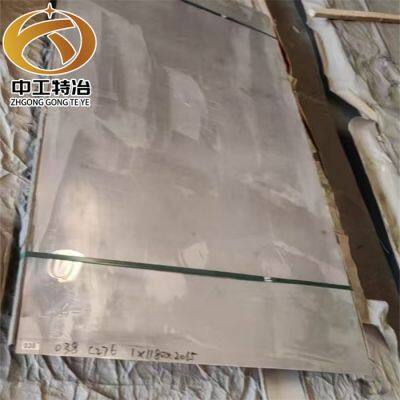

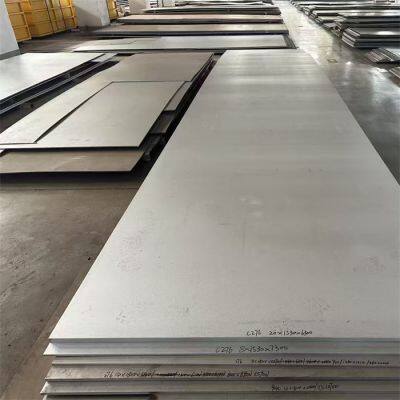

Industrial Grade Hastelloy C276 Alloy Plate Sheet for Marine Environments and Offshore Rig Components

Engineered for extreme marine corrosion resistance, our Industrial Grade Hastelloy C276 Alloy Plate Sheet delivers unmatched performance in offshore and seawater applications. This nickel-molybdenum-chromium superalloy maintains structural integrity in chloride-rich environments where standard stainless steels fail. With proven resistance to pitting, crevice corrosion, and stress corrosion cracking, it's the material of choice for critical marine infrastructure.

Manufactured under ISO9001-certified processes, these plates combine exceptional durability with consistent metallurgical properties. The alloy's unique composition provides stability across temperatures from -196°C to 400°C, making it suitable for subsea components and topside equipment alike. Reduced maintenance costs and extended service life provide significant operational savings over traditional materials.

Mechanical Properties:

Tensile Strength: ≥690 MPa

Yield Strength (0.2% offset): ≥283 MPa

Elongation: ≥40%

Hardness: ≤100 HRB

Key Applications in Marine & Offshore:

Seawater piping systems and heat exchangers

Subsea manifolds and Christmas tree components

Flue gas desulfurization systems

Ballast water treatment equipment

Offshore platform structural reinforcements

Chemical cargo tanks and processing vessels

The material's exceptional weldability allows for complex fabrication without post-weld heat treatment. Our plates undergo rigorous non-destructive testing including ultrasonic examination to ensure defect-free surfaces and consistent thickness tolerances per ASTM B575 standards. Custom cutting, beveling, and machining services are available upon request.

Packaging & Logistics:

Wooden crates with waterproof wrapping

Edge protection for transit safety

Export documentation included

Flexible shipment from Shanghai/Tianjin ports

With over $100 million annual export experience, we guarantee on-time delivery to global destinations. Partner with our metallurgical specialists to specify the optimal grade and dimensions for your marine engineering challenge. Request material test reports or sample certifications for project validation.

Frequently Asked Questions:

Q: What makes C276 superior to 316L stainless in seawater?

A: C276 offers 100x greater resistance to chloride-induced pitting and crevice corrosion compared to 316L, particularly in stagnant or low-flow seawater conditions.

Q: Can these plates withstand sour gas environments?

A: Yes, C276 maintains corrosion resistance in H₂S-containing environments up to 204°C per NACE MR0175 standards.

Q: What welding methods are recommended?

A: GTAW (TIG) and GMAW (MIG) using matching filler metals yield optimal results. Detailed welding procedure specifications are provided.

Q: Do you offer anti-slip surface treatments?

A: Diamond plate patterns and specialized coatings are available upon request for decking applications.

Q: What documentation accompanies shipments?

A> All orders include Material Test Certificates per EN 10204 3.1, chemical analysis reports, and origin certification.

Q: Can I get custom-sized cut plates?

A> Plasma, laser, and waterjet cutting services are available with ±1mm dimensional tolerance.

Contact our technical team with specific alloy requirements or request a corrosion resistance comparison chart for your operating conditions. Protect your offshore investments with metallurgically verified C276 solutions – inquire about volume discounts for drilling platform projects today.

Send Inquiry to This Supplier

You May Also Like

-

High Performance Alloy Steel Plate for Heat Exchanger and Reactor Production FactoryNegotiableMOQ: 1 Ton

-

Hastelloy C276 Alloy Plate Sheet in Standard Sizes From 1mm to 50mm Thickness for Industrial UseNegotiableMOQ: 1 Ton

-

Superior Corrosion Resistance Hastelloy Alloy Bar for Harsh Environmental and High-Temperature UseNegotiableMOQ: 1 Ton

-

Custom Size Hastelloy Alloy Bar Compatible With Aerospace Components for Long-Term DurabilityNegotiableMOQ: 1 Ton

-

Professional Hastelloy C-22 Stock Factory With Stock Chinese Factory Supply for Industrial ApplicationsNegotiableMOQ: 1 Ton

-

China Hastelloy B-3 Alloy Round Bar for High-Temperature Hydrochloric Acid Service EquipmentNegotiableMOQ: 1 Ton

-

Pharmaceutical Grade Hastelloy C-22 Round Bar for Sterile Equipment in Medical and Laboratory SettingsNegotiableMOQ: 1 Ton

-

High-Quality Hastelloy C-22 Round Bar Supplier for Aerospace Component ProductionNegotiableMOQ: 1 Ton

-

Hastelloy C-276 Alloy Round Bar Manufacturer for Chemical Processing Equipment Reliable Hastelloy Alloy Production FactoryNegotiableMOQ: 1 Ton

-

Hastelloy C276 Alloy Bar With High Strength and Acid Resistance for Critical Engineering ProjectsNegotiableMOQ: 1 Ton