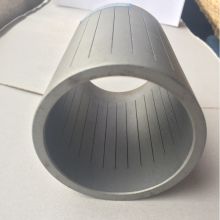

High-Flow Slotted Production Liner Tubing

Manufacturer: Dongying Mingde Petroleum Technology Co., Ltd.

Engineered for Maximum Productivity

Dongying Mingde's high-flow slotted production liner tubing delivers superior hydrocarbon and water recovery through scientifically optimized designs. Featuring 1-6% precisely controlled open area, our CFD-modeled slot patterns achieve higher flow rates than industry standards while maintaining absolute sand control. Ideal for heavy oil, dewatering operations, and high-volume aquifers where efficiency drives profitability.

The Gold Standard for Water Wells

As Dongying Mingde's flagship optimal water well screen liner, this solution combines precision engineering:

- Aquifer-Specific Slotting: 0.008"-0.060" widths tailored to formation gradation

- Biofouling Defense: Electropolished 304/316L stainless steel (Ra<0.8μm)

- Zero-Corrosion Guarantee: 30+ year service life in mineral-heavy groundwater

- Open Area Mastery: 1-6% configurable for optimal flow/sand control balance

Proven in municipal supply wells across Shandong Province and agricultural projects throughout the Yellow River Basin.

Precision-Tailored Dimensions

Dongying Mingde delivers perfectly sized tailored length OD/ID slotted liner with unmatched manufacturing accuracy:

No wellbore deviation too challenging – we manufacture to your exact wellbore geometry.

Technical Specifications

Flow Engineering:

- Venturi Slot Design: Accelerates entry while reducing pressure drop

- Open Area Control: Precisely calibrated 1-6% for strength/flow balance

- Turbulence Reduction: Helical patterns for laminar flow

Customization Capabilities:

- Slot widths: 0.008" to 0.250"

- Slot patterns: Straight/Staggered/Helical/Keystone

- End preparations: BTC/LTC/NUE/EUE/Flush

Critical Applications

1. High-Yield Water Systems

- Municipal water supply wells

- Agricultural irrigation projects

- Mine dewatering operations

2. Enhanced Oil Recovery

- Steam flood injection wells

- Coalbed methane production

- Heavy oil reservoirs

3. Specialized Environments

- Geothermal brine extraction

- Environmental remediation wells

- Aquifer storage and recovery (ASR)

Why Choose Dongying Mingde

After standardizing on Mingde's tailored liners, our Shengli Oilfield waterflood project saw 30% increased injection rates and zero screen failures over 24 months."

> – Drilling Manager, Sinopec Shengli Oilfield

Quality Certification:

✅ API Q1 Monogram

✅ ISO 9001:2015 Certified

✅ 100% Hydrostatic + Helium Testing

✅ Full Material Traceability (EN 10204 3.1)

Precision Manufacturing Process

1. Plasma Slotting: CNC-controlled maintain ±0.002" slot tolerance

2. Dimensional Control: OD/ID verified with laser micrometers

3. Quality Validation:

- 3D scanning of slot patterns

- Flow testing with formation-specific media

- Mechanical property verification

Ordering Specifications

Submit well parameters for engineered solutions:

- Casing/tubing dimensions (OD/ID requirements)

- Formation analysis report (sand size/distribution)

- Flow rate targets and temperature profile

- Connection type preference

All Mingde liners include:

- Slot configuration optimization report

- Material certification package

- Installation torque guidelines

- Custom handling fixtures

Send Inquiry to This Supplier

You May Also Like

-

Plasma Slotted Liner PipeNegotiableMOQ: 1000 Pieces

-

Slotted Liner PipeNegotiableMOQ: 1000 Pieces

-

Punch Liner Pipe Perforated Liner PipeUS$ 100 - 150MOQ: 100 Meters

-

Sand Control Slotted Liner PipeNegotiableMOQ: 1000 Pieces

-

Plasma Slotted Liner PipeNegotiableMOQ: 1000 Pieces

-

API Slotted Tubing PipeUS$ 100 - 150MOQ: 100 Meters

-

API Slotted Casing PipeUS$ 100 - 300MOQ: 100 Meters

-

Slotted Liner Pipe Well Completion Sand Control Gravel PackUS$ 30 - 400MOQ: 100 Meters

-

Slotted Liner Slotted Casing Pipe Slotted TubingUS$ 30 - 300MOQ: 100 Meters

-

Plasma Slotted LinerUS$ 30 - 300MOQ: 100 Meters