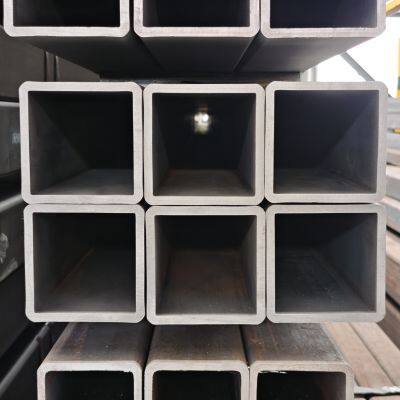

Seamless Square Steel Pipe Designed for Oil and Gas Pipeline Systems With Various Wall Thickness

Engineered specifically for demanding oil and gas pipeline applications, our seamless square steel pipe delivers unmatched structural integrity and reliability. With customizable wall thickness options, this pipe ensures optimal performance in high-pressure environments while maintaining flow efficiency. Manufactured by Hunan Yige Special Steel since 2015, it combines advanced production techniques with rigorous ISO9004 and ISO14000 certified quality control processes.

Core Technical Advantages:

- Seamless construction eliminates weld weaknesses and prevents leakage points

- Precision-engineered square profile enhances structural stability in pipeline networks

- Variable wall thickness (1.5mm-25mm) accommodates different pressure requirements

- Superior corrosion resistance through optional protective coatings

- Material composition optimized for cryogenic to high-temperature operations

Standard Specifications Table

| Parameter | Specification |

|---|---|

| Material Grade | ASTM A53/A106 or equivalent |

| Standard Size Range | 20mm x 20mm to 300mm x 300mm |

| Length Options | 6m / 12m standard (customizable) |

| Hydrostatic Test Pressure | Up to 30MPa (adjustable) |

These pipes feature enhanced mechanical properties including minimum yield strength of 240MPa and tensile strength of 415MPa, ensuring reliable performance in subsurface and aboveground installations. The seamless manufacturing process guarantees uniform wall thickness distribution, significantly reducing turbulence and erosion in fluid transport applications. Customized solutions are available for specialized pipeline configurations including offshore platforms and arctic environments.

Operational Benefits:

- 40% longer service life compared to welded alternatives

- Reduced maintenance costs through superior corrosion resistance

- Compatibility with standard pipeline connection systems

- Enhanced safety margins in high-pressure operations

Backed by our 9,000m² manufacturing facility and global distribution network spanning North America, Europe, Asia, and Africa, we ensure timely delivery of consistent quality products. Our technical team provides comprehensive support from material selection to installation guidance, helping optimize your pipeline system's performance and longevity.

Frequently Asked Questions

Q: What pressure ratings do these pipes support?

A: Pressure capacity ranges from 15-30MPa depending on wall thickness selection and material grade.

Q: Are custom sizes available?

A: Yes, we manufacture pipes according to client specifications including non-standard dimensions.

Q: What surface treatments are offered?

A: Options include black painting, galvanization, epoxy coating, or as per project requirements.

Q: What is the typical lead time for orders?

A: Standard configurations ship in 15-30 days; custom projects may require additional production time.

Q: Do you provide material test certificates?

A: Yes, certified mill test reports are available for every production batch.

Q: How do these pipes perform in corrosive environments?

A: Carbon steel composition with optional coatings provides excellent resistance to H2S, CO2, and saltwater corrosion.

Discover how our seamless square steel pipes can enhance your pipeline system's reliability and efficiency. Contact our engineering team today for project-specific quotations and technical consultations tailored to your oil and gas infrastructure requirements. With ISO-certified manufacturing and global logistics capabilities, we deliver solutions that meet the most demanding industry standards.

Send Inquiry to This Supplier

You May Also Like

-

Hollow Section Square Tube in Stock Cold Drawn Square Seamless Steel Pipe China SupplierNegotiableMOQ: 1 Ton

-

China Factory Mild Steel Square Tube Carbon Steel Black Mild Carbon Steel TubesNegotiableMOQ: 1 Ton

-

Discount Price Seamless Alloy Square Steel Tube 50x50mm Cold Drawn Steel PipeNegotiableMOQ: 1 Ton

-

China Steel Cold Drawn Square Steel Tube High Performance Seamless Square Steel PipeNegotiableMOQ: 1 Ton

-

High Quality 20# Square Steel Tube Hollow Tube Square Pipe Cold Drawn Seamless TubeNegotiableMOQ: 1 Ton

-

China Q690D Square Tube Seamless Round Steel Pipe Free SampleNegotiableMOQ: 1 Ton

-

Agricultural Machinery Square Steel Tube Hollow Seamless Pipe Made in ChinaNegotiableMOQ: 1 Ton

-

35CrMo Square Steel Tube Seamless Profile Pipes Cold Drawn Round Tubes Professional ManufacturerNegotiableMOQ: 1 Ton

-

Hot Sale SCH40 Hollow Round Square Tube Seamless Cold Drawn Carbon Steel Pipes PricelistNegotiableMOQ: 1 Ton

-

Hollow Section SCH80 Square Steel Pipe Seamless Rectangular Steel Pipes From ChinaNegotiableMOQ: 1 Ton