Material

EPDM

Usage

Other, River damming

Transport Package

Container

Specification

Custom-made according to the drawings

Trademark

HaoGu

Origin

China

Pneumatic Shield Dam: A Modern Solution for Water Retention & Flood Control

The pneumatic shield dam (also known as an air-shield dam) is an innovative flexible water-retaining structure that integrates the advantages of rubber dams (flexibility) and rigid dams (stability). It uses compressed air to inflate a rubber (airbag) and drive rigid steel shields to form a water barrier, enabling efficient water level regulation while overcoming the limitations of traditional dam types (e.g., poor impact resistance of rubber dams, high cost of concrete dams). Below is a detailed overview of its structure, working principle, advantages, and applications.

1. Core Structure

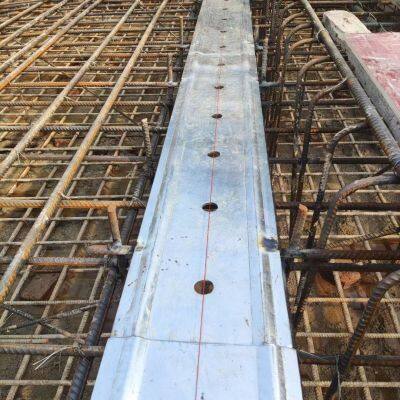

A pneumatic shield dam consists of three key components, designed for durability, safety, and easy operation:

Airbag (Inflatable Core): Made of high-strength reinforced rubber (e.g., EPDM or neoprene), with multiple layers of fiber fabric (nylon or polyester) for anti-tearing and pressure resistance. It serves as the "power source" to lift the steel shields, with a design pressure of 0.15–0.3 MPa to withstand upstream water pressure.

Steel Shield Panels: Modular rigid panels (usually Q235 or stainless steel) installed vertically on the airbag. They form the main water-retaining surface, with a thickness of 8–12 mm (adjusted by project scale) to resist water impact and floating debris (e.g., logs, ice). Panels are connected via waterproof gaskets to prevent leakage.

Inflation/Deflation System: Includes an air compressor, pressure sensor, control valve, and pipeline network. It automatically adjusts air pressure in the airbag based on water levels—ensuring stable shield lifting and enabling rapid deflation for flood discharge. A manual backup system is also equipped for emergency use.

2. Working Principle

2. Working Principle

The operation of a pneumatic shield dam relies on the "inflation-lifting" and "deflation-lowering" cycle of the airbag, with simple yet reliable logic:

Water Retention (Inflation Mode): When water storage or level regulation is needed, the air compressor injects compressed air into the airbag. As the airbag expands, it pushes the steel shields upward along guide rails until they form a continuous vertical barrier. The shields block upstream water, and the airbag’s internal pressure balances the water pressure to maintain stability.

Flood Discharge (Deflation Mode): During heavy rains or floods, the control system opens deflation valves to release air from the airbag. The airbag deflates, and the steel shields lower under gravity (and downstream water pressure) to lie flush with the riverbed—restoring the natural channel and maximizing flood discharge capacity.

Precise Regulation: By adjusting the airbag’s pressure, the dam’s height can be fine-tuned (e.g., partial lifting) to maintain a minimum downstream flow for ecological needs (e.g., protecting aquatic habitats) or irrigation.

3. Key Advantages Over Traditional Dams

Pneumatic shield dams outperform conventional dam types in multiple aspects, making them ideal for modern water conservancy projects:

Superior Impact Resistance: The rigid steel shields resist damage from high-velocity water (up to 3–5 m/s) and floating debris—solving the problem of rubber dams being easily torn or punctured.

Rapid Response to Floods: Full deflation (and shield lowering) takes only 5–15 minutes (depending on dam length), much faster than rubber dams (30–60 minutes for deflation) or concrete dams (which cannot be lowered). This minimizes upstream flooding risks.

Low Maintenance Cost: The airbag is protected by steel shields, reducing exposure to UV radiation, sediment abrasion, and biological corrosion. Annual maintenance mainly involves checking airtightness and cleaning shields—costing 40–60% less than rubber dams.

Long Service Life: The steel shields (with anti-corrosion coating, e.g., hot-dip galvanization) and high-quality rubber airbag have a design lifespan of 25–30 years, longer than rubber dams (15–20 years) and comparable to small concrete dams.

Flexible Adaptability: Modular shields allow customization for rivers of different widths (from 10 m to 100+ m) and terrains (e.g., uneven riverbeds). It can also be integrated with ecological features (e.g., fish passages) to protect aquatic ecosystems.

4. Typical Applications

Pneumatic shield dams are widely used in water conservancy, municipal, and ecological projects due to their versatility:

River Regulation: Installed in natural rivers to stabilize water levels, prevent riverbed erosion, and maintain ecological flow—critical for river restoration projects (e.g., urban black-odor river treatment).

Flood Control: Deployed in urban or rural flood-prone areas (e.g., downstream of small reservoirs) to form temporary flood barriers. Rapid deflation ensures timely discharge during emergencies.

Landscape & Municipal Water Bodies: Used in man-made lakes, wetland parks, or waterfront areas to control water levels—maintaining an aesthetic water surface for recreation (boating, fishing) while enhancing urban hydrophilic spaces.

Irrigation & Water Supply: Applied in irrigation canals or small reservoirs to store water during dry seasons, ensuring sufficient water for farmland (especially in arid or semi-arid regions).

Hydropower Auxiliary: Used as auxiliary structures in small hydropower stations to adjust upstream water levels, increasing the water head (height difference) and improving power generation efficiency.

5. Installation & Operation Tips

Installation: The dam requires a simple concrete foundation (lower cost than concrete dams) and modular assembly—shortening construction time to 1–3 months (for a 50-m dam), 50% faster than traditional rigid dams.

Operation: Equipped with an intelligent control system (PLC + remote monitoring), it can realize unattended operation. Operators can adjust the dam height via a mobile app or control room, reducing labor demands.

Environmental Protection: The rubber airbag uses non-toxic, biodegradable materials, and the dam’s low carbon footprint (no large-scale excavation) aligns with green engineering standards.

In summary, the pneumatic shield dam combines flexibility, durability, and efficiency—making it a cost-effective and eco-friendly choice for modern water resource management. Its ability to balance flood control, water storage, and ecological protection has made it increasingly popular in projects across Asia, Europe, and North America.