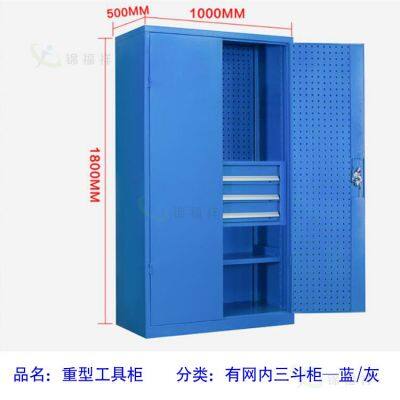

Cold Rolled Steel Warehouse Tool Locker Powder Coated Finish Anti-Corrosion

Transform your warehouse or industrial facility with our Cold Rolled Steel Warehouse Tool Locker, featuring an advanced powder coated finish and superior anti-corrosion protection specifically engineered for demanding industrial environments where durability and longevity are paramount. This professional-grade storage solution represents the pinnacle of warehouse locker design, combining premium materials with advanced protective coatings to deliver exceptional performance in harsh industrial conditions where equipment protection and security are critical for operational success.

Our warehouse tool locker is manufactured from high-quality cold rolled steel with precise thickness control ranging from 0.8mm to 2.0mm, ensuring exceptional structural integrity and uniform strength throughout the entire cabinet structure. The cold rolling process creates steel with superior surface finish and enhanced mechanical properties compared to hot-rolled alternatives, providing better dimensional accuracy and improved performance in industrial applications. Each component undergoes rigorous quality testing to meet ASTM A1008 standards for commercial quality cold rolled steel, guaranteeing consistent excellence and reliability in every unit produced.

The cold rolled steel construction provides enhanced tensile strength and improved surface hardness, making it ideal for warehouse applications where impact resistance and durability are essential. The material’s uniform thickness and consistent properties ensure predictable performance under various load conditions, while the smooth surface finish provides an excellent foundation for the powder coating application, ensuring optimal adhesion and long-lasting protection in demanding industrial environments.

Advanced Powder Coated Finish TechnologyThe cornerstone of our warehouse tool locker is the sophisticated powder coating system that provides superior protection against environmental factors and chemical exposure. The powder coating process involves electrostatic application of high-quality polymer powder followed by controlled curing at optimal temperatures, creating a uniform, durable finish that exceeds traditional liquid coating performance in both protection and appearance.

| Powder Coating Feature | Specification | Performance Benefit |

|---|---|---|

| Coating Thickness | 60-80 microns | Optimal protection thickness |

| Curing Process | 180°C for 20 minutes | Complete polymer cross-linking |

| Surface Hardness | 2H-3H pencil hardness | Scratch and abrasion resistance |

| Chemical Resistance | Excellent against solvents, oils | Industrial chemical protection |

| UV Stability | 500+ hours exposure testing | Outdoor and bright light resistance |

| Color Options | 15+ standard colors | Customization available |

The powder coating creates a seamless protective barrier that is chemically bonded to the steel surface, providing superior resistance to chipping, peeling, and fading compared to traditional paint finishes. The coating thickness is precisely controlled to ensure consistent protection across all surfaces, while the curing process creates a cross-linked polymer network that delivers exceptional hardness and chemical resistance. The finish is available in multiple color options to match facility color schemes or safety coding requirements.

Comprehensive Anti-Corrosion Protection SystemOur warehouse tool locker incorporates multi-layered anti-corrosion protection that ensures long-term performance even in harsh industrial environments with high humidity, chemical exposure, or temperature variations. The protection system begins with the cold rolled steel substrate that naturally provides better corrosion resistance than hot-rolled alternatives, followed by chemical pretreatment processes that prepare the steel surface for optimal coating adhesion and additional protection.

The anti-corrosion system includes zinc-rich primer applications in critical areas and weld points, providing sacrificial protection that prevents rust formation even if the surface coating is damaged. The powder coated topcoat provides additional barrier protection against moisture, chemicals, and environmental contaminants, while the sealed edge design prevents moisture ingress at vulnerable points where corrosion typically begins.

The warehouse tool locker features reinforced construction design specifically engineered for demanding industrial and warehouse applications. The cabinet utilizes heavy-gauge steel framing with reinforced stress points at door openings, shelf supports, and mounting locations, ensuring structural integrity even under maximum load conditions of up to 800 pounds distributed weight.

The door construction includes continuous hinge designs with welded steel pins that prevent sagging and ensure smooth operation even under frequent use. The reinforced locking mechanisms feature steel lock plates and hardened steel components that resist tampering and provide secure storage for valuable tools and equipment. Each shelf includes support brackets with weight distribution technology that prevents sagging and maintains level storage surfaces even under heavy loads.

Versatile Storage Configuration OptionsOur cold rolled steel warehouse locker offers flexible storage configurations to accommodate various tool types, equipment sizes, and organizational requirements. The standard configuration includes adjustable shelving systems with multiple height settings, allowing for customized storage solutions that maximize space utilization while maintaining easy accessibility to stored items.

| Storage Configuration | Capacity | Dimensions | Ideal Applications |

|---------------------|------------|-------------------|

| Standard Shelves | 150 lbs per shelf | 12"W x 18"D x 6"H spacing |

| Heavy-Duty Shelves | 250 lbs per shelf | 12"W x 18"D x 12"H spacing |

| Tool Hanging Area | 50 lbs total | Full-height door panel with hooks |

| Small Parts Storage | 20 lbs per compartment | Integrated bins and dividers |

| Bulk Storage Area | 400 lbs total | Lower compartment for large items |

The locker’s interior organization system includes optional dividers, tool holders, and accessory hooks that can be configured based on specific storage requirements. The ventilated door panels promote air circulation to prevent moisture buildup and protect sensitive tools from environmental damage. Each configuration option is designed to maintain structural integrity while providing maximum flexibility for different warehouse applications.

Industrial-Grade Security FeaturesSecurity is paramount in warehouse environments, which is why our tool locker incorporates premium security features throughout its design. The locker features heavy-duty locking mechanisms with pick-resistant cylinders and reinforced steel strike plates that provide superior protection against unauthorized access. The locking system includes master key capabilities for administrative access while maintaining individual user security.

The door construction includes continuous piano hinges with welded steel pins that prevent removal and ensure smooth operation under frequent use. The reinforced door frames include internal bracing that adds structural integrity and resists forced entry. Each locker can be configured with combination lock options or keyed systems depending on specific security requirements and user access patterns.

Quality Assurance and Technical SpecificationsOur cold rolled steel warehouse tool locker meets the highest industry standards for quality and performance in industrial applications:

| Technical Specification | Detail |

|---|---|

| Material | Cold rolled steel, 0.8-2.0mm thickness |

| Coating System | Powder coated, 60-80 microns thickness |

| Corrosion Protection | Multi-layer pretreatment and topcoat system |

| Weight Capacity | 800 lbs total distributed load |

| Shelf Capacity | 150-250 lbs per shelf (varies by type) |

| Lock System | Heavy-duty keyed or combination locks |

| Dimensions | 72"H x 36"W x 18"D (customizable) |

| Certification | ASTM A1008 commercial quality steel |

| Warranty | 5-year limited warranty |

Each warehouse tool locker undergoes comprehensive quality control inspections throughout the manufacturing process. Our quality assurance program includes dimensional verification, coating thickness testing, corrosion resistance evaluation, and operational testing of all moving components. This attention to detail ensures that each locker meets or exceeds industry standards for performance and durability in demanding warehouse environments.

Investment in Industrial Storage ExcellenceInvesting in our Cold Rolled Steel Warehouse Tool Locker represents a strategic decision to enhance equipment protection, organization, and overall operational efficiency in warehouse environments. The superior cold rolled steel construction and advanced powder coating system contribute to extended equipment life, reduced maintenance requirements, and improved organization in industrial operations.

The locker’s durable construction and anti-corrosion protection ensure long-term performance even in harsh industrial conditions, making it a cost-effective investment for facilities requiring reliable storage solutions. Whether you’re equipping a new warehouse or upgrading existing storage infrastructure, this cold rolled steel tool locker provides the foundation for secure, organized, and efficient equipment management that supports operational excellence and facility productivity.

Transform your warehouse storage capabilities with our premium cold rolled steel tool locker. Contact our industrial storage specialists today to configure the perfect storage solution for your specific warehouse requirements, and experience the difference that premium construction and advanced coating technology can make in your daily operations, equipment protection, and overall facility efficiency.

Send Inquiry to This Supplier

You May Also Like

-

Steel Chemical Storage Cabinet With Glass Doors for Laboratory UseUS$ 350 - 700MOQ: 5 Combos

-

Flame-Resistant Gallon Cabinet - Compliant Chemical Storage for Manufacturing PlantsUS$ 50 - 400MOQ: 10 Sets

-

Lab Safety Gallon Cabinet - Ventilated Storage for Volatile Reagents & Research ChemicalsUS$ 50 - 400MOQ: 10 Sets

-

Auto Shop Gallon Cabinet - Static-Safe Fuel Storage for Automotive Repair ShopsUS$ 50 - 400MOQ: 10 Sets

-

Hengna Educational Lab Gallon Cabinet - Safe Chemical Storage for Schools & University Science DepartmentsUS$ 50 - 400MOQ: 10 Sets

-

Hengna Medical Facility Gallon Cabinet - HIPAA Compliant Storage for Flammable Medical SuppliesUS$ 50 - 400MOQ: 10 Sets

-

Petrochemical Gallon Cabinet - Explosion-Proof Storage for Oil & Gas Industry Facilities SupplierUS$ 50 - 400MOQ: 10 Sets

-

Food Grade Gallon Cabinet - Storage for Food Processing Chemicals ManufacturerUS$ 50 - 400MOQ: 10 Sets

-

Hengna Construction Site Gallon Cabinet - Portable Fire-Resistant Storage for Construction Materials ManufacturerUS$ 50 - 400MOQ: 10 Sets

-

Hengna Electronics Factory Gallon Cabinet - ESD-Safe Storage for Electronics Manufacturing Chemicals SupplierUS$ 50 - 400MOQ: 10 Sets