Self-Regulating Long Distance Heating Cable, Industrial Grade, Pipeline Temperature Maintenance

Engineered for critical pipeline temperature maintenance across vast industrial facilities, our Self-Regulating Heating Cable delivers precise thermal control while significantly reducing energy consumption. Unlike constant-wattage alternatives, this intelligent cable automatically adjusts its heat output based on ambient conditions – eliminating overheating risks while cutting operational costs by up to 50%. With its robust industrial-grade construction, it withstands corrosive environments and extreme temperatures from -40°C to 65°C, making it ideal for:

- Long-distance oil & gas transfer pipelines

- Chemical processing plant fluid lines

- Water treatment facility pipe networks

- Freeze protection for fire suppression systems

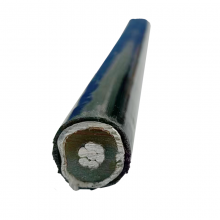

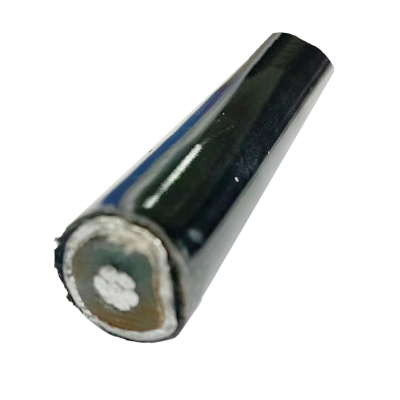

The core conductive matrix between parallel nickel-plated copper bus wires expands/resists current flow in response to temperature changes. This self-regulating technology provides:

| Feature | Technical Advantage | Operational Benefit |

|---|---|---|

| PTC Conductive Core | 10-50W/m automatic power adjustment | Energy savings & no control panels required |

| Cross-Linked Jackets | Fluoropolymer (FEP) / Polyolefin options | Resists chemicals, UV, moisture & abrasion |

| Cold-Lead Termination | Splice-free connection system | 15% faster installation vs. conventional models |

Custom configurations accommodate specific project requirements:

- Voltage compatibility: 120V, 240V, 480V AC systems

- Length customization: Manufactured to exact meter specifications

- Hazardous area versions: ATEX/IECEx certified for Zone 1/Division 1

Installation flexibility allows direct contact wrapping on pipes up to 300mm diameter without overheating concerns. The cable’s zero startup inrush current permits circuit lengths exceeding 200 meters – reducing power feed points for long runs.

Frequently Asked Questions:

Q: Can this cable be overlapped during installation?

A: Yes, the self-regulating design prevents overheating even when cables overlap – unlike constant-wattage heaters.

Q: What maintenance is required after installation?

A: Virtually maintenance-free operation. Annual insulation resistance checks are recommended for critical processes.

Q: How does it perform in submerged conditions?

A: With IP68-rated terminations and continuous polymer jackets, it operates reliably in wet/damp environments.

Q: Can existing installations be extended?

A: Field splicing is possible using manufacturer-supplied kits, but pre-terminated custom lengths ensure optimal reliability.

Q: What’s the typical lifespan in chemical plants?

A: 15+ years when using fluoropolymer-jacketed versions in corrosive environments.

Specify this heating solution for your next pipeline project to leverage reduced energy bills, simplified installation, and maintenance-free operation. Contact our engineering team for application-specific thermal calculations and hazardous area certifications documentation.

Send Inquiry to This Supplier

You May Also Like

-

ATEX Certified Heating Cable for Hazardous Oil & Gas Areas, Stainless Steel Armored ConstructionNegotiableMOQ: 50 Meters

-

High-Power Mineral Insulated Heat Tracing for Oil Wells, Customizable Watt Density & LengthsNegotiableMOQ: 50 Meters

-

Oil Well Heating Cable for Subsea Pipelines, Anti-Corrosion & Explosion-Proof Design, 220V/380VNegotiableMOQ: 50 Meters

-

Energy-Efficient Oil Pipeline Heating Cable With Self-Regulating Feature, Easy InstallationNegotiableMOQ: 50 Meters

-

High Temperature Mineral Insulated Heating Cable for Oil Wells, Custom Lengths Up to 2000mNegotiableMOQ: 50 Meters

-

Industrial Oil Well Heating Cable With Stainless Steel Sheath, 30W/m to 60W/m Power OptionsNegotiableMOQ: 50 Meters

-

Self-Regulating Heat Trace Cable for Oil Pipelines, -40°C to 205°C, IP68 Waterproof RatingNegotiableMOQ: 50 Meters

-

Explosion-Proof Mineral Insulated Heating Cable for Oilfield Equipment, IECEx/ATEX CertifiedNegotiableMOQ: 50 Meters

-

Self-Regulating Low-Temp Heating Cable for Plumbing and Roofs, 10W/m, 230V, Durable JacketNegotiableMOQ: 50 Meters

-

Energy-Saving Self-Regulating Heating Cable, 10W/m Output, Ideal for Pipe and Gutter ProtectionNegotiableMOQ: 50 Meters