Triple Modular Redundancy (TMR) – Runs three independent processors voting on every action. One fails? The other two keep guarding your turbine. Not something you want failing during a black start.

SIL 3 Certified – Meets IEC 61508 standards out of the box. One refinery client told me this shaved six weeks off their safety system certification process.

Hot-Swappable – Replace modules without shutting down the turbine. Had a paper mill guy text me at 2AM saying he swapped one during a fiber buildup incident – saved them 12 hours of downtime.

Legacy Signal Support – Handles 4-20mA, 0-10V, and TTL inputs alongside modern Modbus. Keeps older plants from rewiring entire control rooms.

| Specification | Detail |

|---|---|

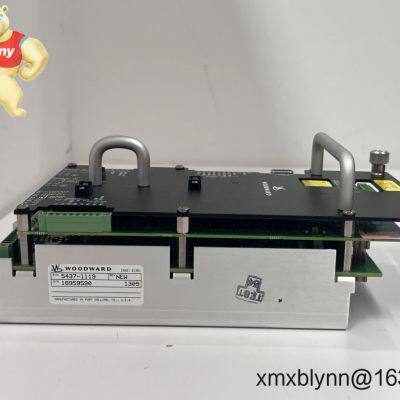

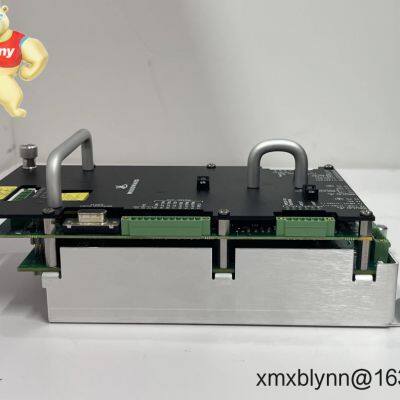

| Brand/Model | Woodward ProTech GII 5437-1119 |

| HS Code | 8537.10.0090 (Digital controllers) |

| Power Requirements | Nominal 24V DC (18-32V range) |

| Dimensions & Weight | 120 x 180 x 100mm / 1.8kg |

| Operating Temp | -20°C to +70°C (derate above 55°C) |

| Signal I/O | 8 configurable inputs (prox, LVDT, RTD), 4 relay outputs |

| Comms | Modbus RTU over RS-485, optional Ethernet |

You'll find these guarding critical rotating equipment where failure means catastrophic damage. Like in offshore gas compression trains – one North Sea platform engineer mentioned how it caught a governor valve sticking during a storm. Or chemical plants during catalyst regeneration when turbine loads swing wildly. Not for your garden-variety pumps, but where a $2M turbine could become shrapnel in 8 seconds.

Let's be real – it's not the cheapest option. But from my experience, the TMR architecture means fewer false trips than dual-redundant systems. One client calculated $187k in avoided downtime per year after switching from their old system. And Woodward's global service network? Had a tech onsite in Monterrey within 18 hours when a module failed – not something you get with boutique suppliers. Typically pays for itself in one avoided emergency shutdown.

Installation Reality CheckMount it in a NEMA 1 cabinet with at least 100mm clearance top/bottom – those power supplies get toasty. Keep it away from VFDs; I've seen EMI cause phantom trips when wiring wasn't segregated. Calibration? Every 24 months unless you're in a high-vibration environment (like that cement plant in Arizona that does it quarterly). And for heaven's sake, update firmware during planned outages – not when the turbine's screaming at 110% speed.

No-Spin Certifications & GuaranteesCE marked, UL 60730 certified, SIL 3 per IEC 61508. RoHS compliant because nobody needs lead in their control room. 365-day warranty – which feels short until you realize these modules typically run 15+ years. If we have it in stock (check our live inventory), we ship FedEx/UPS/DHL in 5 business days. Payment's 50% upfront, balance before shipping. No credit card fees, no hidden charges – just the module and documentation you need to keep turbines spinning safely.

Send Inquiry to This Supplier

You May Also Like

-

Woodward 8237-1006 Electronic Governor: Precision Speed Control for Critical Power SystemsNegotiableMOQ: 1 Bag

-

Woodward 8237-1369 ProTech-GII: Your Turbine's Last Line of Defense When Speed Goes CriticalNegotiableMOQ: 1 Bag

-

Woodward 8290-194 Electric Governor: Precision Speed Control for Critical Power SystemsNegotiableMOQ: 1 Bag

-

Woodward 8440-1923: Your Genset's Brains for Reliable Backup PowerNegotiableMOQ: 1 Bag

-

Woodward 8440-1546H: Precision Speed Control for Critical Turbine OperationsNegotiableMOQ: 1 Bag

-

Woodward 8440-1713 D Speed Controller: Your Turbine’s Steady Hand in Chaotic ConditionsNegotiableMOQ: 1 Bag

-

Woodward 9907-028: Precision Speed & Phase Synchronization for Critical Power SystemsNegotiableMOQ: 1 Bag

-

Woodward 9907-838 Load Sharing Module: Keep Your Parallel Generators Synced Without the HeadachesNegotiableMOQ: 1 Bag

-

Woodward EGCP-2 8406-121: Your No-Nonsense Generator Controller for Reliable PowerNegotiableMOQ: 1 Bag

-

9907-164 Governor Monitor and Adjust the Speed of Rotating MachineryNegotiableMOQ: 1 Bag