HG005 Rubber Dam, Rubber Water Dam Bags for River Blocking, Large Rubber Dam, Inflatable and Water-filled Rubber Dam, Rubber Sluice Gate

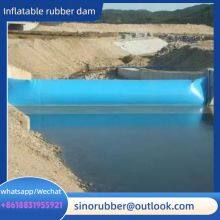

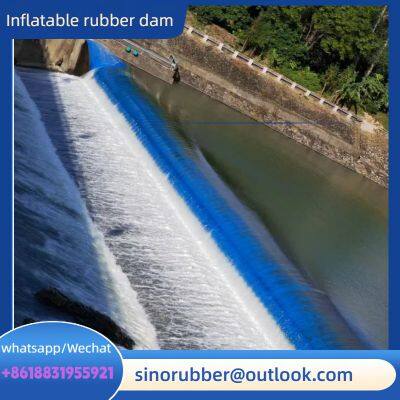

# Rubber Dams: Flexible Innovation for Modern Water Management Rubber dams, also known as flexible dams or inflatable dams, are innovative hydraulic structures composed of high-strength synthetic rubber materials. Unlike traditional rigid dams (e.g., concrete or stone dams), they rely on internal pressure (from water or air) to form a stable barrier, enabling flexible regulation of water flow, storage, and discharge. Widely applied in water conservancy, urban landscape, agricultural irrigation, and ecological restoration, rubber dams have become a core solution for efficient and eco-friendly water resource management globally.

## 1. Core Structure & Key Components A standard rubber dam system consists of four integrated parts, each optimized for durability, functionality, and easy maintenance: - **Rubber Dam Bag** The "heart" of the structure, made from high-performance elastomers such as **EPDM (Ethylene Propylene Diene Monomer)** rubber or neoprene (chloroprene rubber). Reinforced with multiple layers of polyester or nylon fabric, the dam bag resists tearing, UV radiation, chemical corrosion (e.g., sewage, industrial wastewater), and extreme temperatures (-40°C to +80°C). Its thickness (typically 3–8 mm) and size are customized to match project needs—from small irrigation dams (1–3 meters high) to large-scale hydraulic projects (up to 6.5 meters high, like the Fuyang River rubber dam in China). - **Anchoring System** A critical component that secures the dam bag to the riverbed or concrete foundations. It includes embedded steel plates, anchor bolts, and pressure strips, ensuring the dam bag stays stable even under high water pressure or rapid flow. The anchoring design prevents leakage at the dam’s edges and withstands long-term tension from the inflated dam bag. - **Inflation/Deflation System** Controls the dam’s height by adjusting internal pressure. Two common types are: - **Water-Inflated**: Uses clean water (from the river or a dedicated pipeline) to fill the dam bag—cost-effective and suitable for areas with abundant water resources. - **Air-Inflated**: Relies on compressed air (from electric or diesel air compressors)—ideal for cold regions (avoids freezing) or projects requiring fast inflation/deflation. The system also includes valves, filters, and pressure gauges for precise pressure control and leak detection. - **Control & Monitoring System** Modern rubber dams are equipped with automated or semi-automated controls. Manual systems (hand pumps, valves) suit small dams, while large projects use **IoT-enabled controllers** that integrate sensors for water level, pressure, and dam bag status. Remote monitoring allows real-time adjustments (e.g., rapid deflation during floods) and predictive maintenance, improving safety and efficiency.

## 2. Material & Performance Advantages Rubber dams outperform traditional rigid dams in multiple key aspects, making them a preferred choice for diverse scenarios: | Advantage | Description | |-----------|-------------| | **Flexible & Shock-Resistant** | The elastic rubber material absorbs impacts from floating debris or seismic activity, reducing damage risks. Unlike concrete dams, it won’t crack under minor ground shifts. | | **Cost-Effective** | Material and construction costs are 30–50% lower than concrete dams. No complex formwork or heavy machinery is needed, and installation takes just 3–15 days (vs. months for concrete dams). | | **Eco-Friendly** | When deflated ("collapsed"), the dam bag lies flat on the riverbed, allowing unobstructed water flow, fish migration, and navigation—critical for preserving aquatic ecosystems. It also avoids large-scale land occupation. | | **Space-Saving** | No massive concrete foundations are required, making it suitable for narrow rivers, urban waterways, or areas with limited construction space. | | **Low Maintenance** | The reinforced rubber material has a long service life (20–30 years with proper care). Maintenance mainly involves inspecting the dam bag for wear, cleaning filters, and replacing seals—simple and low-cost. |

## 3. Typical Applications Rubber dams are versatile and adaptable to various engineering needs, with common use cases including: - **Water Conservancy & Flood Control** Regulate river water levels, store water for dry seasons, and prevent flooding. For example, the **Xiaobudong Rubber Dam** in Linyi, China (1,135 meters long, once the world’s longest), controls the Yi River’s flow to protect downstream cities from floods. - **Urban Landscape & Ecological Restoration** Create artificial lakes, water parks, or "riverfront living rooms" to enhance urban aesthetics. The Anyang Huan River rubber dam in China, for instance, forms a 12-kilometer scenic waterway, improving air quality and public recreation space.

- **Agricultural Irrigation** Store water in canals or reservoirs to supply farmlands with stable irrigation water. Rubber dams in the Yellow River Basin (China) ensure consistent water for wheat and corn crops, boosting agricultural yields. - **Hydropower & Industrial Water Supply** Provide stable water head for small hydropower plants or supply cooling water to factories. In high-altitude regions like Tibet, air-inflated rubber dams (resistant to freezing) support local hydropower projects.

## 4. Working Principle The operation of a rubber dam is simple and efficient: 1. **Inflation (Water/Air Filling)**: When water storage or flow regulation is needed, the inflation system pumps water or air into the dam bag. As internal pressure rises, the dam bag expands upward, forming a barrier that blocks water and raises the upstream water level. 2. **Deflation (Collapse)**: During floods, droughts, or when navigation is required, the deflation system releases water/air from the dam bag. The dam bag collapses flat on the riverbed, allowing water to flow freely downstream without obstruction.

## 5. Conclusion As a flexible, eco-friendly, and cost-effective alternative to traditional dams, rubber dams play a vital role in modern water resource management. Their ability to balance functionality (flood control, water storage) with ecological protection (fish migration, river health) makes them ideal for sustainable development—whether in rural irrigation systems, urban landscape projects, or large-scale hydraulic engineering. With ongoing innovations in smart monitoring and material technology, rubber dams will continue to be a key solution for addressing global water challenges.

Send Inquiry to This Supplier

You May Also Like

-

Inflatable Rubber DamUS$ 290 - 300MOQ: 20 Meters

-

Manufacturer Supplies Inflatable and Water-filled Rubber Dams, Waterproof River Landscape Rubber Sluice Gates, Airbag-style Rubber DamsUS$ 290 - 300MOQ: 20 Meters

-

Rubber Dam, Inflatable Type, River-blocking and Water-retaining, Seamless, High-temperature ResistantUS$ 290 - 300MOQ: 20 Meters

-

Direct Supply From Rubber Dam Manufacturers, Seamless Overlapping Air Shield Dam, Complete Specifications, Customized as NeededUS$ 290 - 300MOQ: 20 Meters

-

Rubber Dam Manufacturer, Seamless Splicing, Customized as Needed, Small Inflatable Rubber Dam, Water-injection Rubber Dam, Dam Bag Water BarrierUS$ 290 - 300MOQ: 20 Meters

-

Rubber DamUS$ 290 - 300MOQ: 20 Meters

-

Inflatable and Water-filled Rubber Dam for River Waterproofing and Landscape Water ControlUS$ 290 - 300MOQ: 20 Meters

-

Inflatable Rubber Dam, Custom 7.5-meter-high Rubber Water Dam, Seamless JointUS$ 290 - 300MOQ: 20 Meters

-

Durable Inflatable Rubber Dam for Agricultural/Flood ControlUS$ 290 - 300MOQ: 20 Meters

-

Water Injection Boom Reusable Inflatable Rubber Flood Dam Inflatable Water Filled Tube Flood BarriersUS$ 290 - 300MOQ: 20 Meters