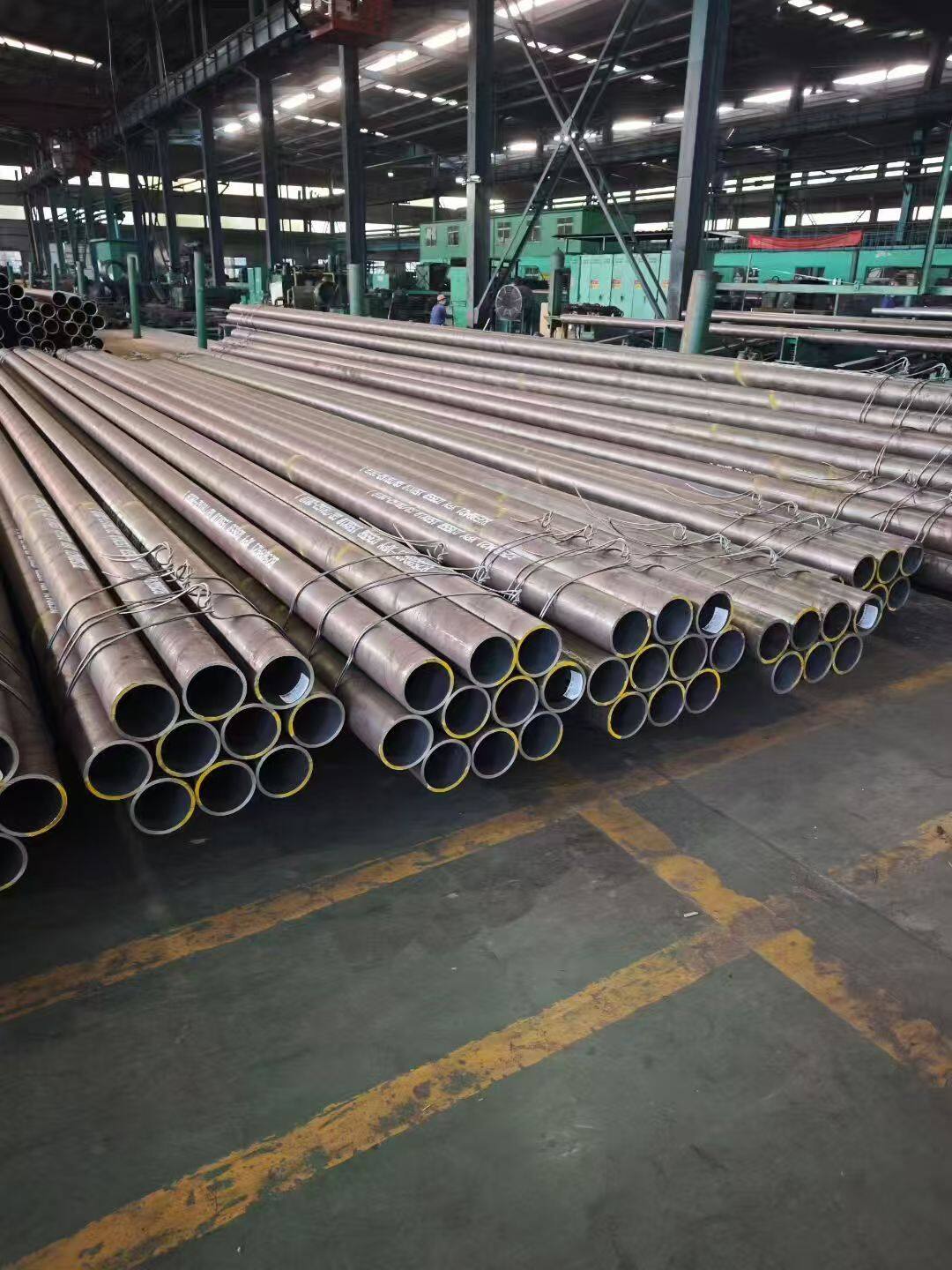

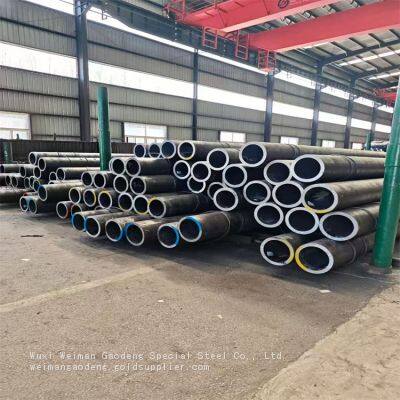

Water Wall Tube A335 P9 Seamless Pipe High Temperature Resistant Corrosion Proof Boiler Systems

Alloy Steel Pipes & Seamless Tubes Product DetailsCore Selling Points

• Multi-material coverage: Complies with ASTM and EN standards, including A213 T5/P5, T9/P9, T11/P11, T12/P12, T22/P22, T91/P91, T92/P92, 1.7362, 1.7386, 1.4903, 1.4901, 1.4922, X20CrMoV11-1.

• High-performance adaptation: Resistant to high temperature, corrosion, and pressure; wear-resistant with stable structural strength for extreme working conditions.

• Precision manufacturing: Strict dimensional tolerance control, seamless forming process, and consistent product quality for industrial reliability.

Material SpecificationsASTM Standard Materials

• A213 Series: T5, T9, T11, T12, T22, T91, T92 (seamless tubes for boilers and heat exchangers)

• A335 Series: P5, P9, P11, P12, P22, P91, P92 (alloy steel pipes for high-temperature and high-pressure service)

EN Standard Materials

• 1.7362, 1.7386, 1.4903, 1.4901, 1.4922, X20CrMoV11-1 (European standard alloy steel tubes for industrial thermal equipment)

Product Range & Applications

Product Type | Typical Applications |

Boiler Pipe | Industrial boilers, power plant boilers, thermal power generation systems |

Heat Exchanger Pipe | Chemical industry heat exchangers, refrigeration equipment, thermal transfer systems |

Water Wall Tube | Boiler water wall systems, high-temperature furnace heating surfaces |

Superheater Pipe | Power plant superheaters, reheaters, high-temperature steam pipelines |

High Temperature Seamless Pipe | High-temperature industrial pipelines, petrochemical cracking units |

Alloy Steel Pipe/Tube | Industrial piping systems, pressure vessels, heavy machinery components |

Product Advantages

1. Performance Stability: Formulated with high-quality alloy elements, the products maintain mechanical properties at temperatures up to 650℃, with excellent oxidation and creep resistance.

2. Precision Craftsmanship: Adopts hot rolling + cold drawing process, with dimensional accuracy up to ±0.05mm, ensuring tight fitting with equipment components.

3. Corrosion Resistance: The alloy composition effectively resists corrosion from steam, chemical media, and acidic/alkaline environments, extending service life.

4. Wide Compatibility: Suitable for power generation, petrochemical, chemical, metallurgical, and other industries, matching various thermal equipment requirements.

Technical Parameters

• Operating Temperature Range: -20℃ to 650℃

• Pressure Bearing Capacity: Up to 35MPa (depending on material and specification)

• Size Range: Outer diameter 10mm-1016mm, wall thickness 1mm-200mm (customizable)

• Execution Standards: ASTM A213, ASTM A335, EN 10216-2, DIN 17175

• Surface Treatment: Annealed, pickled, passivated, or as per customer requirements

Order Information

• Customization: Accepts non-standard size, material combination, and surface treatment customization.

• Quality Assurance: 100% raw material inspection, dimensional testing, and performance verification before delivery; provides material certification (MTC).

• Delivery Cycle: 7-20 working days (varies by order quantity and specification).

Send Inquiry to This Supplier

You May Also Like

-

Boiler Tube A213 T91 Seamless Steel Pipe Corrosion Resistant Wear Resistant Superheater SystemsNegotiableMOQ: 1 Ton

-

Alloy Steel Pipe A335 P91 High Temperature Seamless Pipe High Strength Pressure Bearing Industrial BoilersNegotiableMOQ: 1 Ton

-

Water Wall Tube A213 T92 Seamless Tube High Temperature Resistant Corrosion Proof Power PlantsNegotiableMOQ: 1 Ton

-

Superheater Tube A335 P92 Alloy Pipe Pressure Resistant Precision Dimension Industrial Heating SystemsNegotiableMOQ: 1 Ton

-

Seamless Steel Tube 1.7362 Alloy Steel Pipe Corrosion Resistant High Pressure Bearing Heat ExchangersNegotiableMOQ: 1 Ton

-

High Temperature Seamless Pipe 1.7386 Seamless Pipe Wear Resistant High Temperature Bearing Boiler PipingNegotiableMOQ: 1 Ton

-

Heat Exchanger Pipe 1.4903 Alloy Tube Precision Dimension Corrosion Resistant Chemical IndustryNegotiableMOQ: 1 Ton

-

Boiler Pipe 1.4901 Seamless Steel Pipe High Temperature Resistant High Strength Industrial ApplicationsNegotiableMOQ: 1 Ton

-

Alloy Pipe 1.4922 Seamless Tube Corrosion Resistant Pressure Resistant Power Plant BoilersNegotiableMOQ: 1 Ton

-

Water Wall Tube X20CrMoV11-1 Alloy Steel Pipe High Temperature Resistant Wear Resistant Industrial SystemsNegotiableMOQ: 1 Ton