Haynes263 Alloy Pipe Meeting ASTM Standards for Boiler Tubes in Industrial Settings

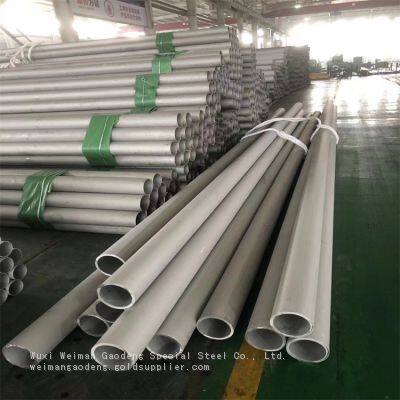

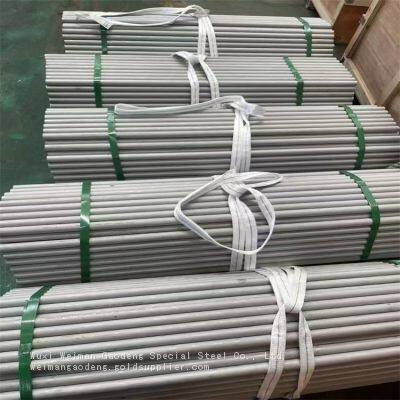

Discover the exceptional performance of our Haynes263 alloy pipes, engineered specifically for demanding industrial boiler applications. Manufactured by Wuxi Weiman Gaodeng Special Steel Co., Ltd. since 2017, these ASTM-compliant tubes deliver unmatched high-temperature stability and corrosion resistance in extreme operating environments. With over 100 employees and a 3,000m² manufacturing facility, we ensure consistent quality for global industrial applications.

Our Haynes263 pipes maintain structural integrity in temperatures reaching 1000°C (1832°F), significantly extending boiler system lifespan. The nickel-based alloy composition provides superior creep resistance while resisting oxidation in sulfur-containing atmospheres. Available in fully customizable dimensions, these tubes undergo rigorous quality checks at every production stage.

Key Technical Advantages:

- Enhanced Durability: 2-3× longer service life than standard stainless steels

- Thermal Stability: Maintains mechanical properties at continuous 800-900°C operation

- Weldability: Excellent joining characteristics without post-weld heat treatment

- Custom Fabrication: Cold drawing/pilgering for precise dimensional tolerances (±5%)

Typical Mechanical Properties:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | ≥900 MPa | ASTM E8 |

| Yield Strength (0.2% offset) | ≥550 MPa | ASTM E8 |

| Elongation | ≥30% | ASTM E8 |

| Hardness | ≤100 HRB | ASTM E18 |

The optimized chromium content (≈20%) provides exceptional oxidation resistance while molybdenum additions enhance strength at elevated temperatures. All pipes undergo ultrasonic testing and hydrostatic examinations per ASTM E213 standards, with full traceability documentation including chemical analysis reports.

Industrial Applications Include:

- Power generation boiler superheaters and reheaters

- Petrochemical cracking furnace tubes

- Waste-to-energy plant heat recovery systems

- Gas turbine combustion components

- Nuclear reactor heat exchangers

Frequently Asked Questions:

-

Q: What makes Haynes263 suitable for boiler applications?

A: Its unique γ' precipitation strengthening provides exceptional creep rupture strength at temperatures exceeding 700°C, outperforming conventional austenitic steels. -

Q: Can you supply pipes to specific ASTM sub-standards?

A: Yes, we regularly produce to ASTM B163 (seamless), B167 (nickel-chromium), and B517 (welded) standards. Specifications available upon request. -

Q: What documentation accompanies shipments?

A> All shipments include Mill Test Certificates per EN 10204 3.1, material chemical analysis, and mechanical test reports. -

Q: What is your production lead time?

A: Standard sizes ship within 30-45 days. Custom dimensions may require 60-75 days for manufacturing and testing. -

Q: Do you offer surface protection for international shipping?

A: Yes, we provide VCI coating or plastic end caps to prevent corrosion during transit.

Optimize your boiler system performance today

Leverage our manufacturing expertise to source reliable Haynes263 tubing solutions. With annual exports exceeding US$5 million to global markets including North America and Europe, we maintain consistent stock of common sizes while accommodating custom requirements. Contact our engineering team for material selection guidance and project-specific quotations.

All products ship from Shanghai, Ningbo, or Lianyungang ports with flexible incoterms options. Request samples to verify our material quality before volume procurement.

Send Inquiry to This Supplier

You May Also Like

-

UNS N06022 Welded Nickel Alloy Tube ASTM B622 Capillary Precision Welded PipeNegotiableMOQ: 1 Kilogram

-

ASTM B619 B622 Standard Customizable Inch Tube Astelloy C276 Hastelloy C22 Hastelloy C-2000 Hastelloy C-4 for SaleNegotiableMOQ: 10 Kilograms

-

UNS N10276 Nickel Alloy Seamless Tube ASTM B675 High-Temp Nickel Alloy PipeNegotiableMOQ: 1 Kilogram

-

UNS N06200 Precision Seamless Tube ASTM B167 Capillary Nickel Alloy Seamless PipeNegotiableMOQ: 1 Kilogram

-

UNS N06985 Welded Nickel Alloy Pipe ASME SB517 Nickel Alloy Welded TubeNegotiableMOQ: 1 Kilogram

-

UNS N06030 Seamless Nickel Alloy Pipe ASTM B516 Precision Seamless TubeNegotiableMOQ: 1 Kilogram

-

UNS N10001 Capillary Welded Tube ASME SB444 Nickel Alloy Welded PipeNegotiableMOQ: 1 Kilogram

-

UNS N10665 High-Temp Seamless Pipe ASTM B675 Nickel Alloy Seamless TubeNegotiableMOQ: 1 Kilogram

-

UNS N10675 Precision Nickel Alloy Tube ASTM B574 Capillary Precision PipeNegotiableMOQ: 1 Kilogram

-

UNS N09925 Welded Nickel Alloy Tube ASME SB366 Seamless & Welded PipeNegotiableMOQ: 1 Kilogram