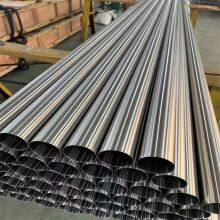

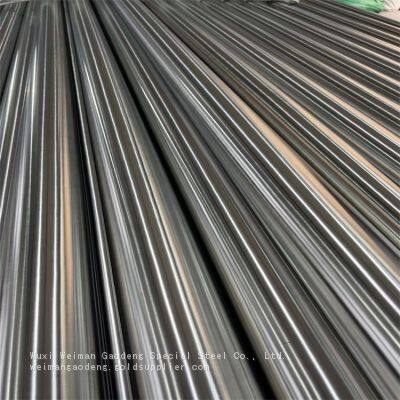

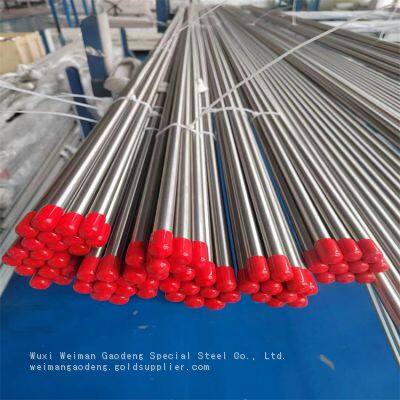

UNS N10665 High-Temp Seamless Pipe ASTM B675 Nickel Alloy Seamless Tube

I. Product Overview

Our nickel alloy tube series covers three main categories: Nickel Alloy Tubes, Capillary Precision Tubes, Welded Tubes, and Seamless Tubes. Crafted from premium UNS series nickel alloys (e.g., UNS N06455, N06022, N10276) and manufactured in compliance with ASTM/ASME standards (such as ASTM B619, ASME SB517), these tubes are engineered to perform in harsh environments—including high temperatures, high pressure, and corrosive conditions. They serve as critical components in industries like chemical processing, energy, and aerospace, delivering reliable pipeline solutions for industrial equipment.

II. Key Advantages1. Superior Material Performance

Our tubes are made from UNS series nickel alloys, each formulated to excel in specific conditions:

• High nickel content, combined with chromium, molybdenum, and iron, ensures exceptional corrosion resistance (resistant to strong acids, alkalis, and chloride-induced corrosion).

• Excellent high-temperature stability, withstanding continuous operation at 600–1200°C, making them ideal for high-heat applications.

• Good machinability, allowing for precise fabrication to meet custom design requirements.

2. Precision Manufacturing

• Capillary Precision Tubes: Produced via cold drawing/rolling, with outer diameters ranging from 0.5–20mm, wall thickness tolerances of ±0.01mm, and inner surface finish of Ra≤0.8μm—ensuring leak-free fluid flow and consistent performance.

• Seamless Tubes: Formed through hot rolling and cold working, with no weld seams, providing superior structural integrity and pressure resistance (operating pressure up to 10–30MPa).

• Welded Tubes: Fabricated using automated TIG welding, with welds that match the base material’s strength. Suitable for large-diameter (≥50mm) and long-distance pipeline needs, offering cost-effective solutions.

3. Compliance with International Standards

All products adhere to relevant ASTM/ASME standards, tailored to their specific alloys:

• UNS N06455: Complies with ASTM B619

• UNS N06022: Complies with ASTM B622

• UNS N10276: Complies with ASTM B675

• UNS N08825: Complies with ASTM B424

• (Full standard correspondence listed in Section IV)

We provide Material Test Reports (MTR) and non-destructive testing certificates (UT/MT) to verify compliance with customer specifications.

III. Product Types & Specifications

Tube Type | Outer Diameter Range | Wall Thickness Range | Length Range | Key Features |

Seamless Tubes | 6–630mm | 0.5–50mm | 1–12m (custom cut) | No weld seams, high pressure resistance |

Welded Tubes | 20–1200mm | 1–20mm | 6–18m | Smooth welds, cost-effective for large diameters |

Capillary Precision Tubes | 0.5–20mm | 0.1–2mm | 0.5–6m (with cutting/bending options) | Ultra-precise dimensions, polished inner surface |

IV. Alloy & Standard Reference

Alloy Grade | Corresponding Standard | Typical Properties | Target Applications |

UNS N06455 | ASTM B619 | Oxidation resistance, high-temperature creep strength | Gas turbines, heat treatment equipment |

UNS N06022 | ASTM B622 | Resistance to wet hydrogen sulfide, sulfuric acid | Chemical desulfurization, acid transport |

UNS N10276 | ASTM B675 | Resistance to concentrated nitric acid, hydrofluoric acid | Pharmaceutical, fertilizer production |

UNS N08825 | ASTM B424 | Resistance to seawater, chloride stress corrosion | Marine engineering, desalination |

UNS N07718 | ASTM B637 | High-temperature strength, fatigue resistance | Aerospace engines, high-pressure boilers |

UNS N06625 | ASTM B677 | Oxidation resistance, pitting resistance | Nuclear power, flue gas desulfurization |

V. Application Fields

• Chemical Industry: Acid/alkali transport pipelines, reactor coils, catalyst bed tubes

• Energy Sector: Oil/gas well casings, nuclear power heat exchanger tubes, coal-fired power plant desulfurization pipes

• Aerospace: Engine combustion chamber tubes, high-temperature exhaust pipes

• Pharmaceuticals: Precision fluid delivery tubes, sterile reaction equipment pipelines

• Marine Engineering: Seawater cooling systems, offshore platform pipelines

VI. Quality Control

• Raw Material Inspection: Each batch undergoes spectral analysis (PMI) to verify chemical composition.

• In-Process Monitoring: Online laser diameter measurement and ultrasonic thickness testing.

• Final Testing: Hydrostatic pressure testing, eddy current testing, and 100% radiography (RT) for welded tubes.

For custom specifications or technical inquiries, please contact our team—we ensure on-time delivery and dedicated after-sales support.

Send Inquiry to This Supplier

You May Also Like

-

UNS N08825 Welded Nickel Alloy Pipe ASTM B424 Nickel Alloy Welded TubeNegotiableMOQ: 1 Kilogram

-

UNS N08926 Capillary Seamless Tube ASME SB517 Precision Nickel Alloy PipeNegotiableMOQ: 1 Kilogram

-

UNS N06600 High-Temp Welded Pipe ASTM B444 Nickel Alloy Welded TubeNegotiableMOQ: 1 Kilogram

-

UNS N06601 Seamless Nickel Alloy Tube ASTM B167 Precision Seamless PipeNegotiableMOQ: 1 Kilogram

-

UNS N06025 Welded Capillary Tube ASME SB444 Nickel Alloy Welded PipeNegotiableMOQ: 1 Kilogram

-

UNS N06625 Seamless Nickel Alloy Pipe ASTM B677 Nickel Alloy Seamless TubeNegotiableMOQ: 1 Kilogram

-

UNS N06617 Precision Welded Pipe ASME SB516 Nickel Alloy Welded TubeNegotiableMOQ: 1 Kilogram

-

UNS N07718 High-Temp Seamless Tube ASTM B637 Nickel Alloy Seamless PipeNegotiableMOQ: 1 Kilogram

-

UNS N04400 Capillary Precision Pipe ASTM B163 Nickel Alloy Precision TubeNegotiableMOQ: 1 Kilogram

-

UNS N05500 Seamless & Welded Tube ASME SB366 Nickel Alloy PipeNegotiableMOQ: 1 Kilogram