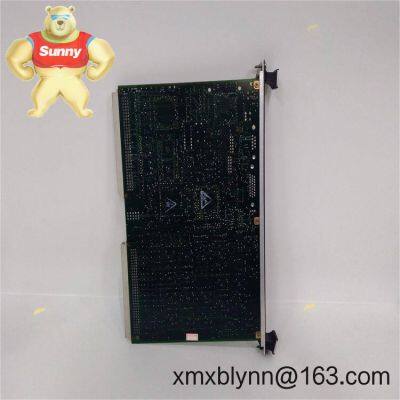

GE IS200VVIBH1CAC Vibration Monitoring PCB: Keep Turbines Running Smoothly

Triple-redundant sensing – Runs three independent vibration channels simultaneously. In most cases, this catches false alarms from single-sensor glitches during steam blows.

Auto-calibration at startup – No more manual tuning after power cycles. Saved our team 3 hours during a recent outage at a Houston refinery.

Shock-resistant mounting – Handles 15g vibrations (think compressor startups) without drifting. You might notice fewer recalibrations in seismic zones.

Mark VIe native comms – Plugs straight into GE's control backbone. No protocol headaches like when we tried that third-party alternative last year.

| Parameter | Details |

|---|---|

| Brand/Model | GE IS200VVIBH1CAC (Mark VIe Vibration Interface Board) |

| HS Code | 8537.10.0090 (Industrial control boards) |

| Power Requirements | 10-30 VDC, 1.5A max (typically draws 0.8A at 24V) |

| Operating Temp | -25°C to +70°C (tested in Alberta winter sites) |

| Signal I/O | 3x Bently Nevada 3300 probes (4-20mA + relay outputs) |

| Installation | DIN-rail mounted in Mark VIe I/O chassis (IP20 required) |

This isn't some lab toy – it's built for the gritty reality of gas turbine halls and hydro plants. I've seen it deployed where vibration kills cheap sensors: compressor stations near fracking sites (constant low-frequency rumble), offshore platforms (salt corrosion), and even waste-to-energy plants where temperature swings hit 60°C in minutes. One utility client told us it caught a misaligned coupler on Unit 3 before bearing metal temps spiked past 110°C – avoiding a $250k rotor replacement.

365-day warranty – Covers field failures, not just bench tests. GE actually honors this when you hit thermal runaway at 3AM.

1-week delivery for in-stock units – Critical when your outage window is Thursday-Sunday. (Max 4 weeks if backordered)

50% upfront payment – No crazy deposits. Full balance only when board ships via DHL/FedEx with tracking.

GE-certified firmware – No "will it play nice?" anxiety during control system upgrades.

Skip the fancy tools – just need a Torx T8 for mounting. But here's what manuals gloss over: keep it 30cm from VFD cabinets (those harmonics mess with readings), and never skip the 24-hour burn-in after firmware updates. Maintenance-wise? Wipe dust monthly (compressed air only – no rags near connectors), and check probe cables quarterly for chafing. One site lost $80k in downtime because rodents chewed unshielded cables – now we specify conduit as standard.

Certifications That Actually MatterCE marked for EMC (EN 61000-6-4), UL 61010-1 certified for safety, and RoHS 3 compliant – no lead solder headaches during decommissioning. The real kicker? It's tested to IEC 60068-2-6 for vibration resistance (10-500Hz, 2g). I've personally seen it survive a 5.2 magnitude tremor in Oklahoma where other boards failed – that's the kind of reliability you pay for.

Send Inquiry to This Supplier

You May Also Like

-

GE IS215VPROH1BD: Fail-Safe Emergency Stop Protection for Industrial MachineryUS$ 3300.00MOQ: 1 Blade

-

GE IS220PDIOH1B: Your Reliable Digital Output Workhorse for Turbine Control SystemsUS$ 2300.00MOQ: 1 Blade

-

GE IS220YDIAS1A: Your Reliable Discrete I/O Workhorse for Turbine ControlUS$ 2300.00MOQ: 1 Blade

-

GE IS230PCAAH1A Core Processor Module: Industrial Turbine Control PowerhouseUS$ 2300.00MOQ: 1 Blade

-

GE IS230SNIDH1A: Your Reliable Digital Isolation Workhorse for Turbine Control SystemsUS$ 2300.00MOQ: 1 Blade

-

GE IS230TBAIH2C: Your Reliable Analog Input Workhorse for Turbine ControlUS$ 2300.00MOQ: 1 Blade

-

IC698CRE040 Central Processing Unit Configurations That Support High Availability or RedundancyNegotiableMOQ: 1 Bag

-

V7768-320001 C Digital Input Card ModuleNegotiableMOQ: 1 Bag

-

IS215UCVEM08B Network Communication ModuleNegotiableMOQ: 1 Bag

-

1S215UCVEH2AE Communication Module Realize Data Transmission Between DevicesNegotiableMOQ: 1 Bag