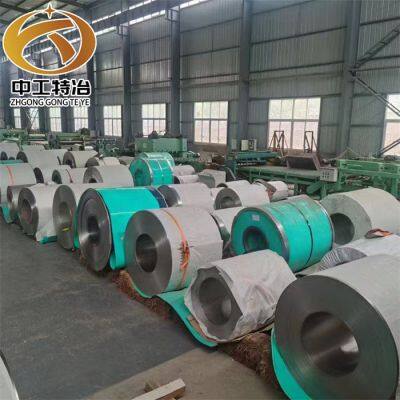

Corrosion-Resistant Stainless Steel Coil Offering High Durability in Harsh Environments

Engineered for resilience in demanding conditions, our corrosion-resistant stainless steel coils deliver exceptional performance where ordinary metals fail. Manufactured by Jiangsu Zhonggongte Metallurgical Technology, these coils combine advanced metallurgical expertise with rigorous quality control to provide reliable protection against corrosive elements. Ideal for critical applications across multiple industries, this product offers substantial cost savings through extended service life and reduced maintenance requirements.

With ISO9001 certification and global export experience spanning over 100 countries, we ensure consistent quality that meets international standards. Our coils maintain structural integrity in saltwater environments, chemical processing plants, and extreme weather conditions – providing peace of mind for engineers and procurement specialists alike.

Key Technical Specifications:

| Parameter | Specification |

|---|---|

| Material Grades | 304, 316, 430, 201 (customizable) |

| Tensile Strength | 515-860 MPa (grade dependent) |

| Elongation at Break | ≥40% (minimum) |

| Surface Hardness | HRB 65-90 (custom temper available) |

| Salt Spray Resistance | 1,000+ hours without red rust |

Performance Advantages:

Superior corrosion resistance - chromium-nickel composition creates passive oxide layer that self-repairs

Reduced lifecycle costs - withstands pitting, crevice corrosion, and stress corrosion cracking

Temperature tolerance from -200°C to 800°C without degradation

Multiple surface finishes available for specific application requirements

Consistent gauge control (±0.02mm tolerance) ensures manufacturing precision

Our manufacturing process includes continuous annealing and pickling for optimal surface quality, followed by precise tension leveling to ensure flatness. Each coil undergoes non-destructive testing including:

• Eddy current testing for surface defects

• Ultrasonic thickness verification

• Spectrometer analysis for alloy composition

Industry Applications:

Chemical Processing: Reactor linings, piping systems, storage tanks

Marine Engineering: Shipbuilding components, offshore platforms, desalination plants

Construction: Coastal infrastructure, structural elements in corrosive environments

Food Processing: Hygienic surfaces requiring frequent sanitation

Energy Sector: Flue gas desulfurization systems, heat exchangers

Global clients benefit from our streamlined logistics network with shipment options from Shanghai, Tianjin, and inland ports. With annual exports exceeding $100 million and established operations across six continents, we deliver reliably to North America, Europe, Asia, Africa, and Oceania. Custom packaging solutions including waterproof wrapping and edge protection ensure coils arrive in pristine condition.

Beyond standard specifications, we offer technical support for material selection based on your specific environmental challenges. Our metallurgical experts can advise on grade selection for unique combinations of temperature, chemical exposure, and mechanical stress factors.

Frequently Asked Questions:

Q: What distinguishes your corrosion-resistant coils from standard stainless steel?

A: Our coils undergo specialized processing including controlled annealing temperatures and advanced pickling techniques that enhance the passive layer formation. This creates superior resistance to chlorides and acidic environments compared to standard stainless products.

Q: Can you provide coils with non-standard dimensions?

A: Yes, we regularly manufacture coils with custom widths, thicknesses, and inner/outer diameters to meet specific project requirements. Minimum order quantities apply for custom dimensions.

Q: What is the typical lead time for orders?

A: Standard specifications ship within 15-25 days. Custom orders require 30-45 days for production. Expedited processing may be available for urgent requirements.

Q: Do you provide material test certificates?

A: Yes, each shipment includes a 3.1 mill certificate detailing chemical composition, mechanical properties, and surface quality verification. Additional testing reports are available upon request.

Q: How do you ensure consistent quality across large orders?

A: Our automated production lines feature real-time monitoring systems, and we implement statistical process control with batch sampling. ISO9001-certified quality management covers all manufacturing stages.

Ready to enhance your project's durability?

With over 51-100 specialized staff and established overseas offices, Jiangsu Zhonggongte provides responsive support from initial inquiry through after-sales service. Our technical team can help optimize material selection for your specific environmental challenges.

Contact us today for volume pricing, custom specifications, or to request sample materials. Experience the difference that professionally engineered corrosion resistance makes in extending equipment lifespan and reducing maintenance costs.

Global reach, specialized materials, proven performance – partner with us for your critical applications.

Send Inquiry to This Supplier

You May Also Like

-

Cold Work Drawn Alloy Tool Stainless Steel HSS Round Bar Best Quality Steel Round Bar 440B Stainless Steel BarNegotiableMOQ: 1 Ton

-

1.4301 Fishing Rod ASTM A276 420 Stainless Steel Round Bar Alloy Steel BarNegotiableMOQ: 1 Ton

-

Inox Metal Rod Hot Rolled Alloy Steel Round Bars High Quality 304 316 Stainless Steel Round Bars 2mm 3mm Metal Rod PriceNegotiableMOQ: 1 Ton

-

Ss Rod 321 316 304 430 2205 2507 Alloy Steel Bar 10-300mm Diameter Stainless Steel Rod Price for Building ConstructionNegotiableMOQ: 1 Ton

-

Stainless Steel 304 S30400 SUS304 Round Steel Hot Rolling Steel BarNegotiableMOQ: 1 Ton

-

Hot Sale Customized Stainless Steel 304 304L 316 316L Bright Polished BA Bar for Construction and IndustryNegotiableMOQ: 1 Ton

-

Round Stainless Steel Rod High Quality 1cr18ni9ti 321 310s 304 Stainless Steel BarNegotiableMOQ: 1 Ton

-

Alloy F62 926 N08367 Bright Rod, Stainless Steel Rod, Corrosion Resistant and Oxidation ResistantNegotiableMOQ: 1 Ton

-

Super Austenitic Stainless Steel CN3MN AL6XN Stainless Steel Rod Can be CustomizedNegotiableMOQ: 1 Ton

-

Supply Wholesale Price Stainless Steel Sheet/Plate ASTM A240 AISI 304 321 316L, 310S, 439 ManufacturerNegotiableMOQ: 1 Ton