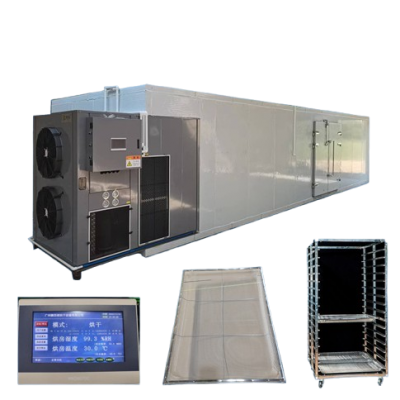

Pharmaceutical Grade Drying Equipment With Precise Moisture Control in Drug Production

Engineered specifically for pharmaceutical manufacturing, our drying equipment delivers uncompromising precision in moisture control during drug production processes. With pharmaceutical-grade stainless steel construction and adaptive control systems, this solution maintains product integrity while meeting stringent industry requirements. Henan Panqi Heavy Industry brings over 4 years of specialized manufacturing expertise to ensure reliability in critical drying applications.

The system's intelligent moisture regulation technology actively prevents batch inconsistencies while optimizing energy efficiency throughout continuous operation cycles.

Key technological advantages include:

Adaptive drying algorithms that automatically adjust parameters based on real-time product analysis

Multi-layer thermal insulation ensuring temperature uniformity within ±1°C across all zones

Redundant sensor arrays providing continuous moisture monitoring at 5-second intervals

Self-diagnostic systems that predict maintenance needs before failures occur

Technical specifications for standard configurations:

Operational benefits for pharmaceutical manufacturers:

Reduces drying cycle times by up to 40% compared to conventional systems

Minimizes product loss through precise endpoint detection

Simplifies validation documentation with automated data logging

Decreases energy consumption through heat recovery mechanisms

Implementing this technology enables consistent compliance with pharmaceutical manufacturing standards while reducing operational costs. The modular design facilitates integration into existing production lines with minimal disruption.

Discover how our drying solutions can enhance your drug manufacturing quality while optimizing production efficiency. Contact our engineering team for application-specific configurations tailored to your exact requirements.

With direct manufacturing capabilities and global logistics support, we provide comprehensive solutions from technical consultation to after-sales service. Our equipment ships worldwide from multiple Chinese ports with flexible commissioning options.

Q: What materials contact the product during drying?

A: All product-contact surfaces utilize 316L stainless steel with electropolished finishes meeting pharmaceutical hygiene standards. Material certificates are provided with equipment documentation.

Q: How is moisture precision maintained across different batch sizes?

A: Our adaptive control system automatically calibrates sensor arrays and adjusts airflow patterns based on real-time load analysis, maintaining precision regardless of batch variations.

Q: What validation support do you provide?

A: We offer comprehensive IQ/OQ documentation packages and can provide protocol templates for PQ activities. System design incorporates features to facilitate validation processes.

Q: Are CIP (Clean-in-Place) systems available?

A: Automated cleaning configurations are optional, designed with spray ball coverage verification and programmable cleaning cycles to meet pharmaceutical sanitation requirements.

Q: What is the typical installation timeframe?

A: Standard installations require 5-7 working days with our supervision. Modular designs minimize on-site assembly time, and detailed installation manuals are provided.

Q: How do you handle overseas technical support?

A: We provide remote diagnostics through secure connections and maintain service partnerships in all major markets for on-site support when required.

Q: Can the system integrate with existing process control networks?

A: Multiple communication protocols (including OPC and Modbus) are supported for seamless integration with facility control systems. Interface customization is available.

Send Inquiry to This Supplier

You May Also Like

-

Portable Vegetable and Fruit Dryer for Camping and Outdoor Activities With Compact SizeNegotiableMOQ: 1 Set

-

Industrial Grade Vegetable and Fruit Dryer Compatible With Food Processing Systems for AgricultureNegotiableMOQ: 1 Set

-

Commercial Vegetable and Fruit Dryer for Horticulture Applications and Large-Scale FarmingNegotiableMOQ: 1 Set

-

Energy-Efficient Vegetable and Fruit Dryer Featuring Low Power Consumption and Digital ControlsNegotiableMOQ: 1 Set

-

User-Friendly Vegetable and Fruit Dryer With Easy Cleaning Features and Durable Material ConstructionNegotiableMOQ: 1 Set

-

Multi-Layer Vegetable and Fruit Dryer With Variable Speed Fans for Efficient DehydrationNegotiableMOQ: 1 Set

-

High-Capacity Vegetable and Fruit Dryer With 15 Tray Design for Large Batch Processing in Food IndustryNegotiableMOQ: 1 Set

-

Fast-Drying Vegetable and Fruit Dryer With Timer and Temperature Settings for Optimal PreservationNegotiableMOQ: 1 Set

-

Stainless Steel Vegetable and Fruit Dryer With Adjustable Shelves and Uniform Drying TechnologyNegotiableMOQ: 1 Set

-

Compact Vegetable and Fruit Dryer Ideal for Home Use and Small Commercial KitchensNegotiableMOQ: 1 Set