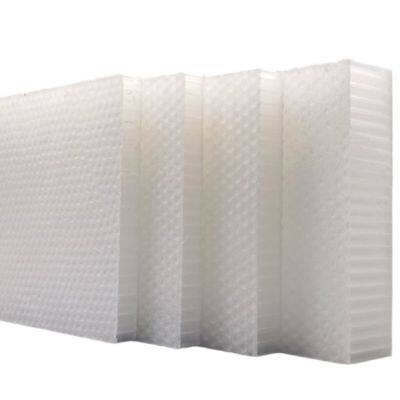

Characteristics of PP plastic honeycomb panels

1. Light weight: Light weight can reduce the load of transportation tools, increase their speed and lower transportation costs. It is widely used in the interior decoration of the shells, ceilings, partitions, decks, floors and other parts of transportation tools such as yachts, cars and trains. And the production of luggage.

2. It has strong compressive and impact resistance, capable of absorbing external forces and reducing damage caused by impacts and collisions. It is widely used in fields such as automotive bumpers and sports protective gear.

3. It has excellent sound insulation performance and can effectively attenuate and block the transmission of sound. It is widely used as the basic material for sound insulation equipment in noisy transportation tools such as yachts, cars, and bullet trains, as well as for decoration materials in noisy places.

4. It has excellent heat insulation performance and can effectively ensure the relative stability of the internal temperature, and is widely used in the box bodies of refrigerated trucks and box vans.

5. Strong water resistance and corrosion resistance: Due to the inherent characteristics of its raw materials, it can be used for a long time in environments with high water content and strong corrosiveness. It is widely applied in the construction of docks and the manufacturing of floating rafts at sea. Due to the transparency of the product, it can also be used in the production of fountains. When combined with activated carbon, it can also be applied to air filtration and purification equipment.

The hole diameters of our company's PP honeycomb board products range from Φ6 to Φ8 to Φ12MM

The processing thickness of PP honeycomb board products is: 6-100MM. The standard size is: 2440*1120mm. The maximum planar size of the board is: 3000*1500(MM). If the customer uses container transportation, the recommended size for the customer is: 2300*1150(MM), this size can maximize the utilization of container space, allowing customers to save transportation costs to the greatest extent.

For the convenience of customers' use, various specifications of PP non-woven fabric surfaces can be attached to both sides of the board

The T40 board is coated with 40G/M2 non-woven fabric on both sides, which can partially block the adhesive and is suitable for materials that require less adhesive and are relatively easy to bond.

Both sides of the T40F board are laminated with adhesive film and 40G/M2 non-woven fabric, which enables a better combination of the honeycomb itself and the non-woven fabric surface. In some fields, it can be directly used without the need to composite other material panels.

The T60 board is coated with 60G/M2 non-woven fabric on both sides, which better prevents the penetration of adhesives than the T30 and saves more adhesives.

The T60F board is coated with adhesive film on both sides and 60G/M2 non-woven fabric, which is applied in industries with special requirements for honeycomb cores and non-woven fabric.

Send Inquiry to This Supplier

You May Also Like

-

LOVELY HONEYCOMB BOARD CARDBOARD FOR FURNITUREUS$ 1 - 5MOQ: 1000 Square Meters

-

Sandwich Panel(paper Honeycomb Sandwich Panel & Sandwich Board)NegotiableMOQ: 1 Set

-

Honeycomb BoardNegotiableMOQ: 500 Square Meters

-

PVC Honeycomb Board Production Line Extrusion EquipmentUS$ 1155000 - 1155882MOQ: 1 Set

-

Aluminum Honeycomb Core Board Equipment, Honeycomb Aluminum Honeycomb Board Equipment,US$ 90000 - 125000MOQ: 1 Set

-

Aluminum Honeycomb Board Plate Building Curtain WallNegotiableMOQ: 1 Piece

-

PP Honeycomb Board Extrusion LineNegotiableMOQ: 1 Rod

-

Stone Grain Aluminum Honeycomb Panel/ Aluminum Honeycomb Board for Wall/ Aluminum Honeycomb Panel for CeilingUS$ 80 - 150MOQ: 300 Meters

-

PP Honeycomb Borad Extrusion LineNegotiableMOQ: 1 Set

-

Honeycomb Paperboard MachineNegotiableMOQ: 20 Units