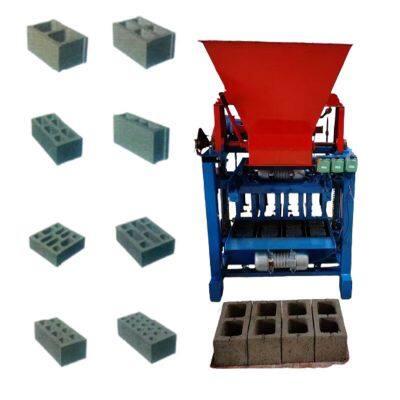

Industrial Grade Brick Making Machine Designed for Manufacturing and Production Facilities

Transform your construction material production with our industrial-grade brick making machine engineered specifically for manufacturing facilities seeking reliable, high-volume output. This robust system combines German-engineered precision with durable Chinese manufacturing to deliver consistent brick quality while optimizing operational efficiency. Designed for continuous operation in demanding environments, it significantly reduces labor costs while increasing production throughput for businesses scaling their construction material operations.

Core technological advantages include:

- Intelligent automation system with programmable logic control (PLC) for precise operation parameters

- Dual-pressure hydraulic mechanism ensuring uniform brick density and structural integrity

- Modular design allowing quick mold changes for multiple brick types and sizes

- Energy-efficient operation with automatic idle shutdown feature

- Integrated vibration technology for superior compaction and reduced material waste

Technical specifications vary by model configuration but typically include these industrial-grade parameters:

| Parameter | Standard Range | Production Impact |

|---|---|---|

| Cycle Time | 15-25 seconds | Enables high-volume output |

| Molding Pressure | 18-32 MPa | Ensures brick durability |

| Power Consumption | 25-55 kW | Optimized energy efficiency |

| Noise Level | <75 dB | Improved workplace environment |

Manufacturing facilities benefit from:

- 45% reduction in manual labor requirements compared to semi-automatic systems

- Consistent product quality with dimensional tolerance within ±0.5mm

- Minimal maintenance requirements with accessible service points

- Compatibility with diverse raw materials including clay, concrete, and fly ash

Backed by Henan Panqi Heavy Industry's manufacturing expertise and global supply chain capabilities, this brick production solution offers exceptional operational longevity with critical components rated for 100,000+ operating cycles. The vibration-dampening frame reduces structural stress while automatic lubrication systems ensure smooth operation during extended production runs. Optional features include remote monitoring interfaces and custom mold development for specialized brick profiles.

Frequently asked questions:

-

What production output can I expect?

Output varies by configuration but standard models produce 8,000-20,000 bricks per 8-hour shift depending on brick dimensions and material composition. -

Are different brick sizes supported?

Yes, the quick-change mold system accommodates various brick dimensions from standard building bricks to specialized pavers. -

What technical support is provided?

We offer comprehensive operational training and troubleshooting documentation with optional on-site commissioning services. -

How energy-efficient is this machinery?

The regenerative hydraulic system recovers up to 30% of energy during decompression cycles, reducing overall power consumption. -

What maintenance is required?

Routine maintenance involves weekly lubrication and quarterly hydraulic fluid checks, with detailed schedules provided.

Optimize your construction material production with machinery engineered for reliability and efficiency in industrial settings. Henan Panqi Heavy Industry supports global clients with customized solutions that enhance manufacturing capabilities while reducing operational costs. Contact our engineering team today for project-specific configuration recommendations and volume production quotations.

With shipping available from multiple Chinese ports and experience serving diverse international markets, we streamline logistics for manufacturing facilities worldwide. Request your personalized equipment proposal to discover how this industrial brick making solution can transform your production economics.

Send Inquiry to This Supplier

You May Also Like

-

2-45 Brick Mold Cement Hollow Brick Concrete Block Making Machine Hollow Cement Paving Machine Block MouldsNegotiableMOQ: 1 Set

-

Professional Brick Making Machine Manufacturer in China With Advanced Technology and Competitive PriceNegotiableMOQ: 1 Set

-

Hot Sale Cement Interlocking Brick Making Machinery Automatic Hollow Concrete Block Making Machine China Brick Machines for Construction JobsUS$ 499 - 2256MOQ: 1 Set

-

Semi-Automatic Portable Brick Making Machine Hollow Concrete Brick Molding Machinery Red Brick Making Machine Best Bricks for House ConstructionUS$ 499 - 2256MOQ: 1 Set

-

China Factory Produces Durable Clay Brick Press Machine With German Standard ComponentsNegotiableMOQ: 1 Set

-

High Efficiency Clay Block Making Machine Hydraulic Pressure Clay Brick Making MachineNegotiableMOQ: 1 Set

-

Small Cement Brick Machine Two Phase Electricity Concrete Pad Machine Shaped Brick Block Forming MachineNegotiableMOQ: 1 Set

-

Fully Automatic Diesel Hydraulic Clay Brick Making Machine for Construction Material ProductionNegotiableMOQ: 1 Set

-

Hot Selling Hollow Brick Electric Hydraulic Red Clay Brick Machine on SaleNegotiableMOQ: 1 Set

-

Eco-Friendly Diesel Engine Hydraulic Pressing Clay Brick Making Machinery for Sustainable BuildingNegotiableMOQ: 1 Set