Gas Shield Dam/Air Shield Dam/Spillway Gate/Ecological Air-Bladder Support Gate on Sale

Material: High-strength synthetic fiber fabric (e.g., polyester canvas) coated with rubber (neoprene or EPDM) for impermeability and abrasion resistance.

Structure: Multi-layered composite structure with reinforcing cords to withstand water pressure and external impacts.

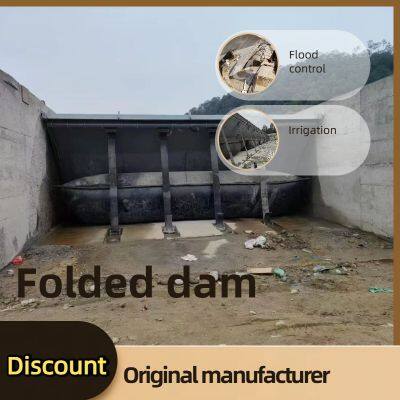

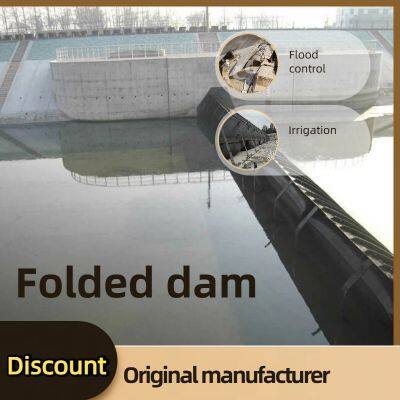

Function: When inflated, it forms the main water-retaining body; when deflated, it collapses to allow flood discharge or maintenance.

Shield Plate: Steel or reinforced concrete panels attached to the outer surface of the airbag, enhancing structural rigidity and preventing direct scouring by water flow.

Supporting Skeleton: Lightweight steel trusses or aluminum alloys connecting the shield plate and airbag, distributing loads evenly.

Bottom Anchorage: Embedded steel plates and anchor bolts fixed in the foundation concrete, securing the lower edge of the airbag and framework to prevent displacement under water pressure.

Side Anchorage: Guide rails and sealing strips installed on the dam abutments (concrete piers), limiting lateral movement and ensuring water tightness.

Inflation/Deflation Equipment: Air compressors, pressure relief valves, and pipelines for adjusting air pressure in the airbag (typical working pressure: 0.1–0.3 MPa).

Monitoring Devices: Pressure sensors, water level gauges, and flow meters connected to a central control unit for real-time data collection.

Automation Module: PLC (Programmable Logic Controller) system enabling remote or automatic operation (e.g., deflating during floods, inflating for water storage).

Water Stop Seals: Rubber gaskets between the airbag and anchorages, and between shield plates, preventing water leakage.

Protective Layers: Anti-ultraviolet coatings on the airbag surface and anti-corrosion paint on metal components to extend service life.

Inspection Channels: Walkways along the dam top or side for routine maintenance and emergency repairs.

2. Flexible and Rapid Water Level Adjustment

The operation of air-shield dams is controlled by inflation and deflation of the airbag, allowing for highly flexible water level regulation:

When water retention is needed (e.g., for irrigation or landscape), the airbag inflates quickly (usually within 10–30 minutes) to lift the dam face plate, forming a stable water storage area.

In case of flood risks or when water discharge is required, the airbag deflates rapidly, and the dam face plate lowers to open the river channel for unobstructed flood discharge. This rapid response is far more efficient than traditional dams, which require hours to adjust sluice gates.

3. Low Maintenance Costs and Long Service Life

Air-shield dams have a simple structural composition with fewer moving mechanical parts (e.g., no complex hoisting systems or gear transmissions). Their key components are designed for durability:

The inflatable airbag is made of high-strength composite rubber (with anti-abrasion, anti-aging, and anti-corrosion properties) that can withstand long-term immersion in water and resist damage from floating debris.

The dam face plate and anchoring system are treated with anti-corrosion processes (e.g., hot-dip galvanization for steel plates), reducing rust and wear.Routine maintenance mainly involves checking airtightness, cleaning the surface, and replacing sealing strips—tasks that are simple, low-cost, and do not require long-term shutdowns. With proper maintenance, the service life of an air-shield dam can exceed 20 years.

4. High Safety and Strong Anti-Impact Performance

Safety is a core advantage of air-shield dams, supported by multiple protective designs:

Emergency deflation function: In case of unexpected failures (e.g., airbag leakage, excessive upstream water level), the control system can trigger automatic or manual rapid deflation to lower the dam, avoiding risks such as dam overtopping.

Flexible anti-impact capability: The inflatable airbag has elastic properties, which can buffer the impact of floating objects (e.g., branches, stones) in the water. Unlike rigid dams, which may crack or deform under impact, the airbag absorbs energy through slight deformation, protecting the overall structure from damage.

Pressure safety protection: A safety valve is installed in the inflation system to automatically release excess air if the airbag pressure exceeds the design limit, preventing airbag burst.

5. Ecological and Landscape Compatibility

Air-shield dams have minimal impact on the river ecosystem and good landscape integration:

Unobstructed river channel when lowered: When the airbag is deflated, the dam face plate lies flat on the riverbed, restoring the natural flow of the river. This does not block the migration path of aquatic organisms (e.g., fish) or affect the transportation of sediment, protecting the river’s ecological balance.

Aesthetic appearance: The dam face plate has a smooth, flat surface, and the height can be adjusted to match the surrounding landscape (e.g., urban waterfronts or scenic lakes). Unlike traditional dams with bulky structures, air-shield dams blend naturally with the environment, enhancing the overall landscape quality.

6. Adaptability to Diverse Climatic and Hydraulic Conditions

Air-shield dams can be customized to adapt to different working environments:

Cold region adaptation: For areas with low temperatures (below 0°C), the airbag and pipelines can be wrapped with thermal insulation layers, and anti-freezing agents can be added to the compressed air system to prevent freezing and cracking.

Low-water-head suitability: They are optimized for low-water-head scenarios (usually 1–6 meters), which is more cost-effective than traditional sluice gates that are designed for high water heads but inefficient in low-head applications.

Bidirectional water retention (optional): Special designs can enable the dam to retain water on both the upstream and downstream sides, making it suitable for complex water conservancy projects (e.g., tidal rivers or inland lake regulation).

In summary, air-shield dams combine flexibility, economy, safety, and ecological friendliness, making them an ideal choice for modern small and medium-sized water conservancy projects that require efficient water regulation and low long-term costs.

Send Inquiry to This Supplier

You May Also Like

-

Multi-functional and Customizable Size Air Shield Dam for Water Control and LandscapeUS$ 1000 - 1100MOQ: 10 Square Meters

-

Easy Installation Home Wall Garage Drop Dam Door Reusable Detachable Aluminum Alloy Flood Barrier For Residential Flood ControlUS$ 1000 - 1100MOQ: 10 Square Meters

-

Advanced Automatic Control Air Shield Dam System for Precise River Level Regulation and HydropowerUS$ 1000 - 1100MOQ: 10 Square Meters

-

Smart Auto-Lift Air Shield Dam With Intelligent Control SystemUS$ 1000 - 1100MOQ: 10 Square Meters

-

Shipping Fee and Delivery Date to be Negotiated. Chat With Supplier Now for More Details.US$ 1000 - 1100MOQ: 10 Square Meters

-

Big Rubber Inflatable Waterproof Dam / Flood Protection Barrier/Water Injection Flood BarrierUS$ 1000 - 1100MOQ: 10 Square Meters

-

Pneumatic Shield Gate Shield-type Rubber Dam Air Shield Dam Spillway Gate Inflatable Rubber Dam Sold to Thailand, Malaysia, PhilippinesUS$ 1200 - 1500MOQ: 10 Square Meters

-

Air Shield Dam | Inflatable Rubber Dam With Steel Facing for Landscape and Flood ManagementUS$ 1200 - 1500MOQ: 10 Square Meters

-

ISO9001 Heavy Duty Shield Rubber Dam 20 Years Lifespan for Water ProjectUS$ 1200 - 1500MOQ: 10 Square Meters

-

Hydraulic Engineering Rubber Dam Air Shield Dam for RiverUS$ 1200 - 1500MOQ: 10 Square Meters