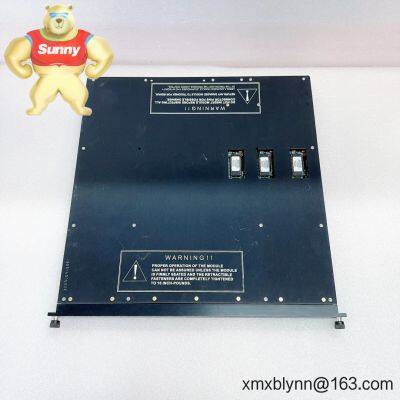

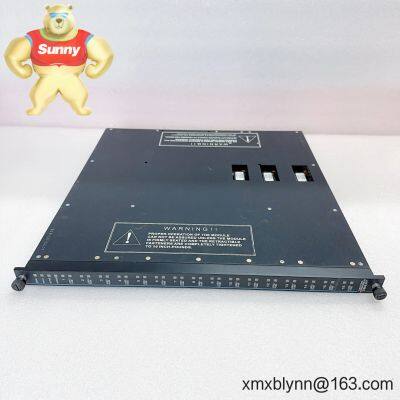

TRICONEX 3623 – TMR 24 VDC Discrete Output Module for Safety-Critical Shutdown Control

| Brand / Model | TRICONEX 3623 |

| Module Type | TMR discrete output module, 24 VDC |

| Signal Output Type | 24 VDC digital (sourcing solid-state drivers, used for solenoids/relays/indicators) |

| Safety Architecture | Triple Modular Redundancy (A/B/C legs) with 2oo3 voting and diagnostics |

| Backplane / Power | Powered via Tricon backplane (no external power to the card itself) |

| Operating Temperature | Typically 0 to +60°C when installed in a standard Tricon chassis |

| Communication Interface | Tricon system backplane; plant/host comms handled by Tricon communication modules |

| Installation Method | Plug-in I/O card; field wiring terminates at external termination assemblies (ETAs) |

Emergency Shutdown (ESD) and High-Integrity Protective Functions in oil & gas and petrochem.

Fire & Gas systems that need deterministic control of beacons, sounders, and deluge solenoids.

Boiler/BMS and burner management where proof-testing and online diagnostics save turnaround time.

Turbomachinery and compressor protection where fast, clean 24 VDC actuation is essential.

Power generation balance-of-plant interlocks and process shutdown sequences.

High availability – TMR design maintains control through single faults and aids rapid root cause isolation.

Lifecycle-friendly – Hot-repair support and modular field terminations reduce outage duration and spares exposure.

Proven compatibility – Works within the Tricon ecosystem alongside existing processors and communication modules.

Cost control – In many cases, the 3623 lets you keep 24 VDC at the field, minimizing interposing hardware and wiring complexity.

Safety performance – SIL3 capability when applied per IEC 61508 simplifies functional safety justifications.

“We swapped a 3623 during a unit start-up window. No process trip, diagnostics pointed straight to a wiring fault on one leg. It saved us a day of hunting.” — Maintenance Lead, downstream user

Panel environment – Install in a Tricon chassis inside a well-ventilated cabinet; maintain clear airflow and stable 24 VDC supply quality.

Wiring practices – Segregate safety I/O from noisy power runs, use ferrules, label rigorously; add flyback diodes for inductive loads unless handled by the ETA.

Load ratings – Match output current and inrush limits; for higher loads, drive interposing relays rated for the duty.

Proof testing – Periodically function-test outputs and final elements per the safety plan; capture timestamps in your SIS maintenance records.

Hot-repair – Replace modules using the manufacturer’s online maintenance procedure; verify leg health and output permissives before returning to service.

Firmware/config management – Keep a controlled baseline of system firmware and configuration; update only under MOC with rollback plans.

IEC 61508 SIL3 certification when used in a TRICONEX system and applied per the safety manual.

CE compliance for EMC and low-voltage directives (typical for Tricon modules).

UL/CSA industrial control equipment listings in many configurations.

RoHS-conscious design where applicable.

Manufacturer warranty: typically 1 year; extended service agreements available through lifecycle support programs.

TRICONEX 4351B Tricon Communication Module (TCM) – Handles peer-to-peer and host connectivity for the Tricon system, letting you keep the 3623 focused on deterministic I/O.

TRICONEX 3503E Main Processor (MP) – High-availability CPU module executing the safety logic and coordinating I/O voting across A/B/C legs.

External Termination Assemblies (ETAs) for 24 VDC DO – Field wiring interface boards matched to the 3623; choose versions with integral fusing or surge suppression depending on load type.

Interposing relay boards – Recommended where loads exceed the electronic output’s rating or require galvanic isolation from field power.

You might notice the 3623 shows up wherever quick, clean 24 VDC actuation matters: tripping a compressor antisurge valve, energizing a deluge skid solenoid, or driving a bank of safety beacons through interposing relays. In many cases, plants standardize on this card to simplify spares and keep maintenance procedures consistent across units.

Send Inquiry to This Supplier

You May Also Like

-

TRICONEX 3005 – TMR Safety System Module for Critical Process ProtectionUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 3004 – Compact 4‑Slot Chassis for Tricon TMR Safety SystemsUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 3003 – Main Processor Module for Tricon TMR Safety SystemsUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 2700 – TMR Safety System Hardware for High‑Integrity ControlUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 2755 – Safety-Critical Digital Input Module for Tricon TMR SystemsUS$ 2360.00MOQ: 1 Combo

-

TRICONEX 3002 – Compact Tricon TMR Chassis/Backplane for Safety System ExpansionUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 2652 – TMR I/O Module for High-Integrity Safety and Shutdown DutiesUS$ 860.00MOQ: 1 Combo

-

TRICONEX 2481 – TMR System Module for High-integrity Safety ControlUS$ 4360.00MOQ: 1 Combo

-

TRICONEX EM2292 – Electronic Module for Triconex Safety Controller ExpansionUS$ 460.00MOQ: 1 Combo

-

TRICONEX 2351 – TMR Safety System Module for Critical Control and ShutdownUS$ 4360.00MOQ: 1 Combo