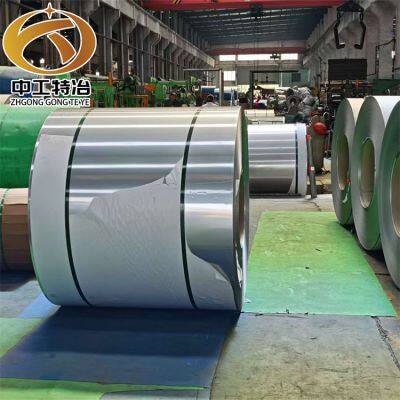

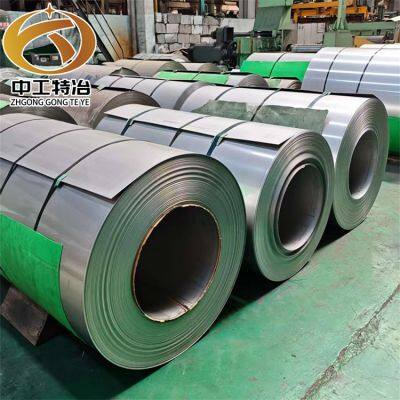

Premium Stainless Steel Coil for Kitchen Equipment and Food Processing Applications

Experience superior performance with our Premium Stainless Steel Coils, specifically engineered for demanding kitchen equipment and food processing applications. These coils combine exceptional corrosion resistance with unmatched hygiene standards, making them the ideal choice for food-safe environments where durability and cleanliness are paramount.

Manufactured using advanced metallurgical processes, our stainless steel coils maintain consistent quality throughout production, ensuring reliable performance in commercial kitchens, food preparation surfaces, processing machinery, and sanitary equipment. The material's inherent resistance to acids, alkalis, and chlorides provides long-term protection against corrosion in challenging food industry environments.

Available in various grades and finishes to match specific application requirements, these coils offer excellent formability for fabrication while maintaining structural integrity. With precise dimensional tolerances and uniform mechanical properties, they streamline manufacturing processes and reduce material waste.

Key Features & Benefits:

✔️ Food-safe surface that inhibits bacterial growth and meets hygiene requirements

✔️ Superior corrosion resistance against food acids, cleaning agents, and moisture

✔️ Excellent thermal stability for equipment exposed to temperature variations

✔️ Easy-to-clean surface that maintains appearance after repeated sanitation

✔️ High strength-to-weight ratio for durable yet lightweight equipment

Technical Specifications:

| Parameter | Specification |

|---|---|

| Material Grades | 304, 304L, 316, 316L (Food Grade Options) |

| Standard Thickness | 0.3mm, 0.4mm, 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm |

| Tensile Strength | 515-720 MPa (Depending on Grade) |

| Yield Strength | 205-310 MPa (Depending on Grade) |

| Elongation | ≥40% (Minimum) |

| Surface Roughness (Ra) | 0.05μm - 0.5μm (Finish Dependent) |

Our stainless steel coils undergo rigorous quality control at every production stage, including:

Chemical composition verification using spectrometry

Mechanical property testing on samples from every batch

Surface quality inspection under controlled lighting

Dimensional accuracy measurements with precision instruments

FAQ Section

Q: What makes your stainless steel suitable for food contact applications?

A: Our coils use 300-series alloys that meet international food safety standards. The material's non-porous surface prevents bacterial penetration and can withstand frequent sanitation without degradation.

Q: Can I request custom dimensions outside your standard range?

A: Yes, we offer custom slitting services to produce widths from 600mm to 1500mm, and thicknesses from 0.3mm to 3.0mm based on your equipment requirements.

Q: What surface finishes do you recommend for kitchen equipment?

A: For food contact surfaces, we recommend 2B finish for general applications or BA (Bright Annealed) finish for superior cleanability. No.4 brushed finish is popular for visible surfaces.

Q: How does your material perform in high-temperature kitchen environments?

A: Our stainless steel maintains structural integrity up to 870°C (intermittent) and 925°C (continuous service), making it suitable for ovens, grills, and other heat-exposed equipment.

Q: What packaging options do you offer for overseas shipment?

A: We provide moisture-resistant wrapping with edge protectors, wooden pallets, and steel strapping to ensure coils arrive undamaged. Special packaging is available upon request.

Q: Do you provide material certification documentation?

A: Yes, we supply Mill Test Certificates (MTC) with each shipment, verifying chemical composition and mechanical properties. Additional certifications are available upon request.

With our global export experience spanning North America, Europe, Asia, and beyond, we understand the unique requirements of international food equipment manufacturers. Our products consistently meet the stringent quality expectations of these markets.

Leverage our technical expertise to select the optimal stainless steel solution for your application. Contact our metallurgical specialists today to discuss your project requirements and request material samples for evaluation.

We offer flexible order quantities with efficient logistics from Shanghai or Tianjin ports, backed by our ISO9001 quality management system. Transform your kitchen equipment manufacturing with reliable stainless steel coils engineered for performance and longevity.

Send Inquiry to This Supplier

You May Also Like

-

China Manufacture Alloy Steel Round Bar 738 1.2738 Stainless Steel BarNegotiableMOQ: 1 Ton

-

China Hot Rolled Black Polished Price ASTM 201/304/316/2205/310S Duplex Alloy Stainless Steel Round BarNegotiableMOQ: 1 Ton

-

Stainless Steel Bar Alloy Rod Stainless Steel J91153 Round Bar Stainless Steel Bar PriceNegotiableMOQ: 1 Ton

-

Cold Work Drawn Alloy Tool Stainless Steel HSS Round Bar Best Quality Steel Round Bar 440B Stainless Steel BarNegotiableMOQ: 1 Ton

-

1.4301 Fishing Rod ASTM A276 420 Stainless Steel Round Bar Alloy Steel BarNegotiableMOQ: 1 Ton

-

Inox Metal Rod Hot Rolled Alloy Steel Round Bars High Quality 304 316 Stainless Steel Round Bars 2mm 3mm Metal Rod PriceNegotiableMOQ: 1 Ton

-

Ss Rod 321 316 304 430 2205 2507 Alloy Steel Bar 10-300mm Diameter Stainless Steel Rod Price for Building ConstructionNegotiableMOQ: 1 Ton

-

Stainless Steel 304 S30400 SUS304 Round Steel Hot Rolling Steel BarNegotiableMOQ: 1 Ton

-

Hot Sale Customized Stainless Steel 304 304L 316 316L Bright Polished BA Bar for Construction and IndustryNegotiableMOQ: 1 Ton

-

Round Stainless Steel Rod High Quality 1cr18ni9ti 321 310s 304 Stainless Steel BarNegotiableMOQ: 1 Ton