Titanium Rod TA2/TA3 Factory Direct for Chemical and Food Processing, Non-Toxic Material

Introduction

In the realm of chemical and food processing industries, the choice of materials is of utmost importance. Our Titanium Rod TA2/TA3, offered directly from the factory, stands out as an exceptional solution. Titanium is well - known for its outstanding properties, and our rods are specifically crafted to meet the rigorous demands of these industries.

Product Overview

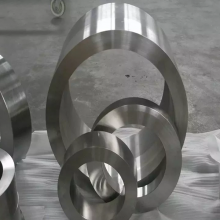

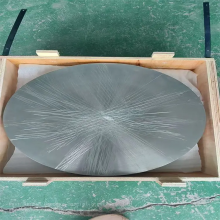

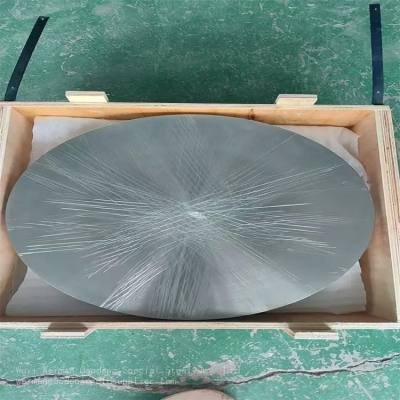

- Material Composition: These rods are made from Titanium TA2/TA3. Titanium is a remarkable metal with a high strength - to - weight ratio, excellent corrosion resistance, and biocompatibility. TA2 and TA3 grades are particularly well - suited for applications where non - toxicity and high chemical stability are required.

- Surface Treatment: The rods feature a bright rod surface treatment. This not only gives them an aesthetically pleasing appearance but also helps in maintaining the cleanliness and smoothness of the surface. A smooth surface is crucial in chemical and food processing to prevent the accumulation of contaminants.

- Shape and Color: They come in a bar shape, which is a common and versatile form. The silver color is characteristic of titanium, adding to its modern and industrial look. The bar shape allows for easy machining and customization according to specific application requirements.

Key Features

- Non - Toxicity: One of the most significant advantages of our Titanium Rod TA2/TA3 is its non - toxic nature. In food processing, this is a critical requirement as any contact between the material and food products must not introduce harmful substances. Similarly, in the chemical industry, non - toxicity ensures the safety of the chemical processes and the end - products.

- Corrosion Resistance: Titanium is highly resistant to corrosion, making these rods ideal for use in chemical environments where they may come into contact with various corrosive substances. Whether it's acids, alkalis, or salts, the rods can withstand the corrosive effects, ensuring a long service life and reducing the need for frequent replacements.

- High Strength: Despite its relatively low density, titanium has high strength. This means that the rods can withstand significant mechanical stress without deforming or breaking. In chemical and food processing equipment, where there may be pressure, vibration, or other mechanical forces, the high - strength property of these rods is invaluable.

Applications

- Chemical Processing: In the chemical industry, these rods can be used in a variety of equipment such as reactors, heat exchangers, and piping systems. Their corrosion resistance allows them to handle different chemical substances, and their non - toxicity ensures that they do not contaminate the chemical processes. For example, in a chemical reactor where aggressive chemicals are being mixed and reacted, the Titanium Rod TA2/TA3 can be used as structural components or as part of the stirring mechanism.

- Food Processing: In the food processing industry, these rods are suitable for use in equipment like food handling conveyors, mixing machines, and storage containers. Their non - toxic nature makes them compliant with food safety regulations, and their corrosion resistance ensures that they can withstand the cleaning agents and food acids used in the processing environment. For instance, in a dairy processing plant, the rods can be used in the construction of milk storage tanks.

Manufacturing and Quality Assurance

- Factory Direct: As a manufacturer, we offer these rods directly from the factory. This eliminates the middle - man and allows us to provide high - quality products at competitive prices. We have full control over the manufacturing process, from the selection of raw materials to the final finishing of the rods.

- Quality Standards: Our manufacturing process adheres to international standards such as ASTM, EN, and JIS. We have a team of expert metallurgists and quality control inspectors who ensure that each rod meets the strictest quality criteria. Our advanced NDT (Non - Destructive Testing) services, including Ultrasonic Testing (UT) to EN 10228 - 3 and Magnetic Particle Testing (MT), help us detect any internal or surface defects, ensuring that only the best - quality rods are delivered to our customers.

Company Background

Our company, established in 2017, has a rich history of innovation and growth in the special steel industry. We started with a focus on R & D for power plant boiler steel and have since expanded our product range to include various alloys, including titanium. We have a team of experienced professionals, including a CEO with over 20 years of experience in the special steel industry and a chief metallurgist with a PhD from Tsinghua University. Our company has also established global partnerships with well - known companies, ensuring that we have access to the latest technology and premium raw materials. With an annual export share of US$5 Million - US$10 Million, we serve customers in multiple regions around the world, including North America, South America, Europe, Asia, and Africa.

In conclusion, our Titanium Rod TA2/TA3 is a top - quality product that offers excellent performance, safety, and reliability for chemical and food processing applications. With our factory - direct approach and commitment to quality, we are confident that we can meet the diverse needs of our international customers.

Send Inquiry to This Supplier

You May Also Like

-

TC6/GR12 Titanium Alloy Rod for Engineering and Manufacturing, High-Performance MaterialNegotiableMOQ: 100 Kilograms

-

GR5/TA2 Titanium Alloy Bar for Automotive and Aerospace Industries, Factory PriceNegotiableMOQ: 100 Kilograms

-

Factory Direct GR5 Titanium Alloy Bar Ti-6Al-4V ASTM B348 for Aerospace & Aircraft Engine Parts Bulk SupplyNegotiableMOQ: 100 Kilograms

-

ASTM F136 Medical Grade Titanium Rod GR23 (TC4 ELI) FDA Certified for Orthopedic & Dental ImplantsNegotiableMOQ: 100 Kilograms

-

Bulk GR2 Pure Titanium Round Bar TA2 ASTM B348 Pickled Finish for Chemical & Desalination ProjectsNegotiableMOQ: 100 Kilograms

-

Custom Size Ti6Al4V Titanium Bar GR5 With H6-H9 Tolerance for Precision Semiconductor EquipmentNegotiableMOQ: 100 Kilograms

-

ASME SB-348 Grade 12 Titanium Rod Heat-Resistant for Nuclear Reactors & Geothermal SystemsNegotiableMOQ: 100 Kilograms

-

Corrosion-Resistant GR7 Titanium Bar (Ti-0.15Pd) ASTM B348 for Chlorine Handling EquipmentNegotiableMOQ: 100 Kilograms

-

Polished GR5 Titanium Hexagonal Bar for Luxury Watch Cases & High-End Consumer ElectronicsNegotiableMOQ: 100 Kilograms

-

Forged Titanium Alloy Bar GR9 (Ti-3Al-2.5V) AMS 4928 for Aerospace Tubing ApplicationsNegotiableMOQ: 100 Kilograms