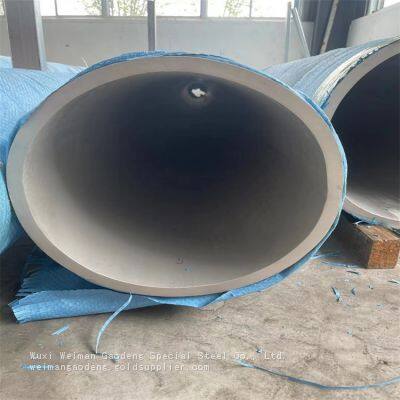

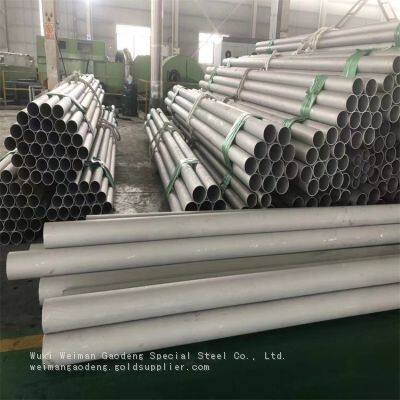

Dimensional Stable Heat Resistant Tubes, 1.4307 & S30453 Ferritic Stainless Steel Boiler Tubes

We specialize in manufacturing high-performance seamless steel tubes and alloy steel tubes, covering a full range of materials including austenitic, ferritic, and super alloy grades. Our products are engineered for high-temperature, high-pressure, and corrosive environments, widely used in boilers, heat exchangers, and industrial superheaters, delivering reliable performance for critical industrial applications.

Core Material Specifications1. Austenitic Stainless Steel Tubes

Material Grade | Corresponding Standards | Key Properties |

304/S30400/1.4301 | ASTM A213/A480 | Excellent corrosion resistance, good weldability |

304H/S30409/1.4948 | ASTM A213 | High-temperature strength, stable structure at 800-900℃ |

304L/S30403/1.4307 | ASTM A213 | Low carbon content, anti-intergranular corrosion |

304LN/S30453/1.4311 | ASTM A213 | Nitrogen-enhanced, improved strength and toughness |

Super304/S30432 | ASTM A213 | High chromium-nickel content, superior high-temperature oxidation resistance |

321/S32100/1.4541 | ASTM A213 | Titanium-stabilized, anti-sensitization at high temperatures |

321H/S32109/1.4940 | ASTM A213 | High-temperature tolerance, suitable for 900-1000℃ service |

316L/S31603/1.4404 | ASTM A213 | Molybdenum-added, enhanced corrosion resistance to chloride media |

316LN/S31653/1.4406 | ASTM A213 | Nitrogen alloyed, improved creep strength |

316Ti/S31635/1.4571 | ASTM A213 | Titanium-stabilized, excellent resistance to high-temperature corrosion |

317L/S31703/1.4438 | ASTM A213 | Higher molybdenum content, superior pitting corrosion resistance |

310S/S31008/1.4845 | ASTM A213 | High chromium-nickel (25Cr-20Ni), resistant to 1100℃ high temperature |

347H/S34709/1.4942 | ASTM A213 | Niobium-stabilized, good creep resistance at high temperatures |

347HFG/S34710 | ASTM A213 | Fine-grained structure, enhanced fatigue resistance |

2. Ferritic Stainless Steel Tubes

Material Grade | Corresponding Standards | Key Properties |

314/1.4841 | ASTM A213 | High chromium content, excellent oxidation resistance at high temperatures |

310HCbN/S31042 | ASTM A213 | Niobium and nitrogen alloyed, improved high-temperature strength |

3. Super Alloy & Special Steel Tubes

Material Grade | Corresponding Standards | Key Properties |

904L/N08904/1.4539 | ASTM B677 | High nickel-molybdenum-copper, resistant to strong corrosive media |

S31254/1.4547 | ASTM A240 | Super austenitic, superior pitting and crevice corrosion resistance |

N08367 | ASTM B668 | Low carbon, high corrosion resistance to sulfuric acid and phosphoric acid |

N08926/1.4529 | ASTM B670 | Duplex stainless steel, balanced strength and corrosion resistance |

S32654/1.4652 | ASTM A240 | Ultra-super austenitic, excellent resistance to harsh corrosive environments |

310MoLN/S31050/1.4466 | ASTM A213 | Molybdenum and nitrogen enhanced, improved high-temperature corrosion resistance |

316LMoD/316LUG/1.4435 | ASTM A213 | Modified molybdenum content, suitable for ultra-low temperature and corrosive conditions |

Product Advantages

• Precision Dimensional Control: Adopt cold drawing and hot rolling processes, ensuring tight tolerance of outer diameter (±0.05mm) and wall thickness (±0.02mm), meeting strict assembly requirements.

• Superior Mechanical Properties: High tensile strength (≥515MPa), excellent elongation (≥40%), and good impact toughness even at low temperatures (-196℃ for 904L).

• Excellent Corrosion & High-Temperature Resistance: Resistant to oxidation, pitting, and intergranular corrosion; applicable for long-term service in high-temperature environments up to 1100℃ (310S grade).

• Smooth Surface & Inner Wall: Surface finish up to Ra≤0.8μm, inner wall free of burrs, reducing fluid resistance and preventing material accumulation.

• Dimensional Stability: Low thermal expansion coefficient, minimal deformation under temperature fluctuations, ensuring long-term operational reliability.

Application Scenarios

• Boiler & Superheater Systems: Boiler tubes and superheater tubes for power plants, suitable for high-temperature and high-pressure steam environments (321H, 347H, 310S grades).

• Heat Exchangers: Heat exchanger tubes for chemical, petrochemical, and refrigeration industries, resisting corrosive media (316L, 317L, 904L grades).

• High-Temperature Industrial Equipment: Tubes for furnaces, kilns, and thermal processing equipment (310S, 314, Super304 grades).

• Corrosive Environment Applications: Chemical pipelines, marine engineering, and offshore oil platforms (S31254, N08926, S32654 grades).

• General Industrial Fields: Fluid transportation, structural support, and mechanical parts manufacturing (304, 304L, 316L grades).

Processing & Customization Capabilities

• Size Range: Outer diameter: 6mm-219mm; Wall thickness: 0.8mm-20mm; Length: 1m-12m (customizable for special lengths).

• Processing Technologies: Hot rolling, cold drawing, bright annealing, pickling passivation, sandblasting, and precision cutting.

• Surface Treatments: Annealed, pickled, polished (2B, BA, 8K), and anti-corrosion coating (customizable based on requirements).

• Custom Services: Provide non-standard size customization, material modification, and pre-assembly processing according to customer drawings and technical specifications.

Quality Assurance

• Certifications: Product certifications conforming to ASTM, ASME, EN, and GB standards.

• Inspection Processes: Raw material inspection → In-process dimensional detection → Mechanical property testing → Corrosion resistance testing → Non-destructive testing (UT, ET, MT) → Final surface inspection.

• Quality Commitment: Strict quality control throughout the production process, providing complete inspection reports and material certificates (MTC) for each batch of products.

Send Inquiry to This Supplier

You May Also Like

-

Anti-oxidation Wear Resistant Tubes, S31603 & 316LN Ferritic Stainless Steel Heat Exchanger TubesNegotiableMOQ: 1 Kilogram

-

High-temperature Resistant Dimensional Tubes, 1.4404 & S31653 Austenitic Stainless Steel Seamless Steel TubesNegotiableMOQ: 1 Kilogram

-

Corrosion Proof High-pressure Tubes, 1.4406 & 316Ti Ferritic Stainless Steel Superheater TubesNegotiableMOQ: 1 Kilogram

-

Smooth Inner Wall Heat Resistant Tubes, S31635 & 1.4571 Austenitic Stainless Steel Boiler TubesNegotiableMOQ: 1 Kilogram

-

Precision Dimensional Anti-fatigue Tubes, 316LMoD & 316LUG Ferritic Stainless Steel Heat Exchanger Tubes for High-temperature ApplicationsNegotiableMOQ: 1 Kilogram

-

High-pressure Tolerant Corrosion Tubes, 1.4435 & 317L Austenitic Stainless Steel Seamless Stainless Steel TubesNegotiableMOQ: 1 Kilogram

-

Temperature Resistant Wear Proof Tubes, S31703 & 1.4438 Ferritic Stainless Steel Superheater TubesNegotiableMOQ: 1 Kilogram

-

Anti-corrosion High-strength Tubes, 310S & S31008 Austenitic Stainless Steel Boiler TubesNegotiableMOQ: 1 Kilogram

-

Heat Resistant Smooth Surface Tubes, 1.4845 & 314 Ferritic Stainless Steel Steel Tubes for High-temperature ServiceNegotiableMOQ: 1 Kilogram

-

Pressure Applicable Precision Tubes, 1.4841 & 310MoLN Austenitic Stainless Steel Heat Exchanger TubesNegotiableMOQ: 1 Kilogram