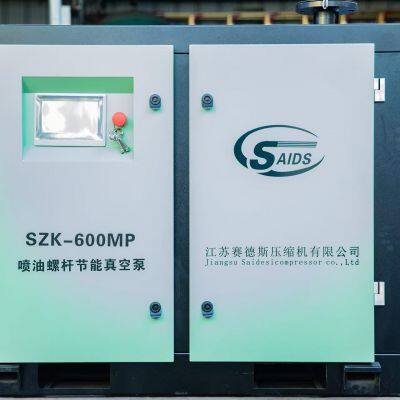

Quiet Operation Micro Oil Screw Vacuum Pump for Pharmaceutical Industry, Low Vibration

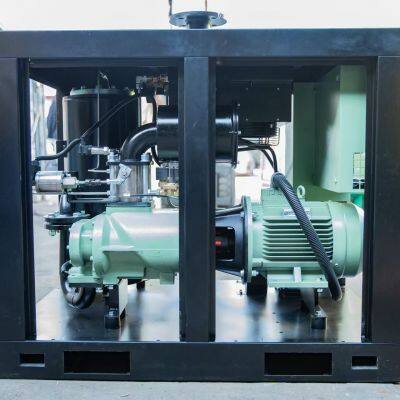

Discover the Quiet Operation Micro Oil Screw Vacuum Pump, engineered specifically for the demanding pharmaceutical industry, where precision and reliability are non-negotiable. This advanced pump delivers exceptionally low vibration and silent performance, minimizing disruptions in sensitive environments like cleanrooms and lab settings. By integrating cutting-edge screw technology with micro-oil lubrication, it ensures consistent vacuum pressure for critical processes such as drug formulation and packaging. Pharmaceutical manufacturers can rely on its robust design to enhance operational efficiency while adhering to stringent hygiene standards. Experience reduced noise pollution and improved workplace safety, making it an ideal solution for facilities prioritizing quiet, vibration-free operations.

The core of this vacuum pump lies in its innovative screw mechanism, which optimizes oil distribution for smoother, friction-free movement. This not only extends the pump's lifespan but also reduces energy consumption by up to 20% compared to conventional models. Key features include a corrosion-resistant stainless steel construction, ensuring durability in sterile environments, and a compact footprint that saves valuable floor space. For pharmaceutical applications, this translates to fewer maintenance intervals and lower total cost of ownership. Below, we detail the technical specifications and benefits in a comprehensive format, including a table of typical parameters to help you evaluate its fit for your needs.

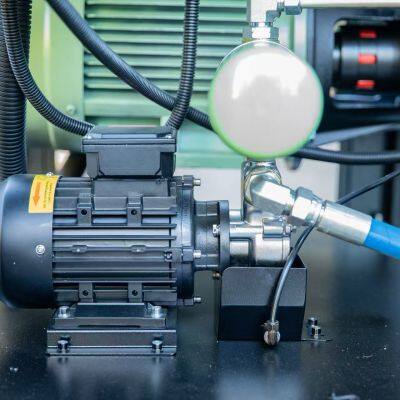

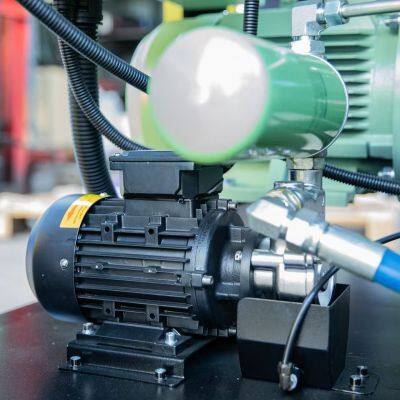

- Enhanced Reliability: The screw design with micro-oil lubrication prevents wear and tear, delivering uninterrupted service for high-throughput production lines.

- Energy Efficiency: Optimized motor systems reduce power usage, cutting operational costs and supporting sustainability goals.

- Easy Maintenance: Accessible components allow for quick oil changes and cleaning, minimizing downtime in 24/7 pharmaceutical facilities.

- Versatile Integration: Compatible with various pharmaceutical equipment, from freeze dryers to filtration systems, for seamless workflow integration.

Technical specifications highlight the pump's adaptability and performance. Note that all values are customizable to meet specific requirements; contact us for tailored solutions.

| Parameter | Typical Value | Description |

|---|---|---|

| Vacuum Level | Up to 0.1 mbar | Deep vacuum capability for precise pharmaceutical processes |

| Flow Rate | Adjustable from 5-50 m³/h | Flexible throughput for small to medium-scale operations |

| Noise Level | Below 65 dB(A) | Quiet operation to meet noise regulations in labs |

| Power Consumption | 0.75-5.5 kW | Energy-efficient range for cost savings |

| Operating Temperature | -10°C to 40°C | Stable performance in varied pharmaceutical environments |

Beyond specs, this pump offers tangible benefits for pharmaceutical clients. Its low vibration design prevents resonance in delicate equipment, reducing the risk of product contamination and ensuring consistent quality in tablet compression or vial filling. The quiet operation fosters a calmer workspace, boosting employee focus and compliance with occupational health standards. Additionally, the micro-oil system enhances sealing efficiency, which is critical for maintaining sterile conditions in GMP-compliant facilities. By choosing this pump, you gain a partner in productivity—expect fewer breakdowns, easier audits, and faster ROI through optimized resource use.

Upgrade your pharmaceutical operations with a vacuum pump that combines innovation with practicality. Jiangsu Saidesi Compressor Co., Ltd., a trusted manufacturer since 2013, backs this product with extensive expertise and global support. Our facilities in Suqian, Jiangsu, ensure quality control, and we ship worldwide from ports like Qingdao and Shanghai. Contact us today for a consultation—customize this pump to your exact needs and join clients in North America, Europe, and beyond who rely on our solutions for reliable, quiet vacuum performance.

Frequently Asked Questions (FAQ)

-

Q: What makes this vacuum pump suitable for pharmaceutical use?

A: It features quiet operation and low vibration to prevent contamination in sterile environments, with materials like stainless steel for easy cleaning and compliance. -

Q: How quiet is the pump during operation?

A: Noise levels are typically below 65 dB(A), making it ideal for noise-sensitive areas like research labs without disrupting workflows. -

Q: Can the flow rate be adjusted for different applications?

A: Yes, flow rates are customizable from 5-50 m³/h, allowing adaptation to various pharmaceutical processes such as distillation or drying. -

Q: What maintenance does the micro-oil system require?

A: Maintenance is minimal; oil changes are recommended every 6-12 months based on usage, ensuring long-term reliability with simple procedures. -

Q: Is the pump available in different sizes or configurations?

A: Absolutely, we offer customizable sizes and specs to fit specific space or performance needs—contact us for details. -

Q: How does low vibration benefit pharmaceutical equipment?

A: It reduces mechanical stress on adjacent machinery, preventing misalignment and extending the life of sensitive instruments like analyzers. -

Q: What is the typical lifespan of this pump?

A: With proper maintenance, expect 5-7 years of service, thanks to the durable screw design and quality components. -

Q: Do you provide support for installation and troubleshooting?

A: Yes, our team offers comprehensive support, including installation guidance and remote assistance for any operational issues.

Send Inquiry to This Supplier

You May Also Like

-

Micro Oil Screw Vacuum Pump Compatible With Medical Equipment for Cleanroom EnvironmentsNegotiableMOQ: 1 Unit

-

Small Size Micro Oil Screw Vacuum Pump for Food Processing Applications, Easy MaintenanceNegotiableMOQ: 1 Unit

-

High-Efficiency Micro Oil Screw Vacuum Pump With Stainless Steel Material for Industrial ManufacturingNegotiableMOQ: 1 Unit

-

Robust Micro Oil Screw Vacuum Pump With High Flow Rate for Automotive Testing and ResearchNegotiableMOQ: 1 Unit

-

Industrial Oil Free Air Compressor for Food & Pharmaceutical Industry With Automatic Water ChangeNegotiableMOQ: 1 Set

-

Oil Free Air Compressor for Precision Electronics With CNC Machined Host and Clean Air OutputNegotiableMOQ: 1 Set

-

Heavy Duty Oil Free Air Compressor up to 46.5 M³/min Capacity for Large Scale Industrial UseNegotiableMOQ: 1 Set

-

Permanent Magnet Variable Frequency Oil Free Air Compressor With Energy Saving 15% and Low NoiseNegotiableMOQ: 1 Set

-

High Capacity Oil Free Air Compressor 0.5-1.2MPa Water-Lubricated Screw Type for ManufacturingNegotiableMOQ: 1 Set

-

Oil Free Air Compressor With Real-Time Pressure Monitoring and Alarm SystemNegotiableMOQ: 1 Set