I. Overview

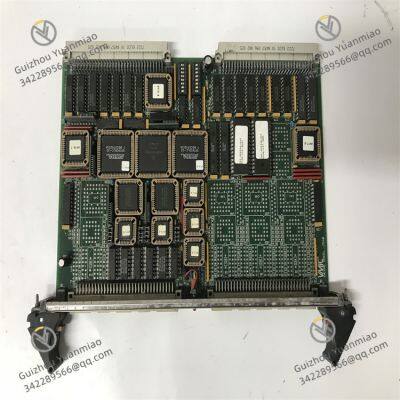

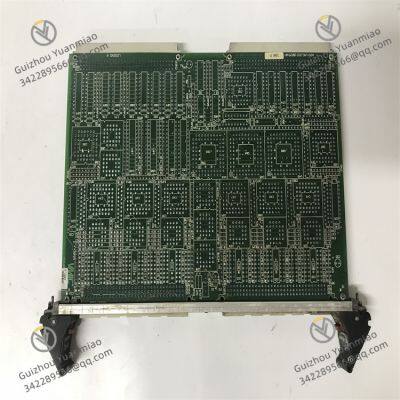

GE VMIVME-2540 is a high-performance industrial control board based on VME bus technology, which is widely used in the field of industrial automation control. As a mature industrial computer bus standard, VME bus features high reliability, high data transmission rate and good expandability. VMIVME-2540 makes full use of these advantages and can provide powerful processing and control capabilities for various complex industrial control systems.

This board integrates advanced processors and rich interface resources, and can serve as a core control unit in the field of industrial control, used to realize real-time monitoring, control and management of various equipment and parameters in the industrial production process. Whether in traditional heavy industry fields such as electric power, metallurgy and chemical industry, or in modern industrial scenarios such as automated production lines and smart factories, VMIVME-2540 can play a role stably and reliably, providing a strong guarantee for the efficient and safe operation of industrial production.

II. Technical Parameters

Processor: It adopts a high-performance embedded processor, such as possibly being equipped with a Motorola PowerPC series processor. The clock frequency is usually above several hundred megahertz, with strong data processing capability and computing speed, which can quickly respond to and process various complex control algorithms and real-time data.

Memory Configuration: It is equipped with a certain capacity of Random Access Memory (RAM), generally ranging from tens of megabytes to hundreds of megabytes, used for temporarily storing data and intermediate results during program operation. At the same time, it may include Read-Only Memory (ROM) or flash memory, used for storing the firmware program and configuration information of the board, ensuring that the board can start and run normally after being powered on.

VME Bus Interface: It complies with the VMEbus standard, supports 32-bit or 64-bit data transmission, and has a high data transmission rate, usually up to tens of megabytes per second. It can realize high-speed data exchange and communication with other VME bus devices, ensuring the cooperative work between various components of the system.

I/O Interfaces: It provides rich input/output interfaces, including digital input/output (DI/DO) interfaces, analog input/output (AI/AO) interfaces, etc. The digital interfaces can be used to connect various switching signals, such as the switch status of sensors and the control signals of relays; the analog interfaces can be used to collect continuously changing physical quantity signals such as temperature, pressure and flow, and output analog control signals to drive actuators.

Communication Interfaces: It may include Ethernet interfaces and serial communication interfaces (such as RS-232, RS-485, etc.). The Ethernet interface is used to realize high-speed data communication with upper computers or other network devices, supporting TCP/IP and other network protocols, facilitating remote monitoring and data transmission; the serial communication interface can be used to connect some traditional serial devices to realize point-to-point data transmission.

Working Environment: The operating temperature range is usually wide, generally able to work normally between 0 - 60 degrees Celsius, and can adapt to the relatively harsh temperature environment of industrial sites. The relative humidity is usually in the range of 5% - 95% (no condensation), with a certain moisture-proof capability. At the same time, it has a certain anti-vibration and anti-shock performance to cope with mechanical vibration and shock in industrial sites.

III. Functional Features

Powerful Processing Capability: Benefiting from the high-performance processor and optimized hardware architecture, VMIVME-2540 has strong real-time data processing and computing capabilities. It can quickly execute complex control algorithms, timely respond to various changes in the industrial production process, and ensure the accuracy and timeliness of control.

Good Expandability: Based on VME bus technology, this board can be easily expanded and integrated with other VME bus devices (such as I/O modules, communication modules, storage modules, etc.). Users can flexibly configure the system according to actual application needs to build industrial control systems that meet different scales and functional requirements, with strong flexibility and expandability.

High Reliability and Stability: It adopts industrial-grade components and design standards, and has undergone strict testing and verification, with high anti-interference ability and reliability. It can work stably in harsh environments such as strong electromagnetic interference, temperature fluctuations and vibration in industrial sites, reducing production interruptions caused by equipment failures, and improving the continuity and stability of industrial production.

Rich Interface Functions: It has various types of I/O interfaces and communication interfaces, which can seamlessly connect with various industrial equipment, sensors and actuators, realizing the collection and control of multiple parameters in the industrial production process. At the same time, through the communication interface, it can realize information interaction and data sharing with upper computers and other control systems, facilitating the centralized monitoring and management of the entire industrial production process.

Strong Real-Time Performance: It has good real-time response capability, which can meet the strict requirements for real-time performance in the field of industrial control. It can quickly process various events and data from the site, issue control commands in a timely manner, ensure that the industrial production process proceeds according to the predetermined rhythm and requirements, and improve production efficiency and product quality.

IV. Common Faults and Solutions

The board cannot start

Fault Phenomenon: After the board is powered on, there is no response, the indicator light is not on, and it cannot start normally.

Possible Causes: Power supply failure, such as unstable power supply voltage, poor contact of the power interface or damaged power supply; damaged or lost firmware program on the board; hardware failure of the board, such as damage to key components such as the processor and memory.

Solutions: First, check the power supply situation, use a multimeter to measure whether the power supply voltage is within the specified range, check whether the power interface is firmly connected, and replace the power supply for testing if necessary. If the power supply is normal, try to reflash the firmware program of the board. If the above methods are ineffective, it may be a hardware failure of the board, and it is necessary to contact professional maintenance personnel for repair or replace the board.

Communication Failure

Fault Phenomenon: The board cannot communicate normally with the upper computer or other devices, and data transmission is interrupted or incorrect.

Possible Causes: Poor contact of the communication interface, such as loose or disconnected connections of network cables, serial communication cables, etc.; incorrect setting of communication protocols, such as incorrect configuration of parameters such as IP address, port number and baud rate; communication lines are interfered with or damaged; failure of the communication module on the board.

Solutions: Check the connection of the communication lines to ensure that the interfaces are firmly connected; check and verify the communication protocol parameter settings to ensure they are consistent with those of the communication partner; check whether the communication lines are damaged or aged, and replace them if necessary. If the above methods are ineffective, the communication module of the board may be faulty and needs to be repaired or replaced.

I/O Interface Failure

Fault Phenomenon: Unable to collect input signals or output control signals normally, such as no response to digital input, inaccurate analog collection data, and output signals unable to drive actuators.

Possible Causes: Poor contact or disconnection of the connection line between the I/O interface and external equipment; failure of external equipment, such as damaged sensors and faulty actuators; damage to the I/O interface circuit on the board.

Solutions: Check the connection line between the I/O interface and external equipment to ensure it is firmly connected and not disconnected; replace the external equipment for testing to determine if it is an external equipment failure. If the external equipment is normal, the I/O interface circuit of the board may be faulty, and professional personnel are required for repair or replacement of the board.

Abnormal Data Processing

Fault Phenomenon: The data collected by the board is inaccurate, the control algorithm is executed incorrectly, or abnormal output results occur.

Possible Causes: Memory failure of the board, leading to errors in data storage and reading; loopholes or errors in the control program; data transmission or processing errors caused by external interference.

Solutions: Test the board's memory and replace it if there is a fault; check and debug the control program to fix loopholes and errors in the program; take anti-interference measures, such as adding shielding and grounding, to reduce the impact of external interference on the board.