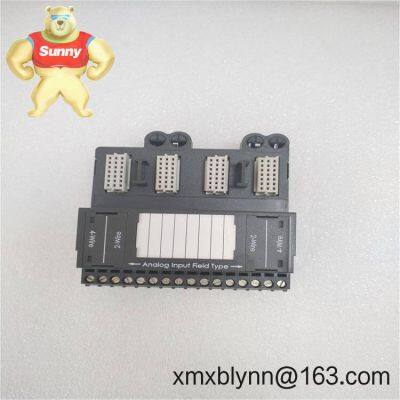

EMERSON VE4035S2B1 – System I/O Interface Module for Reliable DeltaV/Ovation Signal Integration

Warranty period: 365 days (replacement or repair coverage for functional faults under normal use)

Delivery time: typically 1 week if in stock; no more than one month at the latest

Payment terms: 50% advance payment; full payment prior to delivery

Express options: FedEx, UPS, DHL (we’ll book the fastest lane that fits your schedule)

System-compatible I/O interface – Designed for DeltaV/Ovation architectures, reducing integration risk.

Hot‑swappable maintenance – Typically allows replacement without full system shutdown, helping avoid production loss.

Backplane-powered 24 VDC – Clean cabinet wiring with power delivered through the carrier/baseplate.

Redundancy-ready designs – In many cases supports redundant system configurations to increase availability.

Signal flexibility – Works with common plant signals (4–20 mA, HART, DI/DO, RTD/TC) via compatible carriers/CHARMs.

Industrial temperature range – Suitable for control cabinets in typical plant environments.

Status diagnostics – Visual indicators and system diagnostics help troubleshoot faster.

| Brand / Model | EMERSON VE4035S2B1 |

| HS Code | 8537.10 (Boards/panels for electric control or distribution) |

| Power Requirements | 24 VDC supplied via system backplane/carrier (typical) |

| Operating Temperature | 0 to 55 °C cabinet ambient, non‑condensing (typical for VE-series) |

| Signal Input/Output Types | Analog 4–20 mA, HART, discrete 24 VDC, RTD/TC when used with the appropriate carriers/CHARMs |

| Communication Interfaces | System I/O bus for DeltaV/Ovation; redundancy support is application‑dependent |

| Installation Method | DIN‑rail/baseplate carrier installation; hot‑swap capable; keyed slot orientation |

Note: Exact capabilities depend on the specific system revision and the associated carrier/terminal components. If you share your DeltaV/Ovation version and cabinet layout, we’ll validate compatibility before shipment.

Application FieldsPower generation and utilities – boiler, turbine, balance-of-plant I/O consolidation

Oil & gas – upstream skids, midstream pump stations, downstream units with redundant control

Chemicals and petrochem – safety interlocks, analog control loops with HART diagnostics

Water & wastewater – distributed remote panels, pump control, process instrumentation

Pharmaceuticals & life sciences – controlled environments where downtime windows are tight

Pulp & paper – line upgrades where mixing legacy and new I/O is common

Procurement confidence – Matched to DeltaV/Ovation ecosystems to reduce project risk and rework.

Operational continuity – Hot‑swap and redundancy options help keep production online.

Lifecycle efficiency – Backward/forward compatibility in many cases limits cabinet changes during expansions.

Total cost control – Faster commissioning and simpler spares strategy can reduce labor and downtime costs.

Technical support – Pre‑shipment compatibility check and after‑sales assistance through the warranty period.

Cabinet environment – Install in a clean, ventilated control cabinet; maintain ambient 0–55 °C and non‑condensing humidity.

Wiring – Use OEM‑recommended carriers/terminal bases; follow proper grounding and shielding for analog/HART signals.

Redundancy – If using redundant modules, confirm slot/keying and firmware alignment before power‑up.

ESD and safety – Observe ESD handling; de‑energize affected circuits when practical; lockout/tagout per site policy.

Firmware & configuration – Align module firmware with your DeltaV/Ovation revision; back up configuration prior to swap.

Routine care – Periodically inspect connectors, clean dust with dry air, verify tight terminals, and review diagnostics.

Calibration – For analog loops, perform loop checks and, if applicable, HART device verification after installation.

Compliance: CE and RoHS typically applicable for VE‑series modules used in industrial control panels

Panel integration: Suitable for UL/NRTL‑listed control panels when installed per NEC/IEC guidelines

Manufacturer warranty: Emerson standard policy; additional 365‑day coverage provided by us for this unit

DeltaV/Ovation carriers/baseplates and terminal blocks (12‑pt/24‑pt, depending on I/O density)

CHARM I/O Carrier (CIOC) and compatible CHARMs for AI, AO, DI, DO, RTD/TC where applicable

Shielded field wiring and marshalling accessories for HART/analog loops

Redundant module sets when higher availability is required

Send Inquiry to This Supplier

You May Also Like

-

DSDP140B 57160001-ACX Power Module Real-time Quality Control and Machine OptimizationNegotiableMOQ: 1 Bag

-

VE3008 KJ2003X1-BB1 Module Interface for Receiving DevicesNegotiableMOQ: 1 Bag

-

KJ2005X1-MO1 Sensor For Real-time Monitoring and AnalysisNegotiableMOQ: 1 Bag

-

SE3008 KJ2005X1-MQ2 13P0072X082 Control Module Logical Computing PowerNegotiableMOQ: 1 Bag

-

PR9268/303-000 Electrodynamic Velocity Sensor VM-5Y1-02/GEM 1594-005-P001GUS$ 6550.00MOQ: 1 Pallet

-

EMERSON 1C31116G04 Ovation I/O Module – Reliable Field Signal Interface for Critical DCS ApplicationsNegotiableMOQ: 1 Combo

-

EMERSON 1C31122G01 – Ovation I/O Module for Reliable Process Signal IntegrationNegotiableMOQ: 1 Combo

-

EMERSON 1C31124G01 – Ovation I/O Module for 24 VDC Discrete Signal CollectionNegotiableMOQ: 1 Combo

-

EMERSON 1C31125G02 – Ovation Series Module for Reliable Plant I/O/control ExpansionNegotiableMOQ: 1 Combo

-

EMERSON 1C31150G01 – Ovation I/O Module for Dependable Plant AutomationNegotiableMOQ: 1 Combo