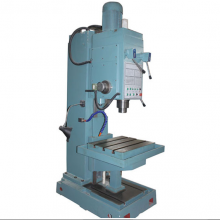

Convenient Efficient Square Column Drilling Machine With a Vertically Oriented Spindle for Metalworking

1. Base: The sturdy base provides stability and support for the entire machine, ensuring minimal vibration during operation.

2. Column: The vertical column supports the drill head and table, allowing for height adjustment to accommodate different workpiece sizes.

3. Drill Head: Houses the motor, spindle, and drilling mechanism. The spindle can be adjusted for speed and depth, depending on the material and hole size.

4. Worktable: The adjustable table can be moved vertically and sometimes rotated or tilted to position the workpiece accurately. It often includes slots for clamping the workpiece securely.

5. Spindle and Chuck: The spindle rotates the drill bit, which is held in place by a chuck. The chuck can be tightened or loosened to change drill bits as needed.

6. Feed Handle: Used to manually lower the spindle and drill bit into the workpiece, providing precise control over the drilling process.

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point. High quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machines need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q4. What about the quality control?

A4: All raw materials we use are quality controlled.Workers will take care of every detail when handling production and packaging.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones for free.

Q6. Is the packaging form?

A6: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q7. How long is your delivery cycle?

1) In the case of stock, we can deliver the machine within 7 days.

3) In the case of customization, we can deliver the machine within 20-25 days.

Send Inquiry to This Supplier

You May Also Like

-

New Arrival Worm Drive Hose Clamp Making Machine Hose Clamp Assembly MachineUS$ 28500 - 31500MOQ: 1 Piece

-

Custom Slotting Machine B5020 B5032 Vertical Slotting Machine Planer Machine for SaleUS$ 5800 - 7800MOQ: 1 Piece

-

Hot Selling New Design DK7745 Cnc Wire Cut Edm Machine Fast-moving Wire Cutting Machine for MetalUS$ 4500 - 5500MOQ: 1 Piece

-

Hot Selling 2D 3D Fully Auto CNC Metal Steel Bar Solid Wire Bending Machine 3 Axis 5 Axis Wire Forming MachineUS$ 21000 - 25000MOQ: 1 Piece

-

High Speed 3 Ton 3.5 Ton 5 Ton Good Quality Diesel Forklift With Side Shift TransmissionUS$ 8199 - 8999MOQ: 1 Piece

-

New Arrival VMC1160 3-Axis CNC Vertical Machining Center Machine Centro De Mecanizado CncUS$ 20500 - 22500MOQ: 1 Piece

-

High Quality Cement Conveyor Pump Equipment Fine Aggregate Concrete Hydraulic Pumps Concrete Pump TruckUS$ 4899 - 5699MOQ: 1 Piece

-

High Quality Wall Concrete Spray Plastering Machine Sand Mortar Spray Machine Cement Diesel PowerUS$ 1399 - 1600MOQ: 1 Piece

-

Hot Selling 455CNC Automatic Aluminum Cutting Aluminum Saw Machine Servo Controlled Aluminum Pipe Profile Cutting SawUS$ 6250 - 6850MOQ: 1 Piece

-

Hot Selling 4.2m 4.8m 5.5m Car Roof Shade Cover Automatic Car Umbrellas With Remote ControlUS$ 80 - 100MOQ: 1 Piece