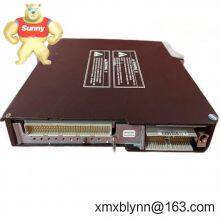

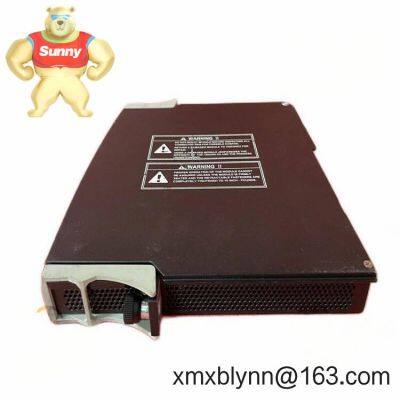

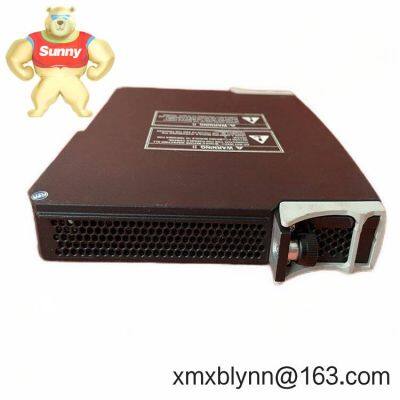

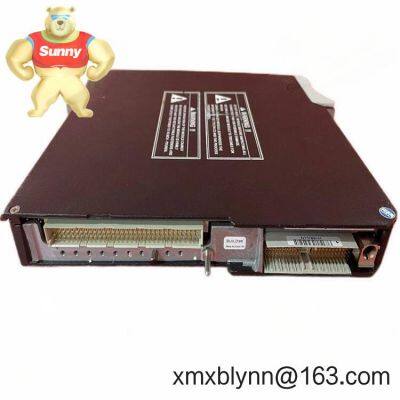

TRICONEX 3510 – Triple‑Modular‑Redundant System Module for SIL3 Safety Control

| Brand / Model | TRICONEX 3510 |

| System Role | TMR system module for Tricon safety controller platforms (SIL3-capable architecture) |

| Power Requirements | Backplane powered; the Tricon system typically uses redundant 24 VDC supply modules at the cabinet level |

| Dimensions & Weight | Standard 3500‑series plug‑in card; fits Tricon chassis (module position A/B/C per TMR leg) |

| Operating Temperature | Typically control‑room range (e.g., 0 to 60°C); follow system manual and cabinet derating guidance |

| Signal I/O Types | Functions through the Tricon backplane; field I/O handled by separate DI/DO/AI/AO modules and termination panels |

| Communication Interfaces | Redundant Tricon backplane; plant/host connectivity typically via optional communications modules (e.g., Ethernet gateways) |

| Installation Method | Plug‑in card; mounted in the appropriate TMR slot positions with matching modules across three legs |

| Safety Level | Designed for use in IEC 61508 SIL3 applications when used as part of a certified Tricon system |

Plants typically deploy the TRICONEX 3510 in safety instrumented systems where shutdown logic and protective interlocks must remain online during maintenance. It’s well‑suited for:

Emergency Shutdown (ESD) and High Integrity Pressure Protection Systems (HIPPS)

Burner Management Systems (BMS) and boiler protection

Gas compression, turbine and generator protection, overspeed, and auxiliary safeties

Petrochemical unit safeguarding, offloading terminals, and tank farm protection

Power plants and critical utilities where high availability is expected

Reliability that reduces nuisance trips – TMR design with voting logic seems to be the preferred choice in plants that can’t afford spurious shutdowns.

Compatibility and migration – Works within the established Tricon ecosystem; in many cases you can add/upgrade modules while keeping field terminations intact.

Lower lifecycle cost – Hot‑swappable maintenance and strong diagnostics help cut planned downtime and technician hours.

Support and documentation – Widely deployed worldwide, so procedures, best practices, and trained engineers are easier to find.

One thing I appreciate is how predictable the upgrade path is—sites often standardize spares across multiple units. A maintenance lead at a gas processing plant told us they swapped a failed leg during operation, validated status in minutes, and avoided delaying a ship‑loading window.

Installation & MaintenanceCabinet & environment – Install in a clean, dry control cabinet with adequate ventilation; follow spacing and ambient limits for the Tricon chassis.

Wiring & grounding – Bond cabinet ground properly; keep I/O, power, and network cabling segregated; observe shield termination practices on termination panels.

Slotting consistency – Match module type and revision across the three TMR legs (A/B/C). Verify firmware compatibility before insertion.

Hot‑swap handling – Use ESD precautions, pull/insert straight, and confirm status indicators and system diagnostics before returning the loop to service.

Routine care – Periodic visual inspections, dust removal with dry air, configuration backups, and scheduled proof‑testing aligned to your SIF validation plan.

Firmware & records – Keep a controlled firmware baseline; document module serials and revisions for compliance and faster troubleshooting.

IEC 61508 SIL3 certified for use within the Tricon safety system (TÜV assessed)

CE compliant; typical listings include UL/CSA for industrial control equipment

Manufactured under ISO 9001 quality systems

RoHS alignment for materials where applicable

Manufacturer’s standard warranty (commonly 12 months); extended service options available in many regions

If you’re matching an existing install, share your chassis type and firmware baseline; we can help confirm the TRICONEX 3510 revision that aligns with your site standard without surprises.

Send Inquiry to This Supplier

You May Also Like

-

TRICONEX 2700 – TMR Safety System Hardware for High‑Integrity ControlUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 2755 – Safety-Critical Digital Input Module for Tricon TMR SystemsUS$ 2360.00MOQ: 1 Combo

-

TRICONEX 3002 – Compact Tricon TMR Chassis/Backplane for Safety System ExpansionUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 2652 – TMR I/O Module for High-Integrity Safety and Shutdown DutiesUS$ 860.00MOQ: 1 Combo

-

TRICONEX 2481 – TMR System Module for High-integrity Safety ControlUS$ 4360.00MOQ: 1 Combo

-

TRICONEX EM2292 – Electronic Module for Triconex Safety Controller ExpansionUS$ 460.00MOQ: 1 Combo

-

TRICONEX 2351 – TMR Safety System Module for Critical Control and ShutdownUS$ 4360.00MOQ: 1 Combo

-

TRICONEX 2301 – Triple-Redundant Module for High-Integrity Tricon SIS ApplicationsUS$ 4360.00MOQ: 1 Combo

-

TRICONEX EM2291 – Expansion/Interface Module for Tricon TMR Safety SystemsUS$ 860.00MOQ: 1 Combo

-

TRICONEX EM2281 – Expansion/Interface Module for Tricon Safety SystemsUS$ 560.00MOQ: 1 Combo