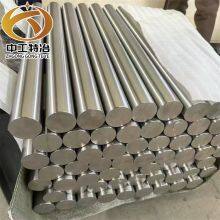

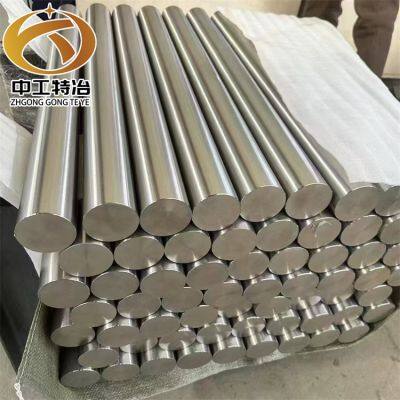

Cobalt Based Alloy Rod for High-Temperature Welding and Aerospace Components

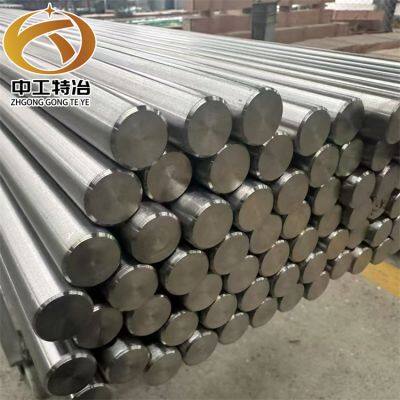

Discover our premium Cobalt Based Alloy Rod, meticulously engineered for high-performance applications in extreme environments such as high-temperature welding and aerospace components. This alloy rod delivers unparalleled reliability and durability, making it an essential choice for industries demanding precision and resilience. With its superior heat and corrosion resistance, it enhances welding efficiency and extends the lifespan of critical parts, reducing maintenance costs. Backed by rigorous quality standards, it represents a smart investment for professionals seeking dependable solutions. Partner with us to elevate your operational excellence and achieve consistent results in challenging settings.

Our alloy rod stands out for its exceptional properties, tailored to meet the rigorous demands of modern manufacturing and aerospace engineering. Let’s delve into the detailed features and benefits that make this product a standout choice.

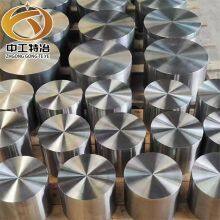

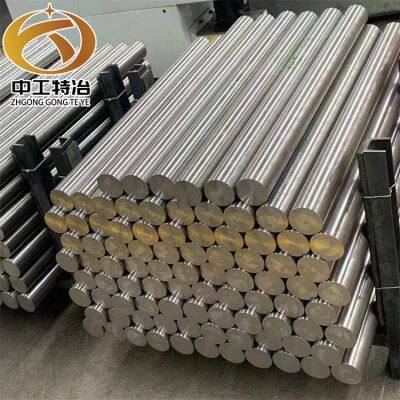

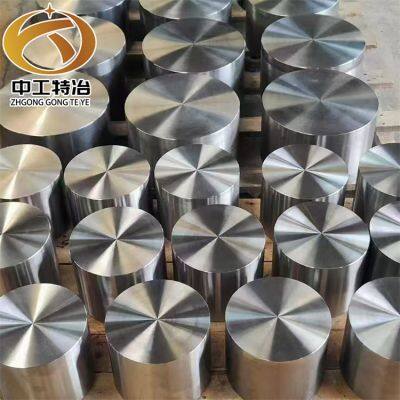

Key Characteristics: The rod boasts high-temperature stability up to 1400°C, excellent mechanical strength, and resistance to oxidation and wear. Its cobalt-based composition ensures minimal deformation under stress, ideal for precision welding and component fabrication.

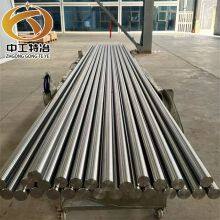

Technical Specifications: Below is a comprehensive table outlining core parameters. Note that specifications can be adjusted based on customer requirements to suit specific applications.

| Parameter | Value | Description |

|---|---|---|

| Diameter | 1mm - 50mm | Available in standard sizes; customizable options available |

| Length | 1m - 6m | Adjustable to project needs for optimal handling |

| Composition | Co: 55-60%, Cr: 25-30% | Balanced alloy for enhanced performance |

| Melting Point | ~1400°C | Suitable for high-heat applications |

| Density | 8.5 g/cm³ | Ensures lightweight yet robust construction |

The advantages of this cobalt-based alloy rod extend beyond its technical specs. It offers significant benefits for end-users, such as reducing downtime in welding operations by providing consistent arc stability and minimizing slag formation. In aerospace contexts, it contributes to lighter, stronger components that withstand thermal cycling, ultimately lowering lifecycle costs. Additionally, its corrosion resistance makes it versatile for secondary industries like power generation or chemical processing. For custom specifications, we provide tailored solutions to align with unique project demands, ensuring seamless integration into your workflows.

As a trusted supplier, Jiangsu Zhonggongte Metallurgical Technology leverages its global network to support your success. Reach out to explore how this product can optimize your processes and drive efficiency.

Embrace innovation with our alloy rod—contact us today for a consultation or to place an order. We guarantee responsive service and reliable delivery to help you achieve superior outcomes.

Frequently Asked Questions (FAQ)Q: What are the primary uses of this cobalt-based alloy rod?

A: It is primarily designed for high-temperature welding applications and aerospace components, such as turbine blades or exhaust systems, where heat resistance and durability are critical.Q: Can the rod be customized for specific sizes or shapes?

A: Yes, dimensions like diameter and length are customizable upon request to match your project requirements, ensuring optimal fit and performance.Q: What certifications support the quality of this product?

A: The rod is ISO9001 certified, guaranteeing adherence to international quality management standards for consistency and reliability.Q: How does the alloy perform in corrosive environments?

A: With inherent corrosion resistance, it excels in harsh conditions, such as chemical exposure or marine settings, reducing degradation over time.Q: What shipping options are available for international orders?

A: We ship from ports like Shanghai and Tianjin, with flexible logistics to major markets including North America, Europe, and Asia, ensuring timely delivery.Q: Is this rod suitable for industries outside aerospace and welding?

A: Absolutely, it can be adapted for medical devices, automotive parts, or energy sectors, offering versatility for diverse high-stress applications.Q: What is the typical lead time for orders?

A: Lead times vary based on customization but generally range from 2-4 weeks; contact us for specific estimates to plan efficiently.

Send Inquiry to This Supplier

You May Also Like

-

Hastelloy C276 Alloy Plate for Chemical Reactor Manufacturing - Corrosion Resistant Industrial Sheet SupplierNegotiableMOQ: 1 Ton

-

Industrial Grade Hastelloy C276 Alloy Plate Sheet for Marine Environments and Offshore Rig ComponentsNegotiableMOQ: 1 Ton

-

High Strength Corrosion Resistant Alloy Sheet for Power Generation Equipment ManufacturerNegotiableMOQ: 1 Ton

-

Nickel-Chromium-Molybdenum Hastelloy C276 Alloy Plate Sheet With Excellent Weldability FeaturesNegotiableMOQ: 1 Ton

-

Corrosion-Resistant Hastelloy C276 Alloy Plate Sheet for Chemical Processing Equipment ApplicationsNegotiableMOQ: 1 Ton

-

Custom Size Hastelloy B3 Alloy Plate for Highly Reducing Corrosive Environments Factory SupplyNegotiableMOQ: 1 Ton

-

Versatile Hastelloy C276 Alloy Plate Sheet Compatible With Power Generation and Petrochemical SystemsNegotiableMOQ: 1 Ton

-

High Performance Alloy Steel Plate for Heat Exchanger and Reactor Production FactoryNegotiableMOQ: 1 Ton

-

Hastelloy C276 Alloy Plate Sheet in Standard Sizes From 1mm to 50mm Thickness for Industrial UseNegotiableMOQ: 1 Ton

-

Superior Corrosion Resistance Hastelloy Alloy Bar for Harsh Environmental and High-Temperature UseNegotiableMOQ: 1 Ton