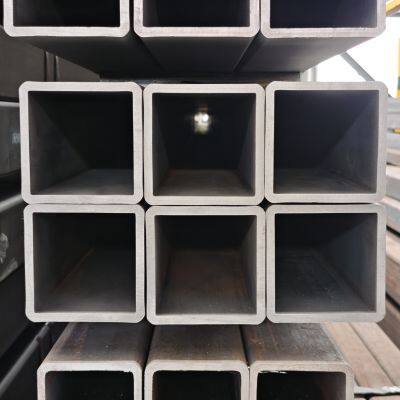

Precision-Made Seamless Square Steel Pipe Ideal for Machinery and Equipment Manufacturing Needs

Engineered for excellence, our precision seamless square steel pipe delivers unmatched structural integrity for demanding machinery and equipment manufacturing applications. Crafted through advanced cold-drawn processes, these pipes eliminate weak points while maintaining dimensional accuracy within ±0.1mm tolerances. Manufacturers globally trust our solution to enhance load-bearing capacity and reduce maintenance costs in industrial systems.

Key advantages include:

- Zero weld seams preventing corrosion initiation points

- Superior concentricity ensuring uniform wall thickness

- High torsional strength for dynamic operational environments

- Custom chemical compositions available upon request

Technical specifications vary based on application requirements, with standard parameters including:

| Parameter | Range | Standard |

|---|---|---|

| Cross-Section | 10x10mm to 250x250mm | ASTM A500 |

| Wall Thickness | 1.0mm - 20mm | EN 10210 |

| Tensile Strength | ≥415 MPa | ISO 6892-1 |

For equipment manufacturers, these pipes offer critical benefits: Reduced vibration in transmission systems, increased fatigue resistance in robotic arms, and simplified assembly through consistent dimensional stability. Surface treatments including phosphating or galvanization extend service life in corrosive environments while maintaining precise tolerances. Our vertically integrated production ensures strict quality control at every stage – from billet selection to final inspection – guaranteeing compliance with international standards.

Optimize your manufacturing outcomes with steel tubing that combines precision engineering with industrial durability. Contact our technical team for material certifications and custom dimension solutions tailored to your machinery specifications. With ISO-certified manufacturing and global logistics support, we deliver reliability that integrates seamlessly into your production workflow.

Frequently Asked Questions

-

Q: What materials are used in production?

A: We primarily utilize carbon steel grades (e.g., 20#, 45#) with alloy options customizable for specific strength requirements. -

Q: Can I request non-standard sizes?

A: Yes, our production facilities accommodate custom dimensions between 10x10mm and 250x250mm with wall thickness adjustments. -

Q: How do seamless pipes outperform welded alternatives?

A: The absence of welds eliminates structural weaknesses, improving pressure resistance and fatigue performance in dynamic applications. -

Q: What surface protections are available?

A: Options include oil coating, galvanization, or painting – specified during ordering to match operational environments. -

Q: What certifications support quality claims?

A: Our manufacturing processes hold ISO9004 and ISO14000 certifications, with material test reports provided upon request. -

Q: How does this product enhance machinery manufacturing?

A: Precision dimensions ensure component interoperability, while seamless construction reduces vibration in moving parts. -

Q: What packaging standards do you follow?

A: We use weather-resistant bundling with corner protectors, customizable for export requirements.

Send Inquiry to This Supplier

You May Also Like

-

Eco-Friendly Seamless Square Steel Pipe With Long Lifespan for Sustainable Building ProjectsNegotiableMOQ: 1 Ton

-

High Strength 100x100 150x150 Seamless Square Steel Pipe, Main Support Column for Warehouse and Plant StructureNegotiableMOQ: 1 Ton

-

Seamless Square Steel Pipe Available in Sizes 10x10mm to 100x100mm for Custom Industrial ApplicationsNegotiableMOQ: 1 Ton

-

Hollow Section Square Tube in Stock Cold Drawn Square Seamless Steel Pipe China SupplierNegotiableMOQ: 1 Ton

-

China Factory Mild Steel Square Tube Carbon Steel Black Mild Carbon Steel TubesNegotiableMOQ: 1 Ton

-

Discount Price Seamless Alloy Square Steel Tube 50x50mm Cold Drawn Steel PipeNegotiableMOQ: 1 Ton

-

China Steel Cold Drawn Square Steel Tube High Performance Seamless Square Steel PipeNegotiableMOQ: 1 Ton

-

High Quality 20# Square Steel Tube Hollow Tube Square Pipe Cold Drawn Seamless TubeNegotiableMOQ: 1 Ton

-

China Q690D Square Tube Seamless Round Steel Pipe Free SampleNegotiableMOQ: 1 Ton

-

Agricultural Machinery Square Steel Tube Hollow Seamless Pipe Made in ChinaNegotiableMOQ: 1 Ton