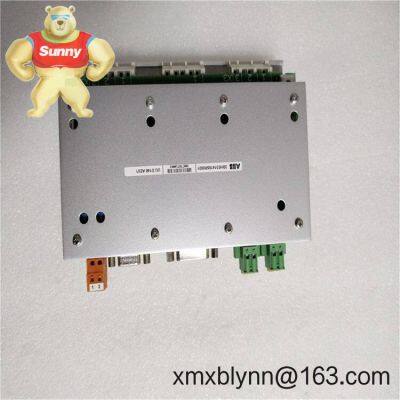

ABB UUD148AE01 (3BHE014185R0001) – High‑speed I/O Board for AC 800PEC and Power Electronics Control

Warranty period: 365 days

Delivery time: typically 1 week if in stock; no more than one month at the latest

Payment: 50% advance; full payment prior to delivery

Express delivery options: FedEx, UPS, DHL

Each unit is inspected and securely packed; ESD and moisture barrier packaging are used in most cases

AC 800PEC ecosystem fit – Designed for ABB’s high‑speed PEC architecture, typically used in power electronics control.

Fast digital I/O handling – Optimized for deterministic signal processing; suitable for interlocks, gating, or fast status capture.

Galvanic isolation – I/O channels are typically opto‑isolated to reduce ground loops and noise ingress in high‑EMI environments.

Backplane communication – Direct interface to the PEC backplane for low‑latency data exchange with the CPU board.

Serviceability – Front‑panel access, status indication, and plug‑in form factor keep swap‑out times short.

Industrial build quality – ABB board‑level design with robust components; conformal coating variants are common in many installations.

| Brand / Model | ABB UUD148AE01 (3BHE014185R0001) |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537 – industrial control parts) |

| Power Requirements | 24 VDC nominal via AC 800PEC backplane; typical consumption 6–10 W |

| Dimensions & Weight | Plug‑in board for PEC subrack; approx. 6U, 160 mm depth; ~0.4–0.6 kg |

| Operating Temperature | 0 to +55°C (installed in a ventilated cabinet); storage typically −25 to +70°C |

| Signal Input/Output Types | High‑speed digital I/O, 24 VDC logic levels, opto‑isolated; intended for fast status/control signals |

| Communication Interfaces | AC 800PEC backplane interface; field wiring via front connectors |

| Installation Method | Subrack plug‑in card; front‑panel fastening; connectors accessible from the front |

The UUD148AE01 is commonly deployed with AC 800PEC‑based systems in:

Medium‑voltage drives (e.g., PEC‑controlled ACS platforms) for synchronous/induction machines

Power converters and rectifier/inverter controls in metals, mining, and marine

Wind and renewable converter controls where fast gating and protection signals are critical

High‑power test benches and lab rigs requiring deterministic I/O timing

A maintenance lead at a steel plant told us it dropped straight into their existing PEC rack and cleared a stubborn I/O fault that had been causing nuisance trips—no application code changes were needed in their case.

Reliability – Proven ABB hardware; stable behavior in electrically noisy rooms and MV drive halls.

Compatibility – Appears to be fully compatible with AC 800PEC subracks and backplane signaling; helps extend asset life.

Cost control – A targeted board replacement often avoids an unnecessary controller upgrade.

Lead time – We aim for rapid shipment on stocked units; helpful when a line is down.

Support – Guidance on installation, basic checks, and firmware compatibility notes when applicable.

Cabinet & environment – Install in a clean, ventilated cabinet meeting IEC/UL industrial control standards; avoid condensation and conductive dust.

ESD handling – Use antistatic wrist straps and ESD mats; keep the board in shielding bags until installation.

Backplane & wiring – Power is provided via the PEC backplane; field I/O should use twisted‑pair, shielded cables where noise is present.

Grounding – Ensure functional earth is reliable; separation of power and signal grounds reduces interference.

Checks after replacement – Verify channel polarity/levels, run self‑test or diagnostics LEDs, and confirm CPU firmware recognizes the board.

Routine maintenance – Periodic connector re‑seating, dust cleaning with dry air, and visual inspection for hot spots; firmware updates only if recommended by the site standard.

Typically CE‑marked for industrial environments

UL/CSA applicability depends on system integration and cabinet certification

RoHS compliance may vary by production date; many legacy service parts are RoHS‑exempt under industrial categories

Manufacturer warranty practices vary by region; our supplied units carry a 365‑day warranty

AC 800PEC CPU/main controller boards (e.g., PPC‑series) for high‑speed control execution

PEC subrack/backplane assemblies and power distribution modules

Front terminal blocks and field wiring harnesses suited to the UUD‑series I/O

Send Inquiry to This Supplier

You May Also Like

-

ABB UNS4681V511 – Control System Module for Reliable DCS/PLC Maintenance and UpgradesUS$ 3865.00MOQ: 1 Pallet

-

ABB PPD113B03-19-150000 – OEM Control Module for ABB Industrial Drive/Excitation SystemsUS$ 12388.00MOQ: 1 Unit

-

ABB REF615C_E HCFEAEAGABC2BAA11E – Feeder Protection Relay for MV Distribution Control and IEC 61850 AutomationUS$ 2960.00MOQ: 1 Unit

-

ABB UNS0881b-PV2 PCB – Original Replacement Board for ABB DCS/Advant CabinetsUS$ 3699.00MOQ: 1 Pallet

-

GATE DRIVER PCB (GRD) HIEE401782R0001, LT C391 AE01 LTC391AE01US$ 4600.00MOQ: 1 Pallet

-

ABB SPIET800 Ethernet CIU – Compact Ethernet Communication Interface for 800xA / Symphony Plus SystemsUS$ 13666.00MOQ: 1 Unit

-

ABB S-123H 3BHB030479R0512 – Drive Control/Gate Interface Board for ABB Industrial DrivesUS$ 3556.00MOQ: 1 Pallet

-

ABB PVD164A2059 (3BHE014340R2059) – Phase/Voltage Detection and Drive Interface Board for ABB Industrial DrivesUS$ 3764.00MOQ: 1 Unit

-

ABB PPC322BE01 (HIEE300900R0001) – Processor Module for Advant DCS Nodes and Legacy System UpkeepUS$ 13891.00MOQ: 1 Pallet

-

ABB UCD224A103 (3BHE023681R0103) – Industrial Drive Control Board for ABB Drive and Power Electronics SystemsUS$ 6500.00MOQ: 1 Pallet