AX800-B7 CNC Fully Automatic Carbide Circular Saw Blade Grinder for Precision Sharpening of Front & Back Angles

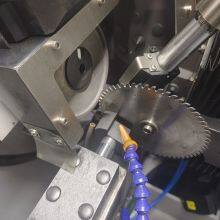

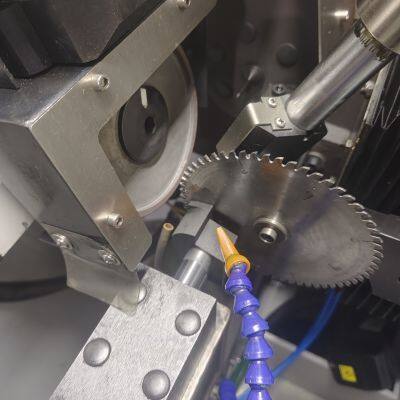

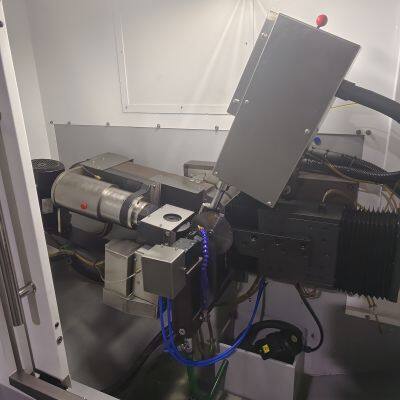

The Aoxiang AX800-B7 Automatic Alloy Circular Saw Blade Sharpening Machine is a high-precision device specially designed for the sharpening of cemented carbide circular saw blades. The machine adopts a fully enclosed structure, integrating a 24V-LED lighting and an exhaust system, with a power supply specification of three-phase 380V/50Hz. It can process various alloy saw blades with a diameter of 80-800mm, and easily complete the precision sharpening of the rake angle and clearance angle of various tooth profiles.

The equipment supports one-time forming sharpening of flat-ladder teeth, and the processing of bevel teeth only requires inputting angle values supplemented by multi-directional motion compensation. A single tooth can be repeatedly sharpened for 1–3 times, with the grinding accuracy controlled within 0.03mm. It is simple and easy to operate, without the need for unlock and lock buttons, and the system automatically locks according to operational requirements. While restoring the sharpness of the saw blade, it significantly extends its service life, with each saw blade being reusable for 20–30 times. The single-machine capacity reaches 30–50 pieces in 8 hours, making it an ideal basic equipment for saw blade usage and manufacturing enterprises.

The AX800-B7 is equipped with a motion controller and a 10-inch color touch screen, with a user-friendly Chinese-English bilingual interface. The feed system adopts a precision absolute encoder servo motor matched with a precision ground lead screw; the swing angle mechanism uses an absolute encoder servo motor combined with an RV reducer; the forward and backward movement is also completed by an absolute encoder servo motor cooperating with a precision reducer and a grinding-grade lead screw. The tooth shifting mechanism is driven by an absolute servo motor matched with a ground lead screw, and the saw blade replacement and movement are also controlled by an absolute servo motor—only the front and rear end points need to be set. The clamping mechanism is driven by an air cylinder, and the pneumatic system adopts AirTAC brand components, featuring low noise and stable pressure. Key electrical components are selected from Schneider brand, and the grinding head spindle is driven by a 1.1Kw motor with a frequency converter, ensuring reliable overall performance.

The entire machine undergoes strict quality inspection before leaving the factory, ensuring stable performance and long-term durability of the equipment in high-efficiency production environments.

Technical parameter table of AX800-B7 alloy saw blade grinding machine | |

Product Model | AX800-B7 |

Input voltage/frequency | AC380V/50Hz |

Equipment power | 3.6kw |

Applicable saw blade diameter | 80mm-800mm |

Applicable saw blade thickness | 2mm-10mm |

Applicable number of teeth | 1-999 |

Applicable tooth pitch | 7mm-100mm |

Machinable tooth profile | All commonly used tooth profiles on the market are acceptable |

Grinding accuracy | 0.02mm-0.03mm |

Main rake angle grinding angle | —10°to 40° |

Tooth surface tilt angle | (Left) L15° to R15° (Right) |

Back corner grinding angle | 6°-45° |

Tooth tip swing angle | (Left) L45° to R45° (Right) |

Grinding stroke | 1-28mm (absolute value servo stepless speed change) |

Grinding speed | 18-30 Teeth/min |

Grinding wheel specification | φ125mm*φ32mm*5mm |

Grinding wheel speed | 5000r/min |

Swing angle drive | absolute value servo |

human-machine interface | 10 inch, bilingual in Chinese and English |

Grinding head drive | absolute value servo |

Gear-driven | absolute value servo |

Clamping drive | cylinder |

Product size / Packaging size | 1780mm*1250mm*1880mm |

Equipment weight | 1180kg |

Send Inquiry to This Supplier

You May Also Like

-

Wire Manufacturing Testing Equipment Automatic Wire Bending Test Machine CNC Wire Reverse Bending MachineUS$ 2500 - 4000MOQ: 1 Set

-

Aluminium CNC Automatic Drilling MachineUS$ 10,500 - 12,500MOQ: 1 Set

-

Small Cnc Automatic Lathe CK0640AUS$ 4,000 - 15,000MOQ: 1 Set

-

20-3 Cnc Automatic LatheUS$ 5,000 - 50,000MOQ: 1 Set

-

0.05mm Preciion CNC Automatic BenderUS$ 4,200 - 11,000MOQ: 1 Set

-

GTQ5-12 CNC Automatic Straightening and Cutting MachineNegotiableMOQ: 1 Unit

-

Cheaper High Quality Cnc Automatic Slitting MachineryUS$ 250,000 - 350,000MOQ: 1 Set

-

Cnc Automatic Channel Letter Making MachineUS$ 6,050 - 8,550MOQ: 1 Set

-

SRH99-1 CNC Automatic Toroidal Core WinderNegotiableMOQ: 1 Set

-

Ribbon Cnc Automatic Tape Cutting MachineNegotiableMOQ: 1 Set