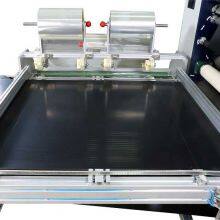

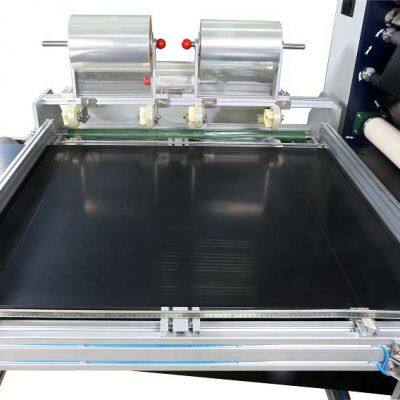

DELISH Semi Automatic Thermal Transfer Ribbon Slitter RSDS2 PLUS

High-speed slitting for efficient production

Laser or rotary blade cutting systems for clean, precise cuts

Automatic tension control to prevent ribbon deformation

User-friendly interface for easy operation and adjustment

Compatibility with wax, wax-resin, and resin-based ribbons

| Jumbo roll width | 650mm~1010mm | Controlsystem(RSDS1 PLUS) | INOVANCE PLC & touch panel |

| Jumbo roll diametermax | 630mm | Drive systemy(RSDS1 PLUS) | INOVANCE servo motors |

| Jumbo roll core dia | 6 inch/3 inch | Controlsystem(RSDS2 PLUS) | SIEMENS PLC & touch panel |

| Max.speed | 300m/min | Drive system(RSDS2 PLUS) | SANYO servo motors |

| Film thickness | 4~20um | Power | AC380V/220V,50~60Hz |

| Finished roll core | 1 inch / 1/2inch | Motor power | 6KW |

| Finished roll dia | 120mm | Air power | 0.6~0.8MPa |

| L,Tapplication table | Semi-auto leader table with ribbon saving setting | Dimension | 2400*2240*1660(mm) |

| Blade holder qty | 25pcs |

A thermal transfer ribbon slitter is a precision machine used to cut large rolls of thermal transfer ribbon into narrower widths according to specific customer requirements. This equipment ensures high accuracy, smooth edges, and consistent tension control, making it essential for producing customized ribbons used in barcode printing, labeling, and other thermal transfer applications.

Where excellence meets trust-partner with us for sustainable growth!

Delish' s senior R&D team is made up of first-class elites from the industry that have abundant experience in product design and performance control. We have many patents and seek for ever greater perfection throughout the process including R&D, production, measurement and control to ensure that the products are smarter, safer and more efficient.

Delish insists on"Change to meet changes".Driven by customers'actual demand,our core R&D team specializes in auto equipment drawing design,program composition.custom development of electrical equipment, independent production at high-end CNC machining center, precision assembly and debugging,and strict process management in order to ensure that all functions pass the test and that the equipment is suitable for continuous,stable production toachieve customer value maximization.

Delish provides intelligent factory upgrade solutions to meet customer demand,and builds an effective connection with customers'operational systems including ERP for intelligent operational task assignment to realize auto and intelligent production to help the customers improve their operational eficiency.

Delish adopts international famous-brand components and conducts balance control during machine installation in accordance with high-precision requirements to ensure the stability of tension for product slitting at high speed.

Our professional marketing service team offerall-round pre-sale,in-sale,and after-sale services.Our 24-hour response system ensures that we provide a timely analysis and solution for customers.

Send Inquiry to This Supplier

You May Also Like

-

DELISH Barcode Ribbon Slitting MachineUS$ 20000 - 60000MOQ: 1 Piece

-

DELISH High Speed Slitting MachineUS$ 20000 - 60000MOQ: 1 Piece

-

DELISH Film Slitting MachineUS$ 20000 - 60000MOQ: 1 Piece

-

DELISH Ribbon Slitting MachineUS$ 20000 - 60000MOQ: 1 Piece

-

DELISH Cold Foil SlitterUS$ 20000 - 60000MOQ: 1 Piece

-

DELISH Gold Foil SlitterUS$ 20000 - 60000MOQ: 1 Piece

-

DELISH Mini Slitter 450SUS$ 5000 - 10000MOQ: 1 Piece

-

DELISH Mini Slitter 450US$ 5000 - 10000MOQ: 1 Piece

-

DELISH Mini Slitter 300SUS$ 5000 - 10000MOQ: 1 Piece

-

DELISH Mini Slitter 350MMUS$ 5000 - 10000MOQ: 1 Piece