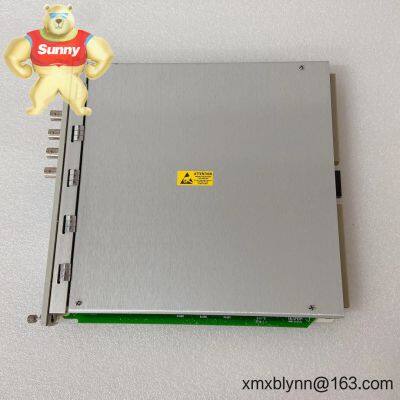

Bently Nevada 3500/40-01-00 Proximitor Monitor – 4‑Channel Vibration/Position Monitoring for Critical Rotating Assets

The Bently Nevada 3500/40-01-00 is a 4‑channel Proximitor Monitor designed for proximity probe measurements such as radial vibration, shaft position, and eccentricity in turbines, compressors, pumps, and other high‑value rotating machines. It integrates into the 3500 rack for continuous condition monitoring and configurable protection logic, typically tied into plant trip systems via rack relays.

One thing I appreciate is how it keeps the setup straightforward: proximity inputs in the back I/O, meaningful vibration/position variables in the front end, and seamless data flow to the rack controller (TDI) for System 1 software. In many cases, it’s the go‑to module when you need dependable, gap‑free measurements from 3300 XL or compatible proximity transducer systems.

Key FeaturesFour independent proximity channels – Each channel can be configured for radial vibration, shaft position, or eccentricity, giving you flexibility across machine trains.

Seamless rack integration – Works within the Bently Nevada 3500 system; data is shared via the backplane to the TDI (3500/22M) for Ethernet and System 1 connectivity.

Continuous protection – Supports alarm setpoints and logic for real‑time protection; typical applications tie into rack relay modules for machine trip or shutdown.

Proximity transducer compatibility – Designed to work with Bently Nevada 3300 XL and similar proximitor systems, which simplifies spares and maintenance across sites.

Configurable measurement processing – From my experience, users typically enable 1X tracking (with a Keyphasor module present), gap, and overall vibration for clear diagnostic insight.

Back‑mounted I/O module – Clean wiring to field proximitor drivers; the front card stays serviceable without disturbing field terminations.

Ordering code 3500/40‑01‑00 – Commonly interpreted as the standard proximitor monitoring option with no 4–20 mA recorder outputs; consult your configuration to confirm.

| Brand / Model | Bently Nevada 3500/40-01-00 (Proximitor Monitor) |

| Channels | 4 proximity probe channels (independent) |

| Power Requirements | Supplied via 3500 rack backplane (no external power on the module) |

| Form Factor | Two‑slot monitor: front module + matching back I/O module |

| Operating Temperature | Typically 0 to +65 °C (rack ambient); verify with the official datasheet for your build |

| Signal Inputs | Proximity transducer systems (e.g., Bently Nevada 3300 XL); measures radial vibration, shaft position, eccentricity |

| Recorder Outputs | Option-dependent; the -01-00 variant is commonly specified without 4–20 mA recorder outputs |

| Communication | Via 3500 rack backplane to TDI (3500/22M) for Ethernet / System 1 connectivity |

| Installation | Mounts in 3500 rack; field wiring lands on rear I/O module terminals |

This module is typically specified for continuous protection and condition monitoring of:

Steam and gas turbines – radial vibration, thrust/bearing position, and runout checks with a Keyphasor present.

Compressors and expanders – stable proximity measurements for surge‑critical equipment.

Pumps, fans, blowers – reliable overall vibration trending for predictive maintenance.

Refining, petrochemical, pipeline, power generation, paper, and steel plants – especially where System 1 data is part of the workflow.

A maintenance lead at a downstream facility told me they swapped a mixed fleet of legacy monitors for 3500/40 units across pumps and a coker compressor train. “Trending got cleaner, and our nuisance trips fell off,” was his summary after a quarter of runtime.

Advantages & ValueReliability – Proven hardware in harsh environments; fewer measurement dropouts and stable long‑term trends.

Compatibility – Works with common Bently Nevada proximity systems; simplifies spares and reduces calibration complexity.

Lower lifecycle cost – Standardized 3500 rack architecture means less training overhead and faster card replacement.

Integration readiness – Ties into the TDI for Ethernet and System 1, which, in many cases, shortens commissioning and reporting cycles.

Protection confidence – Clear alarm logic and channel configuration support precise trip criteria when combined with rack relay modules.

Bently Nevada 3300 XL Proximity Transducer System – Typical probe/extension cable/Proximitor assemblies used with the 3500/40.

Bently Nevada 3500/22M TDI – Rack controller and Ethernet interface for System 1 connectivity and configuration.

Bently Nevada 3500/25 Keyphasor Module – Provides phase reference for 1X amplitude/phase and advanced vibration diagnostics.

Bently Nevada 3500/32M or 3500/33 Relay Modules – Centralized alarms/trips for protection logic driven by monitor channels.

Rack & cabinet – Install in a 3500 rack within a clean, ventilated cabinet. Maintain ambient within the specified rack temperature range.

Wiring – Land proximity probe wiring on the rear I/O module. Keep transducer cables separated from high‑voltage lines; use shielded cable and proper grounding.

Keyphasor – For 1X tracking and phase data, add a 3500/25 Keyphasor module and configure channel associations accordingly.

ESD & handling – Handle the front card and I/O with ESD precautions; insert/remove with rack power isolated when practical.

Calibration & checks – Periodically verify probe gaps and scale factors; from my experience, an annual check aligns well with turnaround schedules.

Firmware/configuration – Keep rack firmware and System 1 versions aligned per GE/Bently Nevada guidance; back up configuration files after any change.

Certifications – Typically CE and UL/cUL for industrial control equipment; many installations target Class I, Div 2 / Zone 2 environments. Verify your exact module’s approvals.

RoHS/Reach – Compliance status varies by build date and region; documentation is available per serial/part number.

Warranty – Manufacturer’s limited warranty applies per Bently Nevada policy; keeping a clear event and maintenance history helps with any claims.

If you’re standardizing on the 3500 platform or replacing mixed legacy monitors, the 3500/40-01-00 seems to be the safe choice for proximity‑based measurements. It keeps spares simple, commissioning predictable, and protection logic consistent across units.

Send Inquiry to This Supplier

You May Also Like

-

Bently Nevada 350900HTVAS-A0-B4 Probe Connection Cable – High‑Temperature Lead for Proximity/Vibration SensingNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/42-01-01 – 4‑Channel Proximitor/Seismic Monitor for Critical Machinery ProtectionNegotiableMOQ: 1 Combo

-

Bently Nevada 330180-90-05 Proximitor Sensor – Front-end Conditioning for 3300 XL Proximity MeasurementsNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/92-IS Communications Module – Reliable Modbus Gateway for the 3500 Machinery Protection RackNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/42-I-01 Proximitor/Seismic Monitor – 4‑Channel Vibration Protection for Critical MachineryNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/65-01-01 Input Module – High-integrity Signal Acquisition for the 3500 Protection SystemNegotiableMOQ: 1 Combo

-

BENTLY 330180-91-05 Preamplifier for Proximity MonitoringNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/25-02-01 Keyphasor Module – Dual-channel Phase Reference for Precise Speed and Phase TrackingNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/33-IS-01 Relay Module – Intrinsically Safe, 16‑Channel Alarm/Trip Outputs for 3500 RacksNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/33-01-01 – Dual Speed/Acceleration Monitor for Critical Machinery ProtectionNegotiableMOQ: 1 Combo